Description

Product Overview

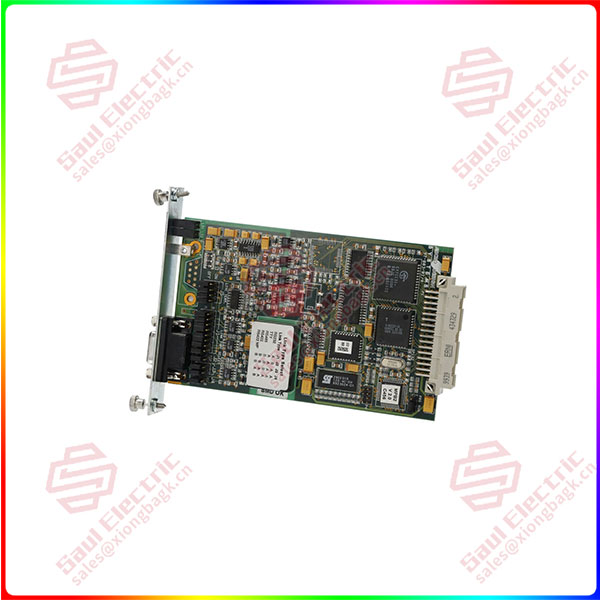

The MICRO MPB1-TP is a highly specialized and compact Microprocessor-Based Protection Relay (or Motor Protection Block), likely designed for the protection of small to medium-sized three-phase AC motors. The «MPB» acronym typically stands for Motor Protection Block, indicating its primary application, and the suffix «TP» may denote a specific feature set, such as a Thermal Protection model with a built-in PTC (Positive Temperature Coefficient) thermistor input for direct winding temperature monitoring. This device is an all-in-one, self-contained unit that provides comprehensive electrical and thermal protection for motors, replacing multiple discrete components like overload relays, undercurrent monitors, and phase failure devices. Its primary function is to continuously monitor motor current, voltage (if equipped), and temperature to safeguard against conditions that can cause premature failure, such as overload, phase loss/unbalance, locked rotor, jam, and excessive winding temperature.

The core value of the MICRO MPB1-TP lies in its integration, precision, and ease of use. It combines advanced electronic protection with a user-friendly interface in a compact, DIN-rail mountable package. By using a microprocessor, it provides much more accurate and adjustable protection characteristics than traditional bimetal overload relays. The inclusion of a dedicated PTC input allows for direct, sensitive thermal protection of the motor windings, offering the highest level of safety against overheating due to poor cooling, high ambient temperature, or frequent starts. For panel builders, OEMs, and maintenance personnel, the MPB1-TP simplifies motor starter design, reduces wiring, provides clear diagnostic indications, and enhances motor reliability, ultimately minimizing downtime and repair costs for critical driven equipment like pumps, fans, and compressors.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

MICRO MPB1-TP

|

|

Manufacturer

|

Likely from a manufacturer specializing in motor protection (e.g., potentially from a brand like ABB (in their MICRO series), Siemens, or a similar OEM).

|

|

Product Type

|

Microprocessor-Based Motor Protection Relay / Motor Protection Block

|

|

Protected Motor Type

|

3-Phase AC Induction Motors

|

|

Current Sensing

|

Built-in or external Current Transformers (CTs). The relay measures true RMS phase currents.

|

|

Protection Functions

|

Typically includes:

|

Key Features and Advantages

MICRO MPB1-TP excels through its integrated thermal management and precise protection. Its standout feature is the direct PTC thermistor input («TP»). This provides the most reliable protection against motor overheating, as it measures the actual winding temperature rather than inferring it from current. It reacts quickly to cooling system failures or blocked ventilation, which an overload curve might miss. The microprocessor-based I²t thermal model accurately simulates motor heating and cooling, accounting for prior starts and operating conditions, preventing nuisance trips during legitimate high-inertia starts while providing optimal running overload protection.

Comprehensive diagnostics and user-friendly operation are central to its design. The device doesn’t just trip; it informs. A display or LEDs indicate the precise cause of a trip (e.g., overload, phase loss, PTC overtemperature), drastically reducing troubleshooting time. It can also provide warning alarms before a trip occurs. The compact, all-in-one design reduces panel space and wiring compared to using separate overload relays, phase monitors, and temperature monitors. Settings are easily adjustable to match the specific motor’s nameplate data and application requirements.

Enhanced motor life and system reliability are the ultimate benefits. By protecting against a wide spectrum of electrical and thermal faults, the MPB1-TP significantly extends motor service life. Its fast and accurate response to locked rotor and short-circuit conditions also protects downstream wiring and contactors. For system designers, it offers a modern, reliable, and space-saving solution that simplifies compliance with motor protection standards. For maintenance teams, it provides clear visibility into motor health, enabling predictive maintenance and ensuring operational continuity of critical processes.

Application Areas

The MICRO MPB1-TP is designed for the protection of three-phase AC induction motors in a wide range of industrial and commercial applications.

Typical applications include:

-

Pumps: Water supply, circulation, and wastewater pumps.

-

Fans and Blowers: HVAC systems, industrial ventilation, and combustion air fans.

-

Compressors: Air compressors and refrigerant compressors.

-

Conveyors and Material Handling Systems.

-

Mixers and Agitators in process industries.

It is particularly valuable for motors that are critical to process continuity, operate in harsh thermal environments, or are difficult to access for maintenance. The PTC input feature makes it ideal for motors where winding temperature is a major concern, such as tightly sized motors, high-inertia loads, or those in enclosed spaces. Essentially, it is a superior choice for any motor starter application where enhanced protection, diagnostics, and reliability beyond a simple thermal overload relay are desired.

Related Products

-

Motor Contactors/Starters: The switching devices controlled by the outputs of the MPB1-TP.

-

Current Transformers (CTs): If the relay uses external CTs for current sensing.

-

PTC Thermistor Sensors: The temperature sensors installed in the motor windings that connect to the «TP» input.

-

Control Power Transformers/Switched Mode Power Supplies: To provide the control voltage for the relay.

-

Push Buttons/Selector Switches: For providing start/stop/reset signals to the relay’s digital inputs.

-

Communication Gateways: If integration to a higher-level PLC/SCADA is required and the relay has a communication option.

Reviews

There are no reviews yet.