Description

Product Overview

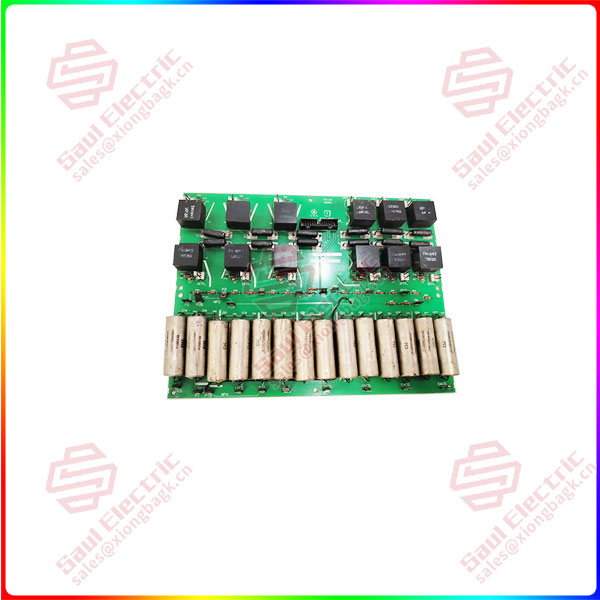

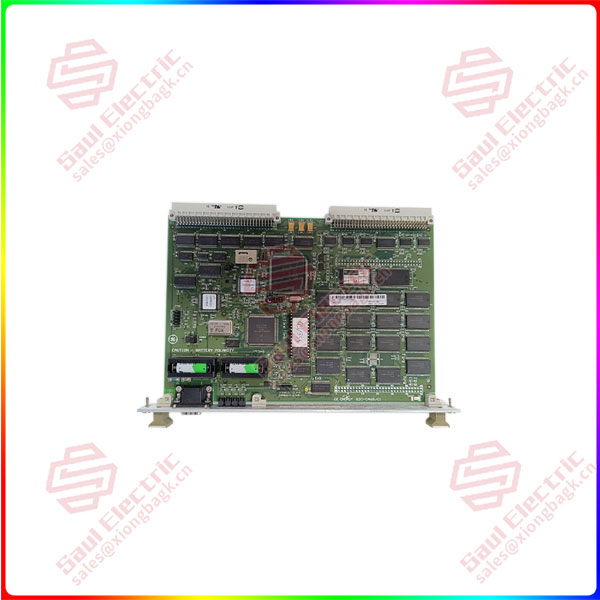

The GE DS200PCCAG1ACB is a critical Power Conversion and Control Module from the General Electric (GE) Mark VI Speedtronic™ gas/steam turbine control system, part of the renowned Speedtronic™ series. The designation «PCCA» likely indicates a Power Conversion and Control Assembly, suggesting it is a specialized power supply or signal conditioning module. This module is designed to perform a vital interface function within the Mark VI cabinet, possibly converting plant AC or DC power into the specific, regulated, and isolated DC voltages required by other sensitive control boards (such as processor modules, I/O packs) or serving as a dedicated power source for a particular subsystem (e.g., solenoid valves, transducers). The suffix

G1ACBdenotes a specific hardware revision, input voltage range, output configuration, and certification details.The value of the GE DS200PCCAG1ACB lies in its specialized power management, reliability, and integration within the Mark VI’s distributed architecture. In complex turbine control systems, different modules and field devices often require different voltage levels and power characteristics. The PCCA module is engineered to meet these specific demands reliably, providing clean, stable, and often isolated power rails. It may incorporate diagnostic features to monitor its output health and communicate status back to the main controller. For the turbine control system’s overall stability, having dedicated, robust power conversion modules like the PCCAG1ACB is essential to prevent electrical noise, transients, or failures in one part of the system from affecting others. It acts as a reliable «power domain manager» within the control cabinet, ensuring that critical control and I/O circuits receive uninterrupted and high-integrity power, which is fundamental to the turbine’s continuous, fault-free operation.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

GE DS200PCCAG1ACB

|

|

Manufacturer

|

General Electric (GE)

|

|

System Platform

|

Mark VI Speedtronic™ Turbine Control System

|

|

Product Type

|

Power Conversion / Control Assembly Module

|

|

Primary Function

|

Converts input power to regulated, isolated DC outputs for system components; may also include control logic or signal conditioning.

|

|

Input Power

|

Likely accepts a wide-range AC or DC input, such as 85-264 VAC, 47-63 Hz, and/or 110-250 VDC, as specified by the

G1ACBsuffix. |

|

Output Voltages

|

Provides one or more isolated DC voltage rails. Common outputs in Mark VI systems include +5V (logic), ±15V (analog), +24V (for relays, solenoids), or other application-specific voltages.

|

|

Output Power Rating

|

Sufficient to power a group of modules or a specific subsystem. Rating is defined by the model variant.

|

|

Regulation & Ripple

|

Tight voltage regulation and low output ripple/noise to ensure stable operation of sensitive electronics.

|

|

Protections

|

Includes standard protections: input undervoltage/overvoltage lockout, output overvoltage, overcurrent, short circuit, and overtemperature protection.

|

|

Isolation

|

Provides galvanic isolation between input and output, and possibly between multiple outputs, to prevent ground loops and noise coupling.

|

|

Diagnostics & Monitoring

|

May include status indicators (LEDs) for power good, fault conditions, and possibly communication of health status to the Mark VI controller via a digital signal or backplane communication.

|

|

Cooling

|

Convection or forced air cooling, depending on power dissipation.

|

|

Mounting

|

Designed as a plug-in module for a Mark VI rack or chassis.

|

|

Connection

|

Interfaces via the Mark VI backplane for power distribution and potentially for control signals.

|

|

Operating Temperature

|

0°C to 60°C (standard for control cabinet environments).

|

|

Certifications

|

Designed to comply with cULus, CE, and other relevant industrial safety and EMC standards.

|

Key Features and Advantages

GE DS200PCCAG1ACB excels as a dedicated, reliable power source for critical control functions. Its primary advantage is providing clean, regulated, and isolated power specifically tailored for the needs of the modules it supports. This dedicated design often offers better performance and reliability than a generic, centralized power supply feeding a large backplane. The inclusion of comprehensive protections safeguards both the power supply itself and the sensitive load components from damage due to electrical faults.

Enhanced system integrity and diagnostic capability are engineered into its operation. The isolation provided helps in segmenting the electrical noise within the cabinet, improving the signal integrity of analog and digital circuits. If equipped with monitoring features, it can provide early warning of impending failure (e.g., reporting a degrading output voltage), enabling proactive maintenance. The module’s design ensures high availability; in systems with redundant power paths, a PCCA module failure might only affect a non-critical or redundant subsystem, minimizing overall system impact.

Seamless integration and serviceability within the Mark VI ecosystem are key benefits. As a genuine Mark VI component, it guarantees mechanical and electrical compatibility with the rack and other modules. Its modular, plug-in design facilitates easy testing, replacement, and potential upgrades. For system designers, using such specialized modules simplifies the power architecture design. For maintenance technicians, having a clearly defined function (power conversion for a specific group) aids in troubleshooting—if all modules in a section lose power, the PCCA supplying them becomes the primary suspect. In summary, the DS200PCCAG1ACB provides a trusted, application-optimized power solution that contributes to the overall robustness and maintainability of the Mark VI control system.

Application Areas

The GE DS200PCCAG1ACB is deployed within GE Mark VI turbine control cabinets, where specialized or localized power conversion is required.

Its application is specific to the internal power distribution of the Mark VI system. It might be used to:

-

Power a cluster of I/O modules in a remote or expansion rack.

-

Supply dedicated power to critical subsystems such as the turbine protection solenoid valves, servo controllers, or communication interfaces.

-

Provide isolated analog power for high-precision measurement circuits.

Essentially, it is found wherever within a Mark VI control system there is a need for a dedicated, reliable, and conditioned power source that is separate from the main system backplane power, typically to enhance performance, reliability, or to meet specific voltage/current requirements of a group of devices.

Related Products

-

GE Mark VI Main Controller & I/O Modules: The primary loads powered by the PCCA module.

-

GE Mark VI Main System Power Supplies (e.g., BPPB): Which provide the primary backplane power; the PCCA may derive its input from these or directly from the plant supply.

-

Mark VI Backplane/Chassis: The infrastructure that houses the PCCA and other modules.

-

Field Devices (Solenoids, Transducers): Which may be powered by the outputs of the PCCA.

-

GE ToolboxST Software: While primarily for controller logic, may provide system-level health monitoring that includes status of power-related modules.

Reviews

There are no reviews yet.