Description

SST 5136-PFB-104 — PROFIBUS Communication Module

Product: 5136-PFB-104, PROFIBUS Interface Module

Manufacturer: SST (Solid State Technology, Inc.) – now part of Rockwell Automation (acquired and integrated into their product lines)

Primary Application: A PROFIBUS DP (Decentralized Peripherals) interface module designed to act as a slave device, allowing automation equipment (PLCs, drives, I/O) to communicate on a PROFIBUS DP network. It’s commonly used as a bridge or adapter card in systems that need to connect non-PROFIBUS native devices to a PROFIBUS network.

1. Core Overview & Function

The SST 5136-PFB-104 is part of SST’s extensive line of industrial communication interface products. Its primary role is to translate between a device’s internal bus or protocol and the standard PROFIBUS DP fieldbus.

Key Function: It acts as a PROFIBUS DP-V1 Slave, appearing as a standard slave node on the PROFIBUS network. It exchanges data (input and output words) between the PROFIBUS master (e.g., a Siemens S7 PLC, a Rockwell ControlLogix with a master card) and the host device it is plugged into.

2. Key Features & Characteristics

-

PROFIBUS DP-V1 Slave: Supports both cyclic data exchange (for real-time process data) and acyclic services (for parameterization, diagnostics, and alarms).

-

Flexible Integration: Typically designed as a plug-in module or daughter card that fits into a specific host device’s proprietary slot or bus.

-

Dual-Port Memory Interface: Often uses a dual-port RAM interface to facilitate fast, low-level data exchange with the host device’s CPU.

-

Configurable Data Size: The amount of input and output data (the «process image») exchanged over PROFIBUS is configurable via software, typically up to 244 bytes each way, to match the host device’s requirements.

-

Diagnostics: Provides comprehensive diagnostic information accessible via PROFIBUS (slave status, module faults) to the network master.

-

Non-Volatile Memory: Stores configuration (like the PROFIBUS node address and parameters) permanently.

3. Typical Host Systems & Form Factor

The «5136» series modules are device-specific. The 5136-PFB-104 is not a standalone device; it must be installed into a compatible host. Common host platforms include:

-

Drive Controllers: To give a variable frequency drive (VFD) or servo drive a PROFIBUS DP port.

-

Third-Party PLCs or PACs: To allow a non-PROFIBUS controller to connect to a PROFIBUS network as a slave.

-

Specialized I/O or Measurement Devices: To network devices like weigh scales, barcode readers, etc.

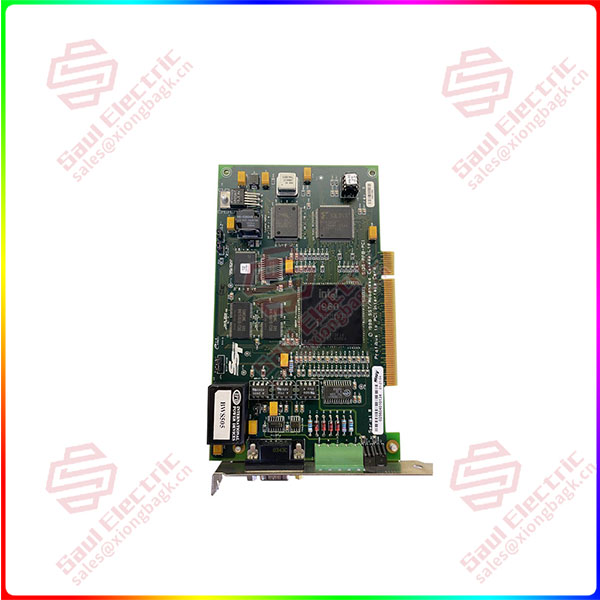

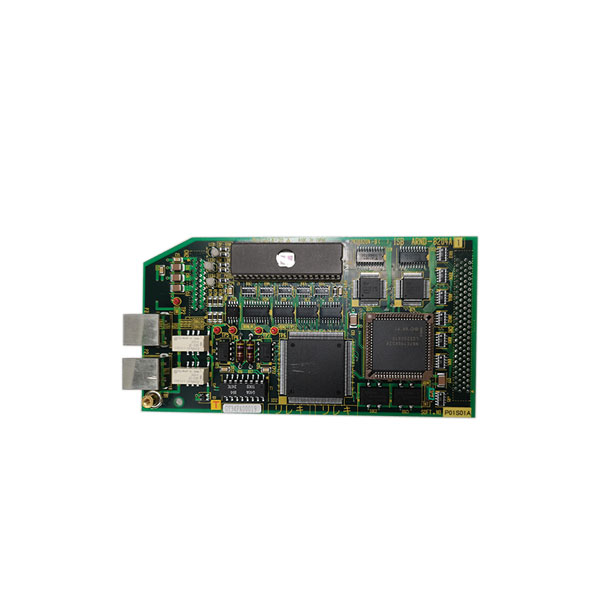

Form Factor: It is usually a small printed circuit board (PCB) with a PROFIBUS connector (9-pin D-sub) and a connector or edge for plugging into the host device’s motherboard.

4. Technical Specifications

-

PROFIBUS Interface:

-

Protocol: PROFIBUS DP-V1 slave.

-

Connector: 9-pin D-sub female (standard).

-

Baud Rate: Auto-detect or configurable from 9.6 kbps to 12 Mbps.

-

Address: Set via rotary switches or software (address range 1-125).

-

-

Host Interface: Proprietary to the host device, but commonly a parallel bus or dual-port RAM interface.

-

Configuration: Requires SST configuration software (e.g., SST PROFIBUS DP Configuration Tool) to set up the data mapping between the host device’s internal registers and the PROFIBUS input/output image.

-

Power: Typically powered directly from the host device (e.g., +5V DC).

-

LED Indicators: Status (RUN/ERR), PROFIBUS network activity (BF), and power.

5. System Integration & Configuration Workflow

-

Physical Installation: The module is plugged into its dedicated slot on the host device (e.g., a drive).

-

Hardware Settings: The PROFIBUS node address is set using DIP switches or rotary switches on the module itself.

-

Software Configuration:

-

Using the SST configuration software, a «Device Description File» (GSD file) for the specific host device (e.g.,

MyDrive_V3.gsd) is imported into the PROFIBUS master’s configuration tool (e.g., Siemens STEP 7, TIA Portal). -

In the master’s software, the module appears as a slave. The user configures the size of the input and output data areas (e.g., 4 bytes in, 4 bytes out).

-

The configuration is downloaded to the PROFIBUS master.

-

-

Data Mapping: Within the host device (e.g., the drive’s own programming software), the user maps internal parameters (speed reference, actual speed, fault codes) to the specific PROFIBUS input/output words defined in the GSD configuration.

6. Common Applications

-

Integrating Non-PROFIBUS Drives: Adding a Rockwell PowerFlex drive to a Siemens PROFIBUS-controlled production line.

-

Legacy System Integration: Connecting older or specialized equipment to a modern PROFIBUS-based DCS or SCADA system.

-

Building Networked I/O Islands: Creating a cluster of devices that communicate via a local backplane, with the SST module acting as the gateway to the wider PROFIBUS network.

Reviews

There are no reviews yet.