Description

Product Overview

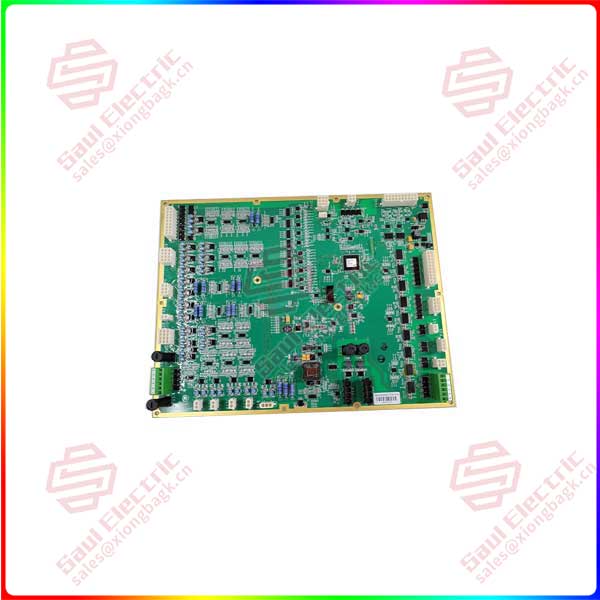

The GE IS200WETAH1AEC is a specialized I/O Communication Interface Module from the General Electric (GE) Mark VI Speedtronic™ gas/steam turbine control system. The designation «WETA» strongly suggests it functions as a WEdgTrip Adapter or a specialized interface module for critical trip/control functions, potentially associated with the turbine’s Wedgemount™ flame detection system or other primary protection devices. This module’s primary function is to serve as a high-integrity, deterministic interface between the Mark VI controller and critical external safety or protection devices, such as flame scanners and the associated fuel trip solenoids. It likely acquires signals from flame detectors (confirming burner flame presence/absence) and outputs permissive or trip commands to the fuel safety shut-off valves, forming a vital part of the turbine’s Burner Management System (BMS) or Flame Detection and Protection logic.

The value of the GE IS200WETAH1AEC lies in its critical role in turbine safety, reliability, and deterministic response. It provides a robust, isolated, and fast communication path for signals that are essential for preventing hazardous conditions like furnace explosions (in steam turbines/HRSGs) or continued fuel flow without flame. The module ensures that flame status is read reliably and that trip commands are executed with minimal latency. Its design likely incorporates diagnostics and redundant communication paths to meet the high availability and safety integrity requirements of protection systems. For control engineers and maintenance technicians, the proper operation of the WETA module is non-negotiable for safe turbine start-up, operation, and shutdown. It acts as a trusted, high-performance interface that translates critical field conditions into actionable data for the Mark VI’s protection logic, directly safeguarding personnel, equipment, and the asset itself.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

GE IS200WETAH1AEC

|

|

Manufacturer

|

General Electric (GE)

|

|

System Platform

|

Mark VI Speedtronic™ Turbine Control System

|

|

Product Type

|

Critical I/O Interface Module (for Flame Detection/Protection)

|

|

Primary Function

|

Interfaces with flame scanners and fuel trip solenoids; part of the Burner Management/Flame Safeguard system.

|

|

Input Channels

|

Accepts signals from multiple flame scanners/detectors (likely UV, IR, or visible light sensors). Inputs are probably conditioned (amplified, filtered) and digitized.

|

|

Output Channels

|

Provides outputs to drive Fuel Trip Solenoids (typically high-integrity relay outputs or solid-state drives) to cut off fuel on a loss of flame or other trip condition.

|

|

Communication Interface

|

Connects to the Mark VI controller via the VME/PCI backplane. May use a dedicated, high-speed, and deterministic protocol for this critical data.

|

|

Diagnostics

|

Extensive self-diagnostics and field device monitoring: checks for flame scanner failure, loss of signal, output circuit health, and module internal faults.

|

|

Response Time

|

Extremely fast response time is critical for flame safety. The module is designed for minimal latency in both input acquisition and output execution.

|

|

Isolation

|

High-grade isolation between field-side connections (flame scanners, solenoids) and the system electronics to prevent noise interference and protect the controller.

|

|

Redundancy Support

|

Likely designed to be used in redundant configurations (e.g., 2-out-of-2 or 2-out-of-3 voting) to meet safety requirements.

|

|

Configuration

|

Configured using GE’s ToolboxST software. Parameters may include flame signal thresholds, validation times, output pulse durations, and voting logic.

|

|

Power Supply

|

Powered from the Mark VI rack backplane, with possible redundant inputs.

|

|

Status Indication

|

Front-panel LEDs for power, fault, channel status (flame ON/OFF), and output state.

|

|

Mounting

|

Installs in a designated slot within the Mark VI control rack.

|

|

Operating Temperature

|

0°C to 60°C (for control cabinet environment).

|

Key Features and Advantages

GE IS200WETAH1AEC is distinguished by its application-specific design for high-integrity flame safety. Its foremost advantage is providing a dedicated, optimized interface for the most critical loop in a turbine’s protection system: flame detection and fuel trip. The circuitry and firmware are tailored to handle the specific signal characteristics of flame scanners and the driving requirements of trip solenoids, ensuring reliable operation. The module’s extremely fast response time is crucial to prevent dangerous accumulation of unburned fuel.

Comprehensive diagnostics and safety-focused architecture are engineered into its core. Beyond simply passing signals, the module actively monitors the health of the connected flame scanners, detecting faults that could lead to a spurious trip or, more dangerously, a failure to trip. Diagnostic information is communicated to the Mark VI controller for immediate operator awareness. The design likely supports redundant or voting configurations, aligning with industry best practices for burner management systems (BMS) to achieve high safety availability and prevent nuisance trips.

Seamless integration and reliability within the Mark VI ecosystem are key benefits. As a genuine GE component, it guarantees compatibility and performance with the rest of the control system. Its configuration within ToolboxST provides a unified engineering environment. The module’s robust construction ensures it meets the 24/7 operational demands of a power plant. For system designers, the WETAH1AEC provides a certified, reliable, and maintainable solution for implementing a vital safety function, reducing engineering risk and complexity. Its proper function is a cornerstone of the turbine’s operating permit and overall plant safety.

Application Areas

The GE IS200WETAH1AEC module is a critical component within the Burner Management System (BMS) or flame safeguard system of GE gas turbines and heat recovery steam generators (HRSGs).

Its specific application is:

-

Gas Turbine Combustion Monitoring: Interfacing with multiple flame scanners around the combustor to monitor flame presence during start-up and load operation.

-

HRSG (Duct Burner) Protection: Monitoring flames in supplementary-fired heat recovery steam generators.

-

Standalone Burner Systems: For other fired equipment controlled by a Mark VI system.

Upon detection of a loss of flame, this module is responsible for initiating a rapid fuel trip to prevent a furnace explosion. Essentially, it is deployed wherever a GE Mark VI system is used to manage a combustion process requiring high-integrity flame detection and fuel safety shutoff, which is a universal requirement in fossil-fueled power generation.

Related Products

-

Flame Scanners (UV/IR detectors): The field devices that provide the flame signal input to the WETA module.

-

Fuel Trip Solenoid Valves: The final control elements that shut off fuel, driven by the WETA’s output.

-

GE Mark VI Controller: Executes the BMS logic that uses data from and sends commands to the WETA module.

-

Redundant WETA Modules: For systems requiring 2-out-of-2 voting for increased safety/availability.

-

GE ToolboxST Software: For configuration, calibration, and monitoring of the flame detection system.

-

Burner Management Cabinet: The enclosure housing the WETA modules and associated terminals.

Reviews

There are no reviews yet.