Description

HONEYWELL FC-TSRO-0824 — Room Temperature Controller

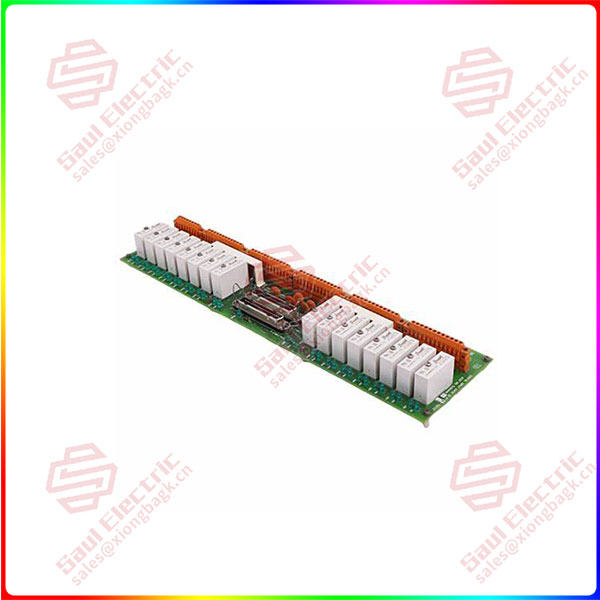

Product: FC-TSRO-0824, Room Temperature Controller Module

Manufacturer: Honeywell International Inc.

Product Line: Excel 5000 / WEBs Building Management System (BMS)

Primary Application: A dedicated application-specific controller (ASC) designed for room-level temperature control in building automation systems, typically used to manage fan coil units (FCUs), unit ventilators, heat pumps, or other terminal heating/cooling units in commercial, institutional, and residential spaces.

1. Core Overview & Positioning

The Honeywell FC-TSRO-0824 is a member of Honeywell’s Excel 5000 family of application-specific controllers, specifically designed for terminal unit control. The «TSRO» designation likely stands for Temperature Sensor & Relay Output. It provides a compact, pre-programmed solution for controlling a single thermal zone.

Key Philosophy: It provides a complete, self-contained control solution for a room or zone, integrating temperature sensing, user interface (via a connected thermostat or room sensor), and relay outputs to command heating/cooling devices. It is designed for standalone operation or seamless integration into a building management system.

2. Key Features & Functions

-

Embedded Control Sequences: Contains pre-programmed, optimized control logic for terminal units, typically implementing a heating/cooling PID algorithm with configurable setpoints, deadbands, and operating modes (Heat/Cool/Auto/Off).

-

Integrated Temperature Sensing: Includes a local input for a temperature sensor (e.g., a 10kΩ NTC thermistor or a Honeywell specific sensor) to measure room air temperature. This eliminates the need for a separate sensor in many applications.

-

Dedicated Outputs for Terminal Units: Features a set of relay outputs designed to directly control the actuators in a fan coil unit or similar device:

-

Fan Speed Control: Typically 2 or 3 relays to select fan speeds (High, Medium, Low, Off).

-

Heating/Cooling Valve Control: Relays to energize heating valve (normally closed) and cooling valve (normally closed) actuators.

-

Auxiliary Output: May include an extra relay for additional control (e.g., a pipe heater, alarm).

-

-

User Interface Integration: Designed to connect to a wall-mounted room sensor/thermostat (like Honeywell T7350, T7370 series) that provides the user with temperature display, setpoint adjustment, and mode selection. The controller itself is usually installed remotely (e.g., above a ceiling tile near the unit).

-

Communication Capability: Equipped with a C-Bus communication port for integration into a Honeywell Excel 5000 or WEBs BMS network. This allows for:

-

Remote monitoring of space temperature and setpoint.

-

Remote adjustment of setpoints and operating modes.

-

Alarm monitoring (e.g., filter alarm from a connected differential pressure switch).

-

Scheduling and global overrides from the BMS supervisor.

-

-

Standalone Operation: Can function independently, with all control logic executed locally based on the connected room sensor.

3. Model Number Breakdown & Specifications

Typical Technical Specifications:

-

Power Supply: 24V AC or 24V DC (standard for HVAC controls).

-

Inputs:

-

Room Temperature Input: For a 10kΩ NTC thermistor or similar (often via connections for a remote room sensor).

-

Binary Inputs (Optional): May include a digital input for a filter alarm switch or an occupancy sensor.

-

-

Outputs:

-

Relay Outputs: Typically 5 or 6 SPDT (Form C) relays. Common configuration:

-

3 relays for Fan Speed (High, Medium, Low).

-

2 relays for Heating Valve and Cooling Valve.

-

1 relay for Auxiliary/Alarm.

-

-

Relay Rating: Typically 5A, 240V AC resistive.

-

-

Communication: C-Bus port for network integration.

-

Configuration: Configured using Honeywell CARE software to set parameters like PID gains, temperature setpoints, fan speed logic, and equipment timers (e.g., fan off delay).

-

Mounting: DIN-rail mountable enclosure, typically installed in a control cabinet near the terminal unit.

4. System Integration & Wiring

Control Logic:

-

-

The controller reads the room temperature from the connected sensor.

-

Compares it to the active setpoint (from the local user interface or BMS).

-

Based on the mode (Heat/Cool) and the deviation, it energizes the appropriate valve relay (heating or cooling) to modulate the water flow via the valve actuator.

-

Simultaneously, it controls the fan speed based on the call for heating/cooling or a user-selected fan speed (Continuous, Intermittent).

-

-

BMS Integration: When networked, the BMS can read the room temperature, override the local setpoint for energy savings, and monitor the unit’s status.

5. Typical Applications

-

Fan Coil Unit (FCU) Control: The most common application, controlling 2-pipe or 4-pipe FCUs in hotel rooms, offices, and apartments.

-

Unit Ventilator Control: In classrooms and similar spaces.

-

Heat Pump Control: For water-source or air-source heat pump terminals.

-

Radiant System Control: Controlling pumps and valves in radiant heating/cooling panels.

Reviews

There are no reviews yet.