Description

Product Overview

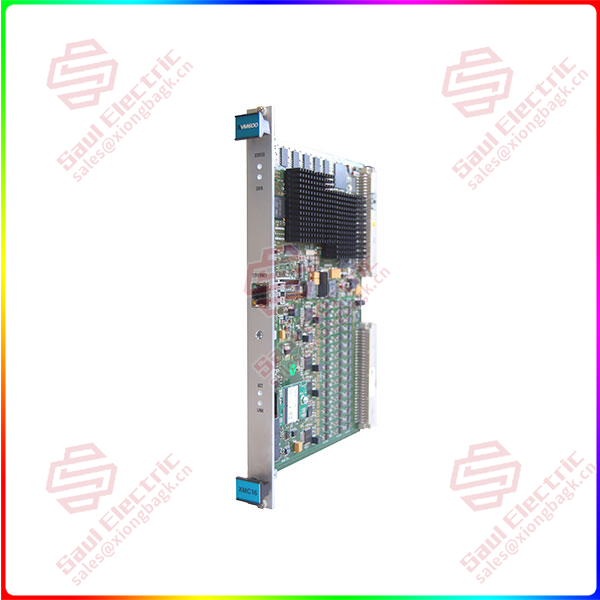

The VIBRO-METER VM600 CMC16 PNR200-530-022-014 is a high-performance, modular Communication Module for Controllers (CMC) within the VIBRO-METER VM600 machinery condition monitoring and protection system, a core product of Baker Hughes Bently Nevada. This specific CMC16 variant serves as the primary communication gateway and network interface for a VM600 rack or processing unit. Its core function is to manage all external data communication, acting as a bridge between the internal VM600 monitoring and processing modules (like the MPC4 processor cards) and external plant networks, control systems, and enterprise software. It handles the aggregation, protocol conversion, and routing of critical machinery health data—including real-time vibration values, spectra, alarm statuses, and waveform data—to destinations such as Distributed Control Systems (DCS), programmable logic controllers (PLCs), and asset performance management platforms like Bently Nevada’s System 1™.

The extended part number

PNR200-530-022-014details its exact hardware configuration, specifying the types and number of communication ports (e.g., Ethernet, serial) and supported protocols. The value of the VM600 CMC16 lies in its versatility, reliability, and security in a networked industrial environment. It enables the seamless integration of deep machinery diagnostics into broader plant operations. By supporting multiple industry-standard protocols simultaneously, it eliminates the need for separate gateways and simplifies system architecture. For maintenance, operations, and reliability teams, the CMC16 is the essential data conduit that transforms a standalone protection monitor into an intelligent node within the Industrial Internet of Things (IIoT), providing the connectivity needed for centralized monitoring, historical analysis, and data-driven decision-making to optimize asset performance and prevent failures.Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

VIBRO-METER VM600 CMC16 PNR200-530-022-014

|

|

Manufacturer

|

VIBRO-METER (a Baker Hughes Bently Nevada company)

|

|

System Platform

|

VM600 Machinery Health Monitoring System

|

|

Product Type

|

Communication Module for Controllers (Gateway/Network Interface)

|

|

Primary Function

|

Protocol conversion, data concentration, and network interfacing for the VM600 system.

|

|

Communication Ports

|

Multiple ports, typically including:

|

-

Ethernet Ports: Dual 10/100/1000Base-T ports for high-speed network connectivity (LAN, SCADA).

-

Serial Ports: RS-232/485 ports for legacy or point-to-point connections.Supported Protocols | Concurrent support for multiple industrial protocols, commonly:

-

Modbus TCP/IP & Modbus RTU: For integration with PLCs and SCADA.

-

OPC DA/UA (Server & Client): For standardized data exchange with Windows-based systems.

-

IEC 60870-5-104 / DNP3: Common in utility and power generation SCADA.

-

Bently Nevada proprietary protocols: For communication with legacy Bently Nevada systems or direct to System 1™.Data Handling | Manages data points from all monitored channels in the rack. Can transmit processed values (overalls, alarms), spectral data, and time waveforms.Processing Power | Onboard processor for protocol handling, data management, and buffering.Integration | Plugs directly into the VM600 rack backplane, providing high-bandwidth access to all monitoring processor (MPC4) data.

CMC16 Security Features | Supports network security standards such as SSL/TLS encryption, VPN passthrough, and configurable firewall rules (depending on firmware).Power Supply | Powered from the VM600 rack backplane.Operating Temperature | 0°C to +60°C (for controlled environments).Certifications | Designed for industrial use, compliant with relevant EMC and safety standards.

Key Features and Advantages

VIBRO-METER VM600 CMC16 PNR200-530-022-014 excels as a multi-protocol gateway and robust network interface. Its primary advantage is the native, concurrent support for key industrial protocols. This allows a single VM600 rack to communicate directly with a diverse ecosystem—sending alarm trips to a plant DCS via Modbus TCP, streaming vibration spectra to an engineering workstation via OPC UA, and simultaneously feeding data to a central System 1™ database. This eliminates layers of external protocol converters, reducing complexity, cost, and potential points of failure.

High data throughput and flexible configuration are central to its value. The module is engineered to handle the significant data volume generated by modern monitoring systems, including the periodic transmission of full spectral and waveform data for diagnostic purposes. Engineers can configure whatdata is sent (e.g., overall values only, or including spectra), to whom(multiple clients simultaneously), and at what frequencyfor each protocol independently. This flexibility prevents network congestion and ensures that each receiving system gets the data it needs in the optimal format. The dual Ethernet ports can be configured for redundancy or for segregating traffic (e.g., one port for plant network, one for dedicated maintenance network).

Enhanced security and reliability are critical for modern networked assets. The CMC16 incorporates features to harden the VM600 system against cyber threats, supporting secure communication methods essential for connecting critical protection systems to enterprise networks. Its robust design ensures continuous operation, and as a module within the VM600 rack, it benefits from the system’s overall high availability (e.g., redundant power supplies). For system integrators, the CMC16 provides a future-proof, secure, and highly capable communication core that maximizes the value of condition monitoring data by ensuring it can be reliably and safely delivered wherever it is needed for operational and business decisions.

Application Areas

The VIBRO-METER VM600 CMC16 communication module is deployed wherever a VM600 monitoring system needs to be integrated into a broader automation and information architecture.

Its primary application is in centralized condition monitoring and protection systems for large industrial facilities:

-

Power Plants (Gas, Steam, Hydro, Nuclear): Integrates turbine and auxiliary equipment monitoring data into the plant DCS for operator awareness and into a central System 1™ server for the reliability engineering team.

-

Oil & Gas Facilities: Connects compressor and pump monitoring systems on offshore platforms or pipeline stations to a central SCADA system for remote operational monitoring and control.

-

Petrochemical & Chemical Plants: Links machinery health data from critical reactors, turbines, and compressors to the plant distributed control system (DCS) and to enterprise asset management (EAM) systems.

It is also essential for original equipment manufacturer (OEM) integrated monitoring on large packaged machinery, where the OEM provides a VM600 system and needs to offer standard interfaces (like Modbus TCP) for easy customer integration. Essentially, the CMC16 is the key enabler for making rich machinery diagnostic data accessible across the organization, from the control room to the maintenance department to corporate engineering.

Related Products

-

VM600 Rack and Monitoring Processor (MPC4): The source of the machinery data that the CMC16 communicates.

-

Bently Nevada System 1™ or APM Software: The primary enterprise software destination for data routed through the CMC16.

-

Plant DCS/SCADA System (e.g., Emerson DeltaV, Siemens PCS 7, Honeywell Experion): The operational control systems that receive alarm and status data via the CMC16.

-

Industrial Network Switches & Firewalls: The network infrastructure to which the CMC16 connects.

-

VM600 Configuration Software: Used to configure the CMC16‘s IP settings, protocol drivers, data mapping, and publishing parameters.

-

Redundant CMC16 Modules: In high-availability configurations, two CMC16 modules may be used for communication path redundancy.

-

Legacy Bently Nevada Communication Interfaces (e.g., 3500/92): The equivalent gateway module for the older 3500 platform, whereas CMC16 is for the VM600 platform.

Reviews

There are no reviews yet.