Description

B&R 5AP920.1043-K01 — Technical Overview

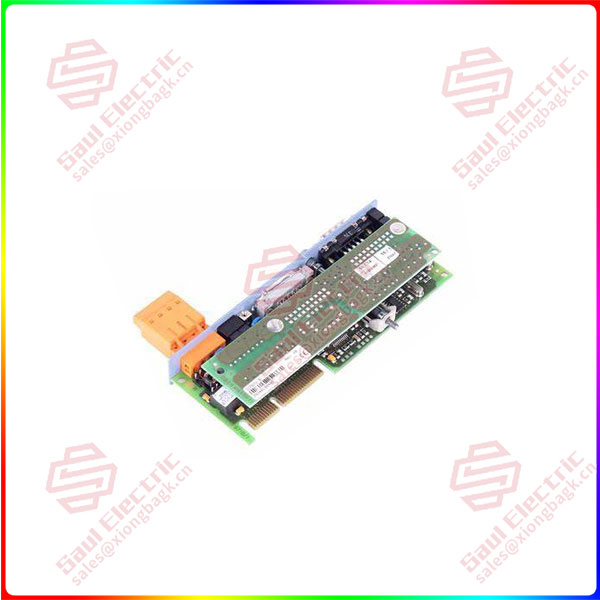

Product: 5AP920.1043-K01, X20 System I/O Module

Manufacturer: B&R Industrial Automation (now part of ABB)

Product Line: X20 System (Modular I/O and Control)

Primary Application: A specialized analog/digital I/O module for the B&R X20 distributed I/O system, designed for industrial automation applications requiring mixed signal acquisition and output capabilities.

1. Product Identification & Series Context

This module belongs to B&R’s X20 system — a modular, high-performance I/O system known for its flexibility and robustness in industrial environments.

2. Technical Specifications & Features

Module Characteristics:

-

Form Factor: Compact module designed for DIN-rail mounting in X20 system racks

-

Bus Interface: Integrated X2X Link (B&R’s high-speed backplane bus)

-

Status Indicators: LED indicators for power, status, and channel activity

-

Isolation: Channel-to-channel and channel-to-bus isolation for noise immunity

Typical I/O Configuration:

Based on similar 1043-series modules, this likely includes:

-

Analog Inputs: 4 or 8 channels

-

Voltage inputs: 0-10V, ±10V

-

Current inputs: 0-20mA, 4-20mA

-

Resolution: 16-bit

-

-

Digital Inputs: 4 or 8 channels

-

24V DC sinking/sourcing

-

Filtering options

-

-

Digital Outputs: 4 channels

-

24V DC, 0.5A per channel

-

Short-circuit and overload protected

-

Performance Specifications:

-

Sampling Rate: Typically 1 ms per channel (analog)

-

Accuracy: ±0.1% of full scale (analog)

-

Update Time: < 1 ms (digital)

-

Electrical Isolation: 500V AC between channels and bus

3. Communication & Integration

System Compatibility:

-

Controller Integration: Compatible with B&R X20 CPUs (e.g., CP1486, CP1586)

-

Network Protocols: Supports B&R’s POWERLINK, Ethernet POWERLINK, or PROFINET via system bus

-

Configuration Tool: Programmed via B&R Automation Studio

Communication Features:

-

X2X Link Speed: Up to 100 Mbps

-

Deterministic Communication: Suitable for real-time control applications

-

Hot-swappable: Can be replaced during operation (system-dependent)

4. Application Scenarios

Typical Use Cases:

-

Process Control Systems

-

Analog signal acquisition from sensors (temperature, pressure, flow)

-

Digital status monitoring

-

Actuator control via digital outputs

-

-

Machine Automation

-

Mixed signal processing in packaging machines

-

Production line monitoring and control

-

Quality inspection systems

-

-

Energy Management

-

Power monitoring applications

-

Environmental parameter acquisition

-

Industry Applications:

-

Manufacturing and assembly lines

-

Food and beverage processing

-

Pharmaceutical production

-

Automotive manufacturing

-

Renewable energy systems

5. Installation & Configuration

Mounting Requirements:

-

System Base: X20 base module (e.g., X20BBxx series)

-

Power Supply: X20 power supply module required

-

Space Requirements: Typically 1-2 slots in X20 rack

Configuration Steps:

-

Hardware Setup:

-

Mount on DIN rail

-

Insert into X20 base module

-

Connect field wiring to front connectors

-

-

Software Configuration (Automation Studio):

(* Example configuration structure *) MODULE MixedIO_Module VAR AnalogInput1 : REAL; DigitalOutput1 : BOOL; END_VAR -

Parameter Settings:

-

Analog input ranges

-

Filter constants

-

Scaling parameters

-

Diagnostic settings

-

6. Technical Documentation & Resources

Required Documentation:

-

Data Sheet: 5AP920.1043-K01 specific specifications

-

X20 System Manual: General system information

-

Automation Studio Help: Configuration guidelines

Key Parameters to Verify:

-

Input voltage/current ranges

-

Digital input voltage levels

-

Output current ratings

-

Update times and filtering options

7. Important Notes & Precautions

Safety Considerations:

⚠️ Warning:

-

Ensure proper grounding and shielding

-

Follow local electrical codes and regulations

-

Use appropriate wire gauges and types

-

Implement proper overcurrent protection

Compatibility Notes:

-

Requires compatible X20 base module

-

Firmware must match Automation Studio version

-

Check voltage ratings for field devices

Programming Considerations:

-

Configure in Automation Studio (version 4.0 or higher recommended)

-

Implement proper error handling

-

Consider sampling rates for control applications

8. Troubleshooting & Diagnostics

Common Issues:

-

Module Not Recognized:

-

Check bus connection

-

Verify power supply

-

Confirm module seating

-

-

Analog Signal Issues:

-

Verify input range settings

-

Check for proper grounding

-

Validate sensor compatibility

-

-

Digital I/O Problems:

-

Confirm voltage levels

-

Check load currents

-

Verify wiring connections

-

Diagnostic Tools:

-

LED status indicators

-

Automation Studio online monitoring

-

System event logs

9. Ordering & Replacement Information

Related Components:

-

Base Module: X20BBxx (specific type required)

-

Power Supply: X20PSxx00

-

Connectors: X20xx98-1 (field wiring connectors)

-

Terminals: Appropriate for wire gauge

Replacement Guidelines:

-

Use identical part number for replacement

-

Backup configuration before replacement

-

Note firmware version compatibility

-

Document all settings before removal

Reviews

There are no reviews yet.