Description

Product Overview

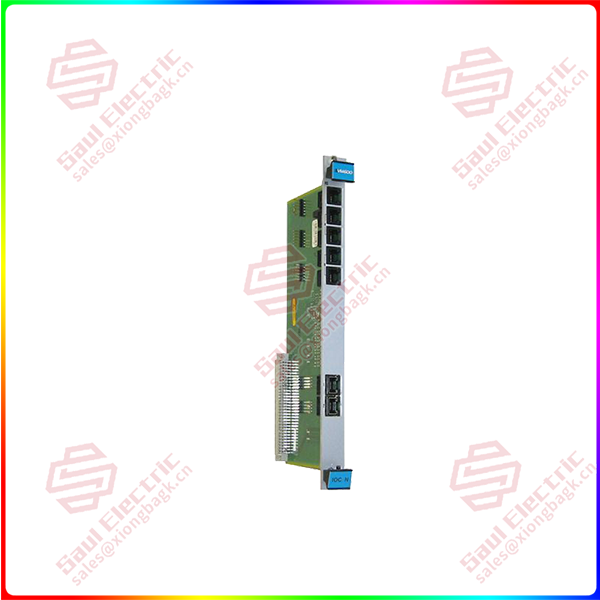

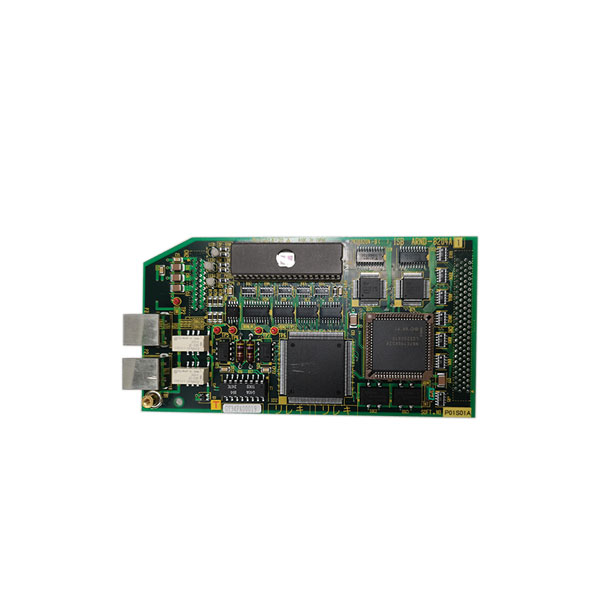

The VIBRO-METER VM600 IOCN PNR200-566-000-112 is a highly advanced and versatile Input/Output Controller Network module within the VIBRO-METER VM600 machinery condition monitoring and protection system, now part of the Baker Hughes Bently Nevada portfolio. This specific IOCN variant represents a sophisticated, network-ready signal conditioning and data acquisition unit designed to serve as a distributed intelligence node. Its primary function is to aggregate, condition, digitize, and pre-process signals from a vast array of sensors monitoring the health of critical rotating equipment—such as turbines, compressors, pumps, and fans—and then transmit this data over a high-speed industrial network to central monitoring processors or asset management systems. The IOCN excels in handling mixed signal types, including inputs from eddy current proximity probes (for vibration and position), accelerometers, velocity sensors, RTDs for temperature, and 4-20 mA transmitters for process variables.

The extended part number

PNR200-566-000-112specifies its exact configuration, detailing the number of channels, input types, and integrated network communication capabilities (likely supporting Ethernet-based protocols). The value of the VM600 IOCN lies in its distributed architecture, high channel density, and intelligent data management. It moves signal conditioning and initial processing closer to the sensors, reducing analog cable runs, improving signal integrity, and enabling scalable system design. Equipped with onboard processing power, it can perform basic diagnostics, alarming, and data reduction before transmission. For engineers in power generation, oil & gas, and heavy industry, the VIBRO-METER VM600 IOCN is a cornerstone of modern predictive maintenance strategies, providing reliable, high-fidelity data that is essential for protecting assets, optimizing performance, and preventing unplanned downtime through continuous condition assessment.Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

VIBRO-METER VM600 IOCN PNR200-566-000-112

|

|

Manufacturer

|

VIBRO-METER (a Baker Hughes Bently Nevada company)

|

|

System Platform

|

VM600 Machinery Health Monitoring System

|

|

Product Type

|

Networked Input/Output Controller Module (IOCN)

|

|

Primary Function

|

High-density, networked signal conditioning, acquisition, and preprocessing for mixed sensor types.

|

|

Input Channels

|

High-density configuration supporting multiple signal types per module, typically including:

|

-

Dynamic Vibration/Position: Channels for -24V DC / -18V DC eddy current proximity probes (radial vibration, keyphasor, axial position).

-

Casing Vibration: Channels for piezoelectric accelerometers or 4-20 mA velocity transmitters.

-

Temperature: Channels for 2/3/4-wire RTDs (Pt100).

-

Process Analog: Channels for 4-20 mA signals (pressure, differential expansion, etc.).Sensor Power Supply | Provides regulated excitation power for connected sensors (e.g., -24V DC for proximity probes, constant current for RTDs).

VM600-IOCN Signal Conditioning | Includes programmable filtering, integration/differentiation, scaling, and high-quality analog-to-digital conversion (typically 24-bit or higher).Onboard Processing | Microprocessor for signal processing, preliminary diagnostics, and data management.Network Communication | Integrated high-speed industrial Ethernet port(s), supporting protocols such as EtherNet/IP, Modbus TCP/IP, or proprietary Bently Nevada protocols for connection to VM600 racks or directly to plant networks.Diagnostics | Continuous sensor and channel health monitoring: open/short circuit detection, signal validity, module health.Data Outputs | Transmits processed time waveforms, spectra, and processed values (overall levels, temperatures) over the network.Power Supply | Typically 24 V DC, wide-range input suitable for industrial environments.Operating Temperature | 0°C to +70°C (for controlled environments).Certifications | Designed for industrial use, compliant with relevant EMC and safety standards.

Key Features and Advantages

VIBRO-METER VM600 IOCN PNR200-566-000-112 is distinguished by its network-centric, intelligent distributed architecture. A primary advantage is the reduction of long, expensive analog cabling runs. By placing high-quality signal conditioning and digitization close to the machinery (e.g., in a field junction box), only a single Ethernet cable is needed to transmit rich digital data back to the control room, significantly reducing installation cost and complexity while improving noise immunity. The module’s onboard processing capability allows it to perform real-time signal processing (like FFT for spectrum generation) and execute basic alarming logic locally. This reduces the data load on the central processor and enables faster response to local conditions.

Uncompromised signal integrity and advanced diagnostics are engineered into its core. The IOCN provides laboratory-grade signal conditioning tailored to each sensor type, ensuring accurate measurement from delicate low-level signals. Its comprehensive diagnostic suite continuously validates every aspect of the measurement chain—from sensor element and cabling to the internal A/D converter—providing early warning of degrading sensors or developing problems. This proactive health monitoring of the monitoring system itself is critical for maintaining the integrity of protection and predictive maintenance data.

Scalability and seamless enterprise integration are fundamental to its design. The use of standard Industrial Ethernet protocols (like EtherNet/IP) allows the IOCN to communicate seamlessly not only with other VM600 components but also directly with plant DCS, PLCs, and enterprise asset management systems (like Baker Hughes’ System 1™). This makes it a building block for Industry 4.0 and IIoT initiatives. Its modular and high-density design allows a single unit to monitor dozens of points on a machine train, simplifying system architecture. For reliability engineers, the VM600 IOCN delivers a future-proof solution that provides deep, actionable machinery insights, facilitates centralized monitoring of distributed assets, and integrates smoothly into the broader plant digital ecosystem.

Application Areas

The VIBRO-METER VM600 IOCN is deployed in advanced condition monitoring systems for large, critical, and geographically dispersed rotating assets where a distributed, networked architecture provides significant benefits.

Its premier application is in large turbomachinery trains in power generation and oil & gas:

-

Gas Turbine/Steam Turbine-Comprehensor-Generator Trains: Serves as a distributed monitoring node, collecting vibration, position, and temperature data from multiple bearings and casings along the entire train, transmitting it over Ethernet to a central monitoring rack.

-

Offshore Platform & Remote Compressor Stations: Its networked design is ideal for monitoring equipment in remote or inaccessible locations, reducing the need for extensive cabling back to a central control hut.

In process industry applications, it monitors critical pumps, fans, blowers, and mixers across a large plant, enabling centralized condition monitoring from a control room. For wind turbine monitoring, it can be installed in the nacelle to condition signals from gearbox and generator sensors, sending data down the tower via Ethernet. Essentially, the VM600 IOCN is the ideal solution for any application requiring high-fidelity, multi-parameter monitoring of critical machinery where a distributed, digitally networked architecture will reduce cost, improve reliability, and simplify data integration into plant-wide systems.

Related Products

-

VM600 Rack and Central Processing Units (e.g., MPC4): The central processing units that may aggregate data from multiple IOCN modules for advanced analysis and protection.

-

Bently Nevada 3500/42M Proximitor® / 3300 XL Proximity Transducer System: The sensors (probes, proximitors) whose signals are conditioned by the IOCN.

-

Bently Nevada Accelerometers & Velocity Sensors: Vibration sensors compatible with the IOCN‘s dynamic input channels.

-

Industrial Ethernet Switches: Network infrastructure components to connect multiple IOCN modules into a plant network.

-

Baker Hughes System 1™ Software: The enterprise asset performance management platform that is a primary destination for data collected and pre-processed by the IOCN.

-

VM600 Configuration and Management Software: Tools for setting up the IOCN parameters, alarm thresholds, and network configuration.

-

Field Junction Enclosures: Rugged, environmentally rated enclosures for housing the IOCN module near the machinery in the field.

-

Competitor Networked Condition Monitoring I/O (e.g., Emerson CSI 9420, SKF @ptitude): Offer similar networked monitoring functionality.

Reviews

There are no reviews yet.