Description

Product Overview

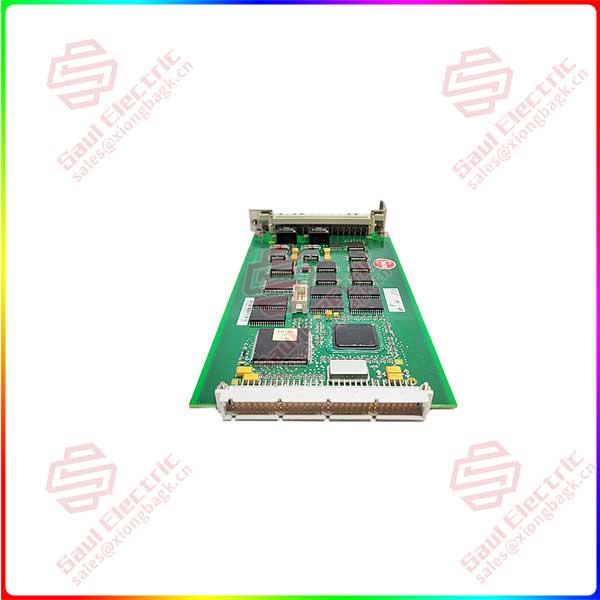

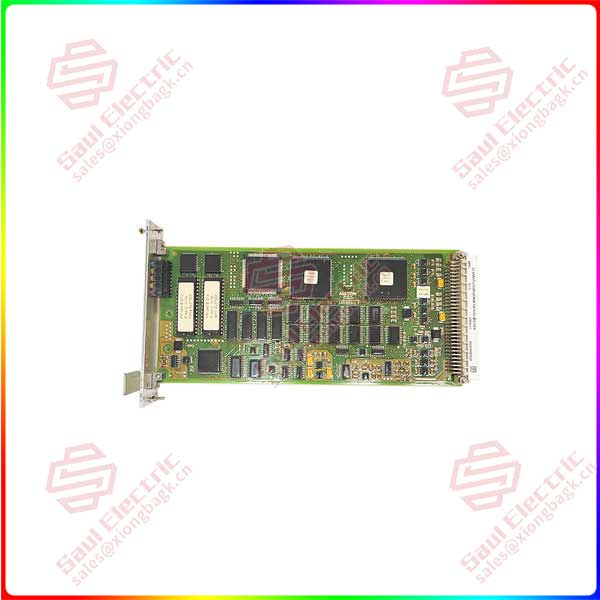

The ALSTOM VCS232 590.043158 is a critical, specialized component within the legacy Alstom (now part of GE Grid or other successor entities) electrical protection and control ecosystem, specifically a Communication Interface Module or a Versatile Control System (VCS) Sub-module. The designation «VCS232» strongly suggests it belongs to a modular control or relay system, possibly the VCS 200 series, and functions as a versatile I/O or communication hub. The suffix

590.043158is a unique part or drawing number. This module’s primary function is to provide configurable digital input/output (I/O) and/or serial communication protocol conversion capabilities, acting as an interface between the core protection/control unit and field devices or other systems. It likely serves as a slave or expansion unit, acquiring status signals (like circuit breaker position, switch status) and outputting control commands (trip, close, alarms), or translating between the proprietary system’s internal protocol and industry-standard protocols like Modbus RTU, IEC 60870-5-101/103, or DNP3 for SCADA integration.The core value of the ALSTOM VCS232 590.043158 lies in its flexibility, reliability, and role in system integration. In substation automation and protection systems of the late 20th and early 21st centuries, such modules were essential for extending the functionality of central units without requiring a complete system redesign. It provides robust galvanic isolation for I/O signals, protecting sensitive control electronics from field-side transients. Its configurability allows it to be tailored to specific application needs, handling a mix of I/O types. For maintenance engineers and system integrators dealing with legacy Alstom protection systems (e.g., for transformers, lines, or busbars), the VCS232 is a key component that enables remote monitoring, control, and integration of the protection system into a wider plant network, thereby enhancing operational visibility and asset management.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

ALSTOM VCS232 590.043158

|

|

Manufacturer

|

Alstom (Legacy, now part of GE Grid/Other)

|

|

Product Family

|

VCS 200 Series (Versatile Control System) or similar modular IED system.

|

|

Product Type

|

Digital I/O and/or Communication Interface Module

|

|

I/O Channels

|

Likely features a bank of configurable digital inputs (for status monitoring) and digital outputs (relay contacts for control/alarms). Count may be 8, 16, or 32 channels.

|

|

Input Type

|

Dry contact (volt-free) or wet contact (e.g., 24/48/110 V DC) sensing, with optical isolation.

|

|

Output Type

|

Form-C relay outputs (changeover contacts) capable of switching control circuits, with specified current/voltage ratings.

|

|

Communication Ports

|

Likely includes one or more serial communication ports (RS-232, RS-485) for protocol conversion.

|

|

Supported Protocols

|

Probable support for standard protocols like Modbus RTU (Slave/Master), IEC 60870-5-103, or proprietary Alstom protocols for communication with a master relay or SCADA.

|

|

Configuration

|

Requires configuration via proprietary software (likely Alstom’s engineering tool) to define I/O mapping, communication parameters, and signal processing (filtering, delays).

|

|

Power Supply

|

Powered from the system backplane or via an external DC supply (e.g., 24/48 V DC).

|

|

Isolation

|

Channel-to-channel and system-to-field isolation for signal integrity and protection.

|

|

Status Indication

|

LEDs for power, communication status, and possibly per-channel I/O status.

|

|

Mounting

|

Designed as a plug-in module for a dedicated chassis or rack within the Alstom system enclosure.

|

|

Operating Temperature

|

Standard industrial range, typically -5°C to +55°C.

|

Key Features and Advantages

ALSTOM VCS232 590.043158 is distinguished by its versatility and role as a system extender. Its primary advantage is providing a configurable I/O and communication interface in a standardized module form factor. This allows engineers to customize the I/O complement of a protection or control cubicle without modifying the central unit. The ability to handle both input (status acquisition) and output (command execution) functions makes it a comprehensive interface solution. Its support for industry-standard serial protocols like Modbus RTU was crucial for integrating legacy Alstom protection relays into modern SCADA and plant monitoring systems without requiring expensive gateways.

Robust design and reliable operation are hallmarks of its industrial application. The module incorporates optical isolation on its I/O channels, which protects the sensitive internal electronics of the main protection device from voltage surges, ground loops, and noise present in the field wiring. This isolation is critical for maintaining the high availability and integrity of protection systems. The use of electromechanical relay outputs (Form-C contacts) provides a robust, well-understood, and electrically isolated means of executing control actions, compatible with a wide range of external devices.

Simplified integration and maintenance are significant benefits. As a standard module within the Alstom VCS family, it ensured compatibility and simplified spare parts management. Its configuration via software allowed for changes to be made without rewiring in many cases. For maintenance personnel, the module’s LED indicators provided immediate visual feedback on its operational status, aiding in rapid troubleshooting. While a legacy component, the VCS232 represented a practical and reliable building block that extended the lifecycle and functionality of Alstom’s protection and control systems, enabling them to meet evolving integration requirements.

Application Areas

The ALSTOM VCS232 590.043158 module was deployed in electrical substation automation, protection, and control systems, primarily in transmission and distribution networks, as well as in large industrial power systems.

It was typically used as an interface unit for:

-

Protection Relays (Bay Control Units): To gather binary statuses (circuit breaker, disconnector, earth switch positions) and to output trip/close commands and alarms from the relay.

-

Transformer and Feeder Protection Panels: For integrating the protection system’s I/O with the station’s control and monitoring network.

-

SCADA/RTU Integration: Acting as a protocol converter, allowing an Alstom protection IED to communicate its data (measurements, statuses, events) to a remote SCADA master station via Modbus or IEC 60870-5-103.

Its applications spanned utility substations, industrial plants (steel, chemicals), and infrastructure projects where Alstom protection equipment was installed. Essentially, it served as the vital «hands and senses» for the «brain» (the main protection/control unit), enabling interaction with the physical switchgear and external control systems.

Related Products

-

Alstom Central Protection/Control Unit (e.g., a specific relay model): The main device to which the VCS232 provides I/O expansion and communication.

-

Alstom VCS Chassis/Power Supply: The hardware platform designed to house and power multiple VCS series modules.

-

Alstom Engineering Configuration Software: The proprietary PC software used to configure the I/O mapping, communication settings, and logic for the VCS232 module.

-

Alstom Communication Modules (for other protocols): Other modules in the VCS family supporting different protocols like Profibus or Ethernet.

-

Termination Boards/Panels: External marshalling cabinets where field wiring is terminated before connection to modules like the VCS232.

-

Modern Protocol Gateways: Contemporary devices that could potentially replace the VCS232 to provide updated communication capabilities (e.g., Modbus TCP, IEC 61850) to legacy systems.

Reviews

There are no reviews yet.