Description

Product Overview

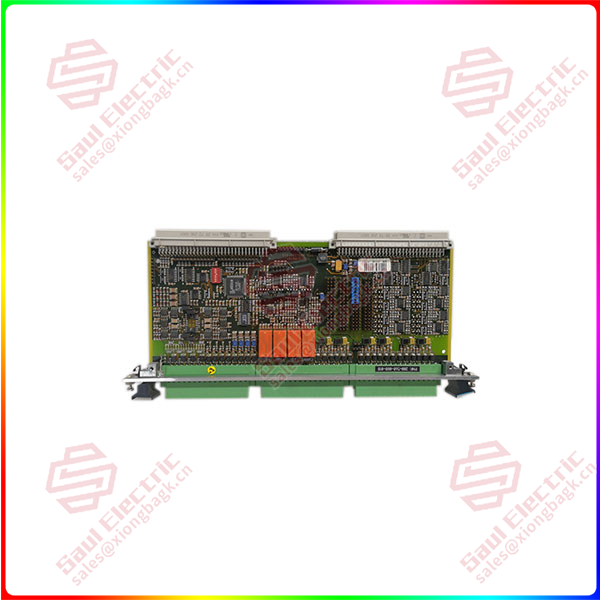

The VIBRO-METER VM600 IOC4T PNR200-560-000-111 is a highly specialized and critical Input/Output Controller (IOC) module within the VIBRO-METER VM600 machinery condition monitoring and protection system, a product line now under the Baker Hughes Bently Nevada portfolio. This module, the IOC4T variant, is specifically designed as a versatile, high-density signal interface and processing unit. Its primary function is to serve as a centralized data acquisition and conditioning hub for a wide array of sensors used in monitoring the health of large rotating equipment, such as gas and steam turbines, compressors, generators, and pumps. The IOC4T accepts raw signals from various transducer types—including proximity probes for radial vibration and position (displacement), accelerometers for casing vibration (velocity/acceleration), RTDs for temperature, and 4-20 mA transmitters for process variables—and converts them into digital data for processing by the system’s monitoring modules (like the Rack Controller) and transmission to higher-level systems.

The extended part number

PNR200-560-000-111specifies the exact hardware configuration, including the number and type of input channels, output options, and any integrated communication interfaces. The value of the VM600 IOC4T lies in its modularity, reliability, and application-specific engineering. It provides essential functions like signal conditioning, filtering, sensor power supply, and fault detection (such as open/short sensor wire diagnostics). By consolidating inputs from numerous sensors into a single, robust unit, it simplifies cabinet wiring, reduces system footprint, and enhances overall signal integrity. For maintenance and reliability engineers in power generation, oil & gas, and heavy industry, the VIBRO-METER VM600 IOC4T forms the foundational hardware layer that ensures continuous, accurate, and reliable acquisition of vital machinery health data, which is essential for condition-based maintenance, predictive analytics, and protection against catastrophic failures.Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

VIBRO-METER VM600 IOC4T PNR200-560-000-111

|

|

Manufacturer

|

VIBRO-METER (a Baker Hughes Bently Nevada company)

|

|

System Platform

|

VM600 Machinery Health Monitoring System

|

|

Product Type

|

Input/Output Controller Module (IOC)

|

|

Primary Function

|

Multi-channel signal conditioning and interface for vibration, position, temperature, and process signals.

|

|

Input Channels

|

High-density configuration, typically supporting multiple types per module. Common configurations include:

|

-

Proximity Probe Inputs: For -24V DC or -18V DC eddy current probes (radial vibration, eccentricity, shaft position).

VM600-IOC4T -

Velocity/Acceleration Inputs: For piezoelectric accelerometers (4-20 mA or mV output).

-

RTD Inputs: For 2/3/4-wire RTDs (Pt100) for bearing/bushing temperature.

-

4-20 mA Inputs: For process variables (pressure, flow, differential expansion).Sensor Power Supply | Provides required excitation voltages/currents to connected sensors (e.g., -24V DC to proximity probes, constant current to RTDs).Signal Conditioning | Includes filtering, integration (for velocity to displacement), scaling, and isolation.Diagnostics | Continuous monitoring for sensor health: open circuit, short circuit, and signal validity.Communication Interface | Connects to the VM600 Rack Controller via a high-speed, proprietary backplane or fieldbus.Outputs | May include analog outputs (4-20 mA) for key parameters and relay outputs for alarms.Power Supply | Powered from the VM600 rack or an external DC source.Operating Temperature | 0°C to +70°C (for installation within a controlled enclosure).Certifications | Designed for industrial use, meeting relevant EMC and safety standards.

Key Features and Advantages

VIBRO-METER VM600 IOC4T PNR200-560-000-111 is distinguished by its versatile, high-density signal integration and robust design. A core advantage is its ability to interface with a diverse mix of critical machinery sensors on a single module. This eliminates the need for multiple, separate signal conditioners, dramatically reducing panel space, wiring complexity, and potential points of failure. The module provides dedicated, optimized conditioning for each sensor type. For example, it supplies the precise -24V DC power required by eddy current probes and includes sophisticated demodulation circuits to extract the vibration and position (gap voltage) signals accurately.

Advanced diagnostic intelligence and signal integrity are fundamental to its reliability. The IOC4T doesn’t just pass signals; it actively monitors the health of each connected sensor and its cabling. It can detect open sensor leads, shorted cables, and loss of power, generating immediate diagnostic alarms. This allows maintenance teams to address sensor issues proactively before data is lost or becomes unreliable, which is crucial for protection systems. The module’s design ensures high noise immunity and galvanic isolation, preserving signal integrity in the electrically noisy environment typical of power plants and industrial facilities.

Seamless integration and scalability within the VM600 ecosystem are key benefits. The module is designed to plug-and-play with other VM600 components (like MPC4 monitoring cards), ensuring data is seamlessly passed to the system for analysis, alarming, and trending. Its configuration is managed through the VM600 engineering software, providing a centralized point for setting sensor parameters, scaling, and alarm thresholds. The modular nature of the VM600 system, with the IOC4T at its I/O core, allows for easy system expansion as monitoring needs grow. For asset managers, this module provides a reliable, intelligent, and scalable foundation for building a comprehensive machinery health monitoring network that supports both protection and predictive maintenance strategies.

Application Areas

The VIBRO-METER VM600 IOC4T is deployed as the primary sensor interface in condition monitoring systems for large, critical rotating equipment across multiple industries.

Its most significant application is in turbomachinery protection and monitoring:

-

Gas & Steam Turbines: Interfaces with radial vibration probes on bearings, keyphasor probes, eccentricity probes, accelerometers on casings, and RTDs for bearing metal and casing temperatures.

-

Centrifugal & Axial Compressors: Monitors vibration, axial position (thrust), and temperatures for surge detection and mechanical protection.

-

Large Pumps and Fans: For vibration and temperature monitoring to detect imbalance, misalignment, and bearing wear.

In power generation, it is integral to monitoring boiler feed pumps, induced/forced draft fans, and generator bearings. For industrial rotating machinery in sectors like oil & gas, petrochemical, and pulp & paper, it provides the monitoring backbone for critical pumps, motors, and gearboxes. Essentially, the VM600 IOC4T is applied wherever a centralized, reliable, and high-fidelity interface is needed to connect a suite of health monitoring sensors to a sophisticated analysis and protection system, typically on assets where unplanned downtime carries severe financial or safety consequences.

Related Products

-

VM600 Rack/Chassis and Power Supply: The hardware platform that houses the IOC4T and other VM600 modules.

-

VM600 Monitoring Processor Cards (e.g., MPC4): The modules that receive conditioned data from the IOC4T and perform vibration analysis, alarm generation, and communication.

-

VIBRO-METER / Bently Nevada Probes & Transducers: The sensors that connect to the IOC4T, such as 3300 XL 8mm Proximity Probes, Accelerometers, and RTDs.

-

VM600 Communication Gateway: For transmitting data from the VM600 system to plant DCS, PLC, or asset management systems (like System 1™).

-

VM600 Configuration Software (e.g., Bently Nevada Configuration Software): Used to set up the IOC4T parameters, channel configuration, and scaling.

-

Bently Nevada System 1™ Software: The enterprise-wide asset performance management platform that is a primary destination for data collected by the VM600 system via the IOC4T.

-

Extension Cables and Junction Boxes: For field wiring between sensors and the IOC4T module in the control cabinet.

-

Competitor Condition Monitoring I/O Modules (e.g., from Emerson/CSI, SKF): Offer similar functionality in different system architectures.

Reviews

There are no reviews yet.