Description

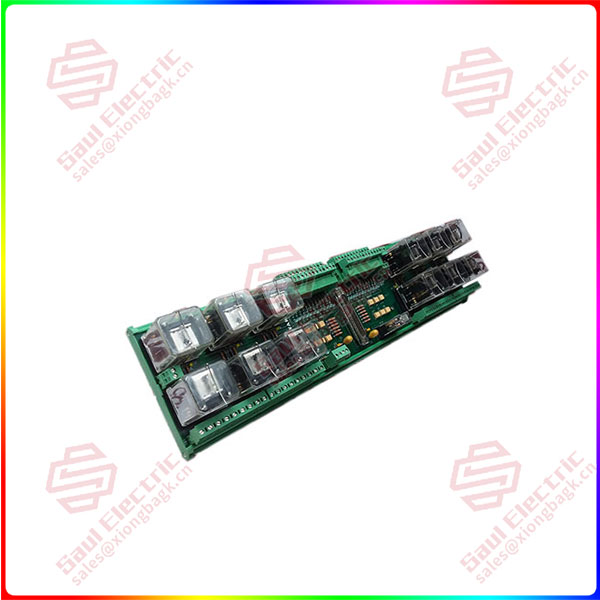

WOODWARD 9905-969 — I/O Expansion / Signal Conditioning Module

Product: 9905-969, I/O Module

Manufacturer: Woodward, Inc.

Primary Application: A specialized signal conditioning and interface module designed for Woodward 505/505XT Digital Speed Control Systems. It expands and adapts input/output capabilities, typically for interfacing with specific sensors or actuators in turbine control applications.

1. Core Overview & Positioning

The Woodward 9905-969 is an expansion module that belongs to the 9905 series of accessory modules for the 505/505XT governors. Unlike universal digital I/O cards, modules in the 9905 series are often designed for specific signal types or functions.

The -969 suffix strongly suggests this module is configured as a Signal Conditioner or Isolated Interface, most likely for handling analog signals such as:

-

4-20 mA process signals (e.g., for pressure, temperature transmitters).

-

Thermocouple (T/C) or Resistance Temperature Detector (RTD) inputs for direct temperature measurement.

-

Isolated analog outputs for driving chart recorders or meters.

-

Frequency or speed inputs from magnetic pickups or proximity sensors.

Key Philosophy: It bridges the gap between the governor’s low-voltage logic and potentially noisy, high-voltage, or non-standard field signals, providing isolation, scaling, and conversion.

2. Key Features & Functions

-

Signal Conditioning: Converts field-level analog signals (e.g., 4-20mA, 0-10V, thermocouple mV) into a clean, scaled digital or analog signal readable by the 505/505XT main processor.

-

Electrical Isolation: Provides galvanic isolation between the field wiring and the sensitive control electronics of the 505, protecting against ground loops, noise, and voltage transients.

-

Scalable Inputs/Outputs: Allows configuration of input ranges (e.g., 4-20mA representing 0-1000 psi) and output scaling to match engineering units.

-

Dedicated Function: Based on the 9905-xxx numbering, it is likely pre-configured at the factory for a specific signal type (e.g., «9905-969 Thermocouple Input Module»).

-

Integration: Plugs directly into a dedicated slot on the 505/505XT backplane or connects via a designated interface, becoming a seamless part of the control system.

3. Common Technical Specifications (Inferred from Series)

-

Compatibility: Designed exclusively for use with Woodward 505 and 505XT Digital Speed Controllers.

-

Signal Type: Likely Analog Input or Analog Output. The most common configurations are:

-

Analog Input Module: Accepting 4-20mA, 0-10V, RTD (Pt100, Pt1000), or common thermocouple types (J, K, T, E).

-

Analog Output Module: Providing an isolated 4-20mA or 0-10V output proportional to a controller variable.

-

-

Channels: Typically provides one or two isolated channels.

-

Power: Powered from the 505/505XT backplane.

-

Connection: Screw terminal blocks for field wiring.

4. System Integration & Configuration

-

Role: Acts as a specialized peripheral device for the 505/505XT. It allows the governor to directly monitor process variables (like steam header pressure, bearing temperature) or output analog signals (like valve demand to a recorder) without needing an external PLC or signal converter.

-

Configuration: The scaling and parameters for this module are configured within the 505/505XT’s internal software using the front panel keys or, more commonly, Woodward’s Toolkit configuration software. The 505’s control logic can then use these scaled values for control, alarms, or logging.

-

Wiring: Field devices (sensors) are wired directly to the module’s terminals.

5. Typical Applications

Used to integrate process variables directly into the turbine governor’s control and monitoring system:

-

Steam Turbine Control: Monitoring steam pressure or temperature for inlet pressure control or override functions.

-

Turbine Monitoring: Directly connecting bearing temperature RTDs or vibration transmitters (4-20mA) for alarms or trip functions.

-

Process Interface: Providing an analog output of turbine speed or valve position to a plant Distributed Control System (DCS).

-

Compressor Control: Monitoring suction/discharge pressures for anti-surge or performance control algorithms within the 505.

Reviews

There are no reviews yet.