Description

Product Overview

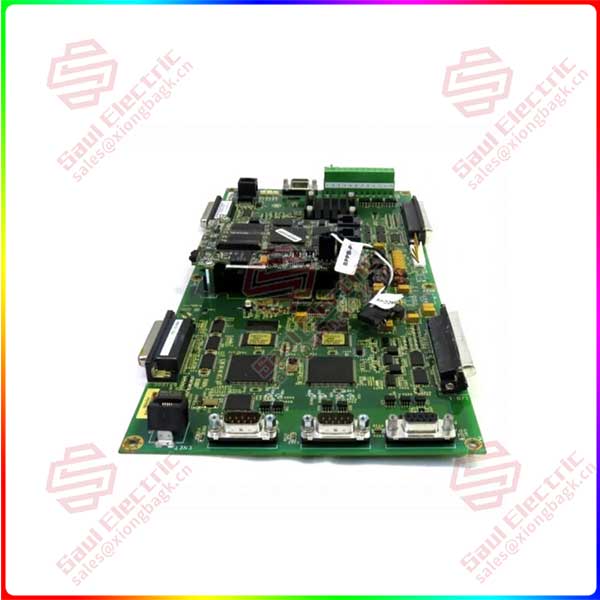

The GE IS210MACCH2AGG is a critical Remote I/O Controller and Communication Interface Module within the General Electric (GE) Mark VI Speedtronic™ gas/steam turbine control system. This specific module, designated as MACC (likely denoting a Modular Analog/Communication Controller or similar), is designed to manage and interface with a cluster of remote input/output (I/O) modules. Its primary function is to serve as a local processor and communication gateway for a set of analog and digital I/O packs that are located away from the main Mark VI controller, typically in a remote termination cabinet or on a turbine skid. The module scans the connected I/O modules, aggregates the data, and communicates with the central Mark VI controller over a high-speed, deterministic control network (such as the VCMI — Versatile Controller Module Interface network). The suffix

H2AGGspecifies a particular hardware revision, firmware version, and configuration, distinguishing it from other MACC variants.The core value of the GE IS210MACCH2AGG lies in its ability to enable a distributed, scalable, and high-performance I/O architecture for the Mark VI system. It decouples I/O acquisition and management from the main controller, allowing I/O to be placed closer to field devices (sensors, actuators) on large turbine packages. This reduces the length and cost of analog signal wiring, improves signal integrity by minimizing noise pickup, and enhances system modularity. The module acts as an intelligent agent, ensuring reliable and timely data exchange between the field and the main control system. For system integrators and turbine engineers, the reliable operation of the MACC module is essential for ensuring that all critical turbine parameters (temperatures, pressures, vibration) are accurately acquired and that all control outputs (to valves, motors) are executed precisely, thereby forming a reliable link in the distributed control chain.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

GE IS210MACCH2AGG

|

|

Manufacturer

|

General Electric (GE)

|

|

System Platform

|

Mark VI Speedtronic™ Turbine Control System

|

|

Product Type

|

Remote I/O Controller / Communication Interface Module

|

|

Primary Function

|

Manages a cluster of remote I/O modules; acts as a network node on the Mark VI I/O network.

|

|

Processor

|

Onboard microprocessor for I/O scanning, data management, and network communication.

|

|

I/O Network Interface

|

Connects to the Mark VI’s high-speed I/O network (typically the VCMI network) to communicate with the main Mark VI controller(s).

|

|

Local I/O Bus

|

Provides a local high-speed parallel or serial bus interface for connecting to multiple GE remote I/O packs (e.g., IS200 series analog input, digital I/O modules).

|

|

Communication Ports

|

May include additional serial ports (RS-232/485) for local configuration, diagnostics, or connection to other devices.

|

|

Memory

|

Onboard memory for storing I/O configuration, data mapping, and application firmware.

|

|

Configuration

|

Fully configured using GE’s ToolboxST engineering software. Configuration includes defining the attached I/O modules, their addresses, scaling parameters, and mapping I/O points to controller database tags.

|

|

Power Supply

|

Powered from the Mark VI rack backplane or from a local power supply within the remote cabinet.

|

|

Operating Temperature

|

0°C to 60°C (standard for control cabinet environments).

|

|

Status Indication

|

Front-panel LEDs indicating power, network status, communication activity, and fault conditions.

|

|

Mounting

|

Designed as a plug-in module for a Mark VI compatible I/O rack or chassis.

|

|

Certifications

|

Designed to meet cULus, CE, and other relevant industrial standards for control equipment.

|

Key Features and Advantages

GE IS210MACCH2AGG excels as a distributed I/O management and network integration unit. Its foremost advantage is enabling a physically distributed control architecture. By allowing I/O to be located in remote cabinets near the turbine auxiliaries (lube oil system, fuel skid, compressor section), it dramatically reduces the amount of long, expensive, and noise-susceptible analog wiring required. The module provides a deterministic and high-bandwidth communication link back to the central controller, ensuring that I/O data is updated with the speed and reliability required for fast turbine control and protection loops.

Local processing and network efficiency are core to its design. The MACC module offloads the task of continuously scanning and managing its local I/O from the main controller. It pre-processes I/O data, handles local diagnostics, and efficiently packages data for network transmission. This reduces the communication load on the main controller’s backplane and the central network, improving overall system performance and scan time consistency. Its robust design ensures reliable operation in the electrically harsh environment typical of power generation facilities.

Scalability, configuration flexibility, and serviceability are key benefits. The use of MACC modules allows the Mark VI system to be easily scaled to manage thousands of I/O points distributed across a large turbine or plant. Configuration is centralized and straightforward using the ToolboxST software. From a maintenance perspective, issues can be isolated to a specific I/O cluster and its MACC controller, simplifying troubleshooting. The module is a Field Replaceable Unit (FRU), and its hot-swap capability (when architected and procedurally supported) allows for replacement with minimal system disruption. In summary, the IS210MACCH2AGG provides the critical intelligence and connectivity that make the Mark VI system a highly flexible, reliable, and scalable platform for complex turbine automation.

Application Areas

The GE IS210MACCH2AGG module is deployed in GE Mark VI control systems for applications requiring distributed I/O architecture, primarily in the power generation and heavy industrial sectors.

Its specific applications include:

-

Gas Turbine Control Systems: Managing I/O on the turbine base frame (for vibration, temperature, speed probes) and on auxiliary skids (fuel, lube oil, cooling).

-

Steam Turbine Control Systems: Handling I/O for governor control, steam valve actuation, and bearing monitoring.

-

Compressor Station Control: In mechanical drive applications where I/O is spread along the driven compressor and its auxiliaries.

-

Balance of Plant (BOP) Systems: Managing I/O for systems like generator cooling, excitation, and switchgear that are monitored/controlled by the turbine controller.

Essentially, the MACC module is used wherever a Mark VI system needs to efficiently gather data from and send commands to field devices that are not located in the same cabinet as the main controller. This is a standard architecture for large, complex rotating equipment packages.

Related Products

-

GE Mark VI Main Controller (e.g., IS200/IS215 series processors): The central controller that communicates with the MACC module over the I/O network.

-

GE Mark VI Remote I/O Modules (IS200 series, e.g., AEPC, DDPC): The analog input, digital I/O, and other specialized modules managed by the MACC in its local cluster.

-

GE Mark VI I/O Network Hardware: Cables, connectors, and terminators for the VCMI network that links MACC modules to the main controller.

-

GE ToolboxST Software: The unified engineering environment for configuring hardware, programming control logic, and setting up the MACC module and its I/O.

-

Remote I/O Cabinet & Power Supply: The enclosure and power distribution system for the remote I/O cluster.

-

Communication Media: Coaxial, twisted-pair, or fiber optic cables used for the I/O network, depending on distance and noise immunity requirements.

Reviews

There are no reviews yet.