Description

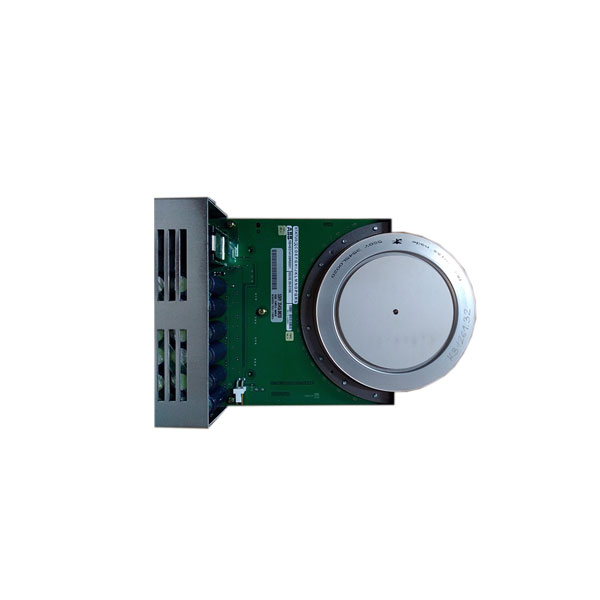

ABB SYNCHROTACT 6 SYN6302 — Automatic Synchronizing Relay

Product: SYN6302 — Automatic Synchronizing Relay

Series: SYNCHROTACT 6

Manufacturer: ABB

Primary Application: An advanced automatic synchronizing relay designed for the safe and precise synchronization of generators to a busbar or busbar to busbar in power generation plants, industrial facilities, and marine electrical systems.

1. Core Overview & Positioning

The ABB SYN6302 is a key member of the SYNCHROTACT 6 family of synchronizing and protection relays. It automates the entire synchronization process, ensuring that a generator (or an incoming source) is connected to a live busbar only when critical parameters—voltage, frequency, and phase angle—are within safe limits. This prevents mechanical stress and electrical transients, protecting equipment and enhancing grid stability.

Key Philosophy: It replaces manual synchronization or less advanced relays, providing a fully automated, reliable, and precise solution that complies with international grid connection standards.

2. Key Features & Functions

-

Fully Automatic Synchronization: Continuously measures voltage, frequency, and phase angle of both sides (Generator and Busbar). It calculates the difference and, when all conditions are met, issues a close command to the circuit breaker at the precise moment for a smooth connection.

-

Advanced Synchronization Modes:

-

Generator to Busbar (Standard).

-

Busbar to Busbar (Check Synchronizing).

-

Dead Busbar Closing: Allows closing onto a de-energized bus (dead bus) or a bus with residual voltage (live bus logic).

-

-

Intelligent Control Strategies:

-

Can send raise/lower pulses to the generator’s governor (for speed/frequency matching) and raise/lower pulses to the Automatic Voltage Regulator (AVR) (for voltage matching).

-

Features adaptive control algorithms for efficient and fast synchronization.

-

-

Integrated Protection & Safety Functions:

-

Sync-Check (ANSI 25): Permissive function to prevent closing if conditions are not met.

-

Voltage Differential Protection (ANSI 60): Protects against closing with excessive voltage difference.

-

Built-in safety timers and interlocks to prevent repeated failed attempts.

-

-

User Interface & Configuration:

-

Front-panel LCD display and navigation keys for local operation, real-time parameter viewing (slip frequency, phase angle, voltage difference), and setting adjustments.

-

Configured using dedicated software (e.g., CAP 505 or PCM600) for detailed parameterization.

-

-

Communication: Equipped with communication ports (RS485, Ethernet) supporting standard protocols like Modbus RTU/TCP, IEC 61850, for integration into plant DCS/SCADA systems.

3. Common Technical Specifications

-

Voltage Inputs: Typically two three-phase voltage inputs (for Generator side and Busbar side). Common nominal voltages: 100-120V AC or 200-240V AC (via VTs).

-

Frequency Range: Wide operating range (e.g., 40-70 Hz).

-

Synchronizing Accuracy: High-precision closing, typically < ±2° phase angle and < 0.3 Hz frequency difference at the moment of closing.

-

Output Relays: Multiple programmable output relays for:

-

Close Command (pulsed output).

-

Raise/Lower Governor.

-

Raise/Lower AVR.

-

Alarms and Status signals.

-

-

Binary Inputs: For external commands (Start Sync, Enable, Block) and status feedback.

-

Power Supply: Wide-range DC or AC supply (e.g., 24-48 V DC, 110-230 V AC/DC).

-

Mounting: DIN-rail or panel mounting.

4. System Integration

-

Role in a Generator Control System: It works in conjunction with the Governor (speed control) and Automatic Voltage Regulator (AVR). Upon a start command, it takes over the fine-tuning of frequency and voltage before issuing the final closing command.

-

Typical Wiring: Connects to:

-

Voltage Transformers (VTs) on the Generator and Busbar.

-

Circuit breaker’s closing coil.

-

Governor and AVR raise/lower interfaces.

-

Plant control system via communication or hardwired I/O.

-

-

Commissioning: Requires careful setting of parameters such as allowable voltage difference, frequency difference (slip), phase angle window, circuit breaker closing time, and pulse durations for governor/AVR control.

5. Typical Applications

-

Power Plants: Synchronizing diesel, gas, hydro, or steam turbine generators to a plant bus or the utility grid.

-

Industrial Plants: For cogeneration (CHP) generators connecting to the factory electrical system.

-

Marine & Offshore: Synchronizing generator sets on ships or offshore platforms.

-

Utility Substations: For busbar coupling or line synchronization.

Reviews

There are no reviews yet.