Description

MOOG G771K208A — Technical Overview

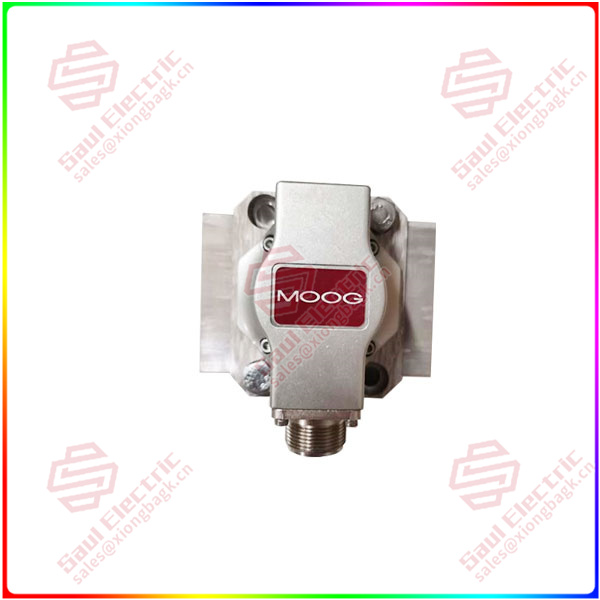

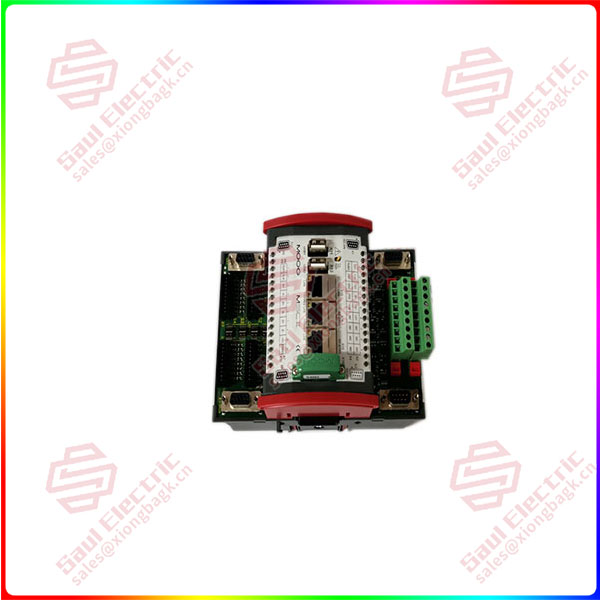

Product: G771K208A, Servo Control Module / Electronic Drive Unit

Manufacturer: Moog Inc.

Primary Application: A high-performance servo drive or servo controller module designed for precise, closed-loop control of electro-hydraulic servo valves (EHSV), electro-mechanical actuators (EMA), or other proportional/servo devices in demanding motion control applications within aerospace, defense, and industrial sectors.

1. Core Overview & Positioning

The Moog G771K208A is a specialized electronic control unit from Moog, a world leader in precision motion control technology. It functions as the «brain» of a servo system, responsible for executing complex control algorithms to command and precisely regulate the position, velocity, or force of an actuator.

Key Philosophy: It translates a low-power command signal (from a host computer, PLC, or joystick) into a high-power, conditioned drive signal suitable for driving the torque motor or voice coil of a servo valve or actuator. It forms the critical link in a high-performance motion control loop, enabling the speed, accuracy, and stability Moog systems are known for.

2. Key Features & Functions

-

Closed-Loop Control: Implements advanced PID (Proportional-Integral-Derivative) control algorithms, often with additional feedforward, notch filtering, and compensation for nonlinearities. It continuously compares the command signal with feedback from a transducer (e.g., LVDT, RVDT, resolver) and adjusts its output to minimize error.

-

High-Power Output Stage: Contains a power amplifier capable of delivering the required current (often in the range of tens of mA to several Amperes) and voltage to drive inductive servo valve coils or motor windings.

-

Dual-Channel Input Processing:

-

Command Input: Accepts an analog command signal (typically ±10V DC, 4-20mA) or a digital command (e.g., via serial bus).

-

Feedback Input: Accepts signals from a position/velocity feedback device (LVDT, RVDT, tachometer, encoder) to close the loop.

-

-

Comprehensive Diagnostics & Protection: Features extensive onboard monitoring for:

-

Coil/Driver fault detection (over-current, short circuit).

-

Feedback sensor failure (open/short circuit, loss of signal).

-

Overtemperature protection.

-

Command-Feedback monitoring (excessive error).

-

-

Field Configurability: Control parameters (gains, limits, filter settings, scaling) are typically adjustable via configuration software, DIP switches, or potentiometers to tune the system for the specific actuator and load dynamics.

-

Robust Construction: Designed for operation in harsh environments, often conformally coated and built to withstand vibration, shock, and wide temperature ranges, especially for aerospace/defense variants.

3. Model Number Analysis & Specifications

Inferred Technical Specifications (Must be verified with Moog datasheet):

-

Output Drive: Current output suitable for driving specific Moog servo valve coils (e.g., G631, G761 series valves).

-

Command Input: ±10V DC, differential.

-

Feedback Input: AC LVDT/RVDT (e.g., 3 Vrms @ 2.5 kHz or 5 kHz excitation).

-

Power Supply: Requires external DC power rails (e.g., ±15V DC for logic, +28V or higher for output stage).

-

Communication: May include a service/setup port (RS-232/422) for configuration and monitoring.

-

Form Factor: Likely a printed circuit board (PCB) assembly or a module in a dedicated enclosure for chassis mounting.

4. System Integration & Application

-

Role in Control Loop: It is the servo controller/amplifier in a standard motion control chain:

-

Motion Controller → Command Signal → G771K208A.

-

G771K208A → Drive Signal → Servo Valve / Actuator.

-

Actuator moves load.

-

Position Transducer (LVDT) → Feedback Signal → G771K208A (closing the loop).

-

-

Configuration: Requires precise tuning of the servo loop gains and calibration of the feedback transducer (null and span adjustment) to achieve optimal performance (fast response without oscillation). This is typically done using Moog’s configuration software (e.g., Moog Servo Driver Suite) or a portable programmer.

-

Typical Integration: Found in the control cabinet of high-performance systems, interfacing with a main system controller (like a Moog MCU-2000 Multi-Axis Controller or a custom PLC).

5. Typical Applications

-

Aerospace: Flight control surface actuation (primary flight controls, thrust vectoring), fuel metering control, landing gear testing.

-

Defense: Turret and weapon positioning systems, missile fin control, simulator motion bases.

-

Industrial:

-

Fatigue & Structural Testing: Driving hydraulic actuators in test frames (MTS, Instron systems often use Moog valves and controllers).

-

Industrial Automation: Precision control of presses, rollers, and other machinery requiring high dynamic response.

-

Robotics: High-force actuation in advanced robotic systems.

-

Reviews

There are no reviews yet.