Description

WOODWARD 8440-1409 — Technical Overview

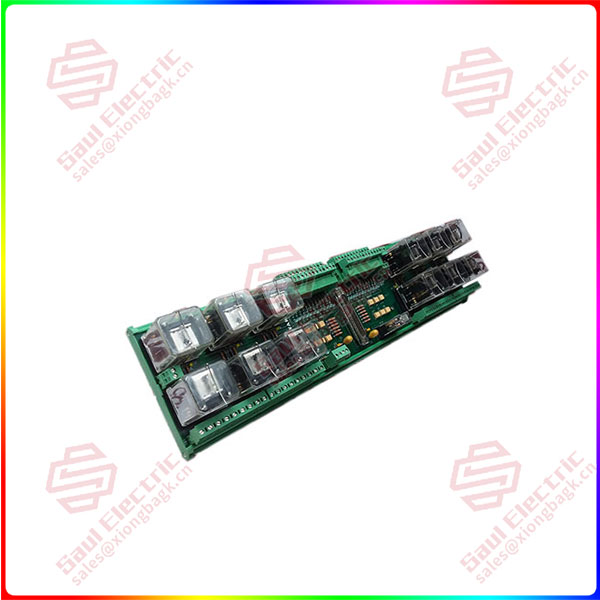

Product: 8440-1409, Servo Driver / Actuator Control Module

Manufacturer: Woodward, Inc.

Primary Application: A digital servo driver/amplifier module designed for precise closed-loop control of electro-hydraulic actuators (EHAs) or electro-mechanical actuators used in gas turbine, steam turbine, and large engine control systems for positioning fuel valves, inlet guide vanes, and other critical control elements.

1. Core Overview & Positioning

The Woodward 8440-1409 is a component within Woodward’s extensive 8440 series of control modules. It functions as a dedicated servo controller, bridging the gap between a primary digital governor (like a Woodward 723PLUS or NetCon) and the final actuating device. Its primary role is to execute high-speed, closed-loop position control, ensuring the actuator accurately follows commands from the main controller.

Key Concept: It forms the inner loop of a cascade control system, translating a low-power position command into a high-power, modulated output to drive a servo valve coil or actuator motor, while continuously monitoring actual position via feedback from an LVDT/RVDT sensor.

2. Key Features & Functions

-

Closed-Loop Position Control: Implements a fast digital control algorithm (typically PID-based) to maintain precise actuator position by comparing the command signal with real-time feedback from a Linear Variable Differential Transformer (LVDT) or Rotary Variable Differential Transformer (RVDT).

-

Dual Input Processing:

-

Command Input: Accepts an analog position setpoint (typically ±10V DC or 4-20mA) from the primary speed/load controller.

-

Feedback Input: Interfaces with an AC-excited LVDT/RVDT attached to the actuator to measure actual position.

-

-

High-Current Output Drive: Provides a modulated current output (typically in the range of ±40 mA to ±200 mA) capable of driving the inductive coil of a proportional or servo-proportional hydraulic valve.

-

Integrated Diagnostics & Protection:

-

Continuous monitoring of LVDT/RVDT health (signal level, frequency, phase).

-

Coil and driver stage fault detection (open circuit, short circuit, over-current).

-

Detection of excessive position error (deviation between command and feedback).

-

-

Field-Configurable Parameters: Allows tuning of servo loop gains (Proportional, Integral, Derivative), current limits, LVDT excitation, and response characteristics via configuration software (Woodward Toolkit) to match the specific actuator dynamics.

-

Communication Interface: Typically includes a Woodward proprietary communication port (e.g., for Gov. Bus/NetBus) for integration with the primary controller, configuration, and diagnostics.

3. Common Technical Specifications

-

Part Number Context: The

-1409suffix specifies this exact variant’s hardware configuration, input/output ranges, and firmware features. -

Command Input: Configurable analog input, typically ±10V DC or 4-20mA.

-

Feedback Input: Designed for industry-standard AC LVDT/RVDTs (common excitation: 3 Vrms @ 2.5 kHz or 5 Vrms @ 5 kHz).

-

Output Drive: Current output suitable for driving standard servo valve coils.

-

Power Supply: Requires external DC power, commonly ±15V DC for control circuitry and a separate +24V to +80V DC for the power output stage.

-

Physical Form: A printed circuit board (PCB) assembly designed for mounting in a Woodward control cabinet or a dedicated drive chassis.

-

Status Indicators: LEDs for power, status, and fault conditions.

4. System Integration & Configuration

-

Role in Control Hierarchy: Acts as a slave drive unit to a primary Woodward Digital Governor. It executes precise position commands but relies on the master for the overall control strategy.

-

Configuration Software: Entirely configured and tuned using Woodward Toolkit PC software. The process involves:

-

Hardware Setup: Defining I/O signal types and scaling.

-

LVDT Calibration: Mapping the LVDT’s electrical output to the actuator’s physical stroke (min/max travel).

-

Servo Tuning: Adjusting PID and dynamic compensation parameters to achieve optimal step response—fast and stable without oscillation—specific to the connected actuator.

-

-

Integration: Installed in a slot within a Woodward control rack or enclosure. It interfaces with the actuator’s LVDT and servo valve, and communicates with the primary controller over a dedicated bus.

5. Typical Applications

This module is critical in applications requiring precise and reliable actuation for prime mover control:

-

Gas Turbine Control: Driving fuel metering valves, gas control valves, and inlet guide vanes (IGVs).

-

Steam Turbine Governing: Positioning governor valves and intercept valves.

-

Diesel Engine Control: Governing actuators for fuel injection systems.

-

Compressor Control: Driving anti-surge control valves.

Reviews

There are no reviews yet.