Description

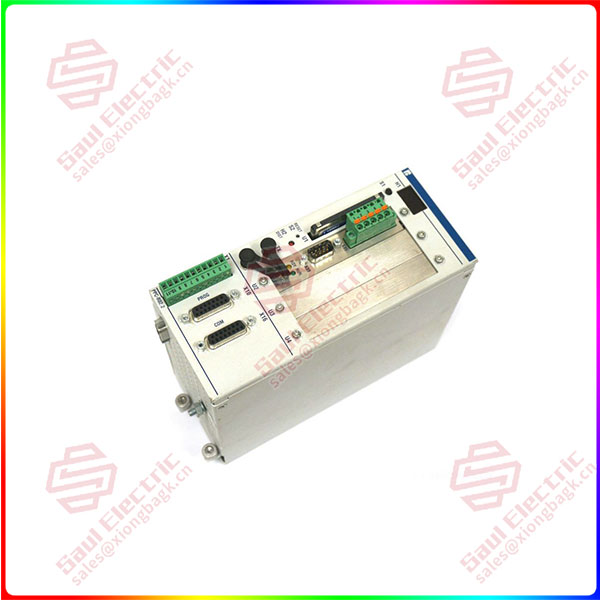

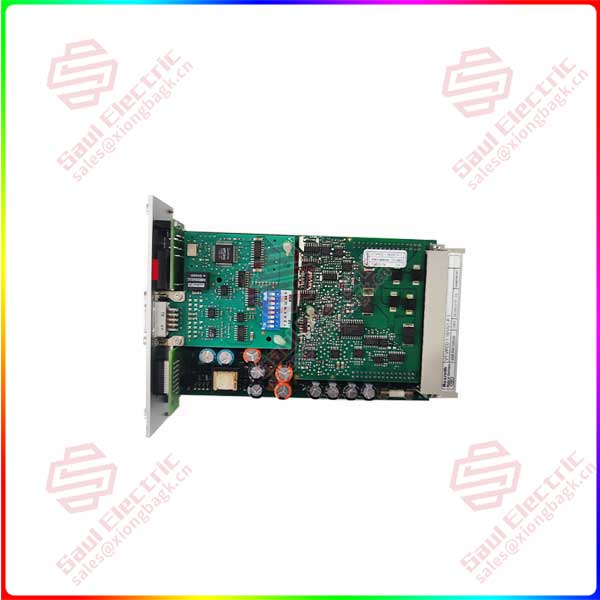

BOSCH REXROTH PPC-R22.1N-T-NN-P2-NN-FW VM11 — Technical Overview

Product: PPC-R22.1N-T-NN-P2-NN-FW VM11, Industrial Panel PC / Programmable Performance Controller

Manufacturer: Bosch Rexroth

Product Line: IndraControl (IndraMotion Machine Control Platform)

Primary Application: A high-end, modular industrial PC designed to serve as the central controller and HMI (Human-Machine Interface) for complex, multi-axis automation systems, combining PLC, motion control, robotics, and visualization in a single, robust device. Typical applications include high-speed packaging machines, plastic injection molding machines, metal forming presses, and advanced assembly systems.

1. Core Overview & Positioning

The Bosch Rexroth PPC-R22.1N is the flagship of the IndraControl PPC (Programmable Performance Controller) R series. It is not merely an HMI panel but a fully integrated control computer that consolidates multiple functions into one unit, eliminating the need for separate PLC, motion controller, and visualization hardware.

Key Philosophy: It embodies the «Software CNC» and «Centralized Control» concept, where all machine logic, complex kinematics, and operator visualization are processed on a single, powerful industrial PC, communicating via real-time fieldbuses (like EtherCAT or PROFINET IRT) with distributed servo drives and I/O.

2. Key Features & Functions

-

Unified Control Platform: Runs the complete Bosch Rexroth IndraWorks software suite, allowing for integrated engineering of:

-

PLC Logic (IEC 61131-3, e.g., Structured Text, Function Block Diagram).

-

Motion Control & CNC (handling hundreds of axes, complex interpolations, robotics).

-

Advanced HMI/SCADA (with multi-touch and gesture support).

-

Data Management & Analytics.

-

-

High-Performance Industrial Computing: Based on a powerful Intel multi-core processor (defined by the

P2code), capable of executing demanding real-time control tasks alongside Windows-based visualization. -

Brilliant Industrial Display: Features a 22.1-inch TFT display with multi-touch (

T) capability, designed for high brightness, contrast, and visibility in harsh industrial environments. -

Modular I/O and Communication: The rear panel includes slots for plug-in IndraControl modules, enabling flexible configuration of fieldbus masters (EtherCAT, PROFINET, PROFIBUS, Ethernet/IP) and other interfaces.

-

Robust Construction: Built to withstand industrial environments with a front panel rated at IP65 (dust-tight and protected against water jets), resistant to vibration, shock, and wide operating temperatures.

-

Integrated Safety (Option): Can be extended with safety modules to implement safety functions (e.g., Safe Torque Off, Safe Stop) up to SIL 3 / PL e, all programmable within IndraWorks.

3. Technical Specifications (Typical for this Configuration)

-

Processor: Intel Core i5 or i7 (Generation defined by order year and

P2code), multi-core. -

Memory: 4-8 GB DDR4 RAM (expandable, defined by first

NN). -

Storage: SSD, 128-256 GB (defined by second

NN). -

Display: 22.1″ TFT LCD, typically WXGA (1280 x 800) or higher, 16:10 aspect ratio, multi-touch (projected capacitive or resistive).

-

Interfaces:

-

Front: USB port(s), potentially function keys.

-

Rear: Multiple USB, Gigabit Ethernet, DVI-I, COM, and slots for IndraControl modules.

-

-

Fieldbus: Configurable via plug-in modules (e.g., X20 interface for EtherCAT master, PROFINET controller).

-

Operating System: Windows 10 IoT Enterprise 64-bit.

-

Software Framework: Bosch Rexroth IndraWorks.

-

Protection Rating: Front panel IP65/NEMA 4, rear IP20.

-

Power Supply: 24 V DC (standard industrial voltage).

4. System Integration & Development

-

Engineering: All development—PLC logic, motion profiles, HMI screens, and safety logic—is done within the unified IndraWorks Engineering environment on a separate development PC.

-

Deployment: The complete project is compiled and downloaded to the PPC-R via Ethernet. The PPC-R then executes the real-time control kernel (under Windows) and the HMI runtime.

-

Drive & I/O Network: Acts as the central master for a real-time EtherCAT or PROFINET IRT network, controlling IndraDrive servo drives, IndraControl I/O stations, and third-party devices with exceptional determinism and synchronization.

-

Role: Serves as the singular «central brain» for high-performance machinery, enabling advanced applications like robotic tooling, electronic line shafts, and complex CNC interpolation.

5. Typical Applications

-

High-Speed Packaging Machines: Where precise coordination of numerous servo axes (fillers, cappers, labelers) and complex HMI are required.

-

Plastics Machinery: Injection molding machines with closed-loop hydraulic control and robotic part handling.

-

Metal Forming & Stamping: Presses and transfer lines requiring synchronized multi-axis motion and safety.

-

Advanced Assembly & Testing Systems.

-

Machine Tools requiring integrated CNC and HMI.

Reviews

There are no reviews yet.