Description

Product Overview

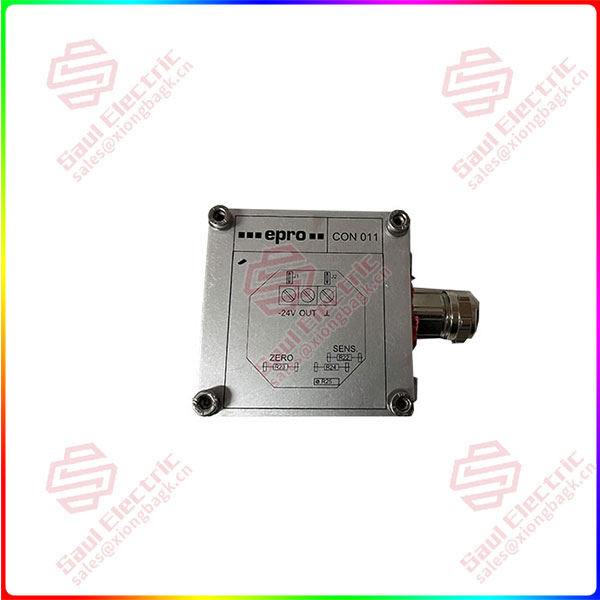

The EPRO PR6424/013-130+CON021 is a complete, high-precision Eddy Current Proximity Transducer System, configured for specific application requirements within the EPRO (Baker Hughes Bently Nevada) condition monitoring portfolio. This part number represents a kit or assembly comprising a standard PR6424/013-130 transducer system (probe, extension cable, proximitor) plus an additional component designated as CON021. The PR6424 is the core 8mm eddy current system for measuring shaft relative vibration and position. The suffix

/013-130specifies details like probe length, thread, cable length, and proximitor type. The +CON021 likely denotes a special connection accessory, such as a terminal block adapter, a specific connector (e.g., for direct connection to a particular monitor like an EPRO MMS 6000 series), a calibration resistor, or a mounting bracket kit. Its primary function remains the non-contact measurement of shaft vibration, position (gap), and speed (Keyphasor), with the CON021 accessory ensuring proper, secure, and often simplified electrical or mechanical interface to the monitoring system.The value of this specific configuration (EPRO PR6424/013-130+CON021) lies in its application-ready completeness and integration ease. By bundling the standard transducer with a necessary interface accessory, it eliminates guesswork during installation, ensures compatibility, and reduces the risk of connection errors. This is particularly important for critical machinery protection systems where a faulty connection can lead to signal loss or measurement inaccuracies, potentially masking a dangerous condition. For maintenance engineers and system integrators, procuring this kit means receiving all the physical components needed to implement a specific measurement point according to a predefined design, streamlining the installation process and enhancing the overall reliability of the monitoring channel. It represents a «solution in a box» for a standardized measurement application.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

EPRO PR6424/013-130+CON021

|

|

Manufacturer

|

EPRO (Baker Hughes Bently Nevada)

|

|

Product Type

|

Eddy Current Proximity Transducer System with Interface Accessory

|

|

Core System

|

PR6424/013-130: Includes:

|

Key Features and Advantages

EPRO PR6424/013-130+CON021 excels through its pre-configured, application-specific design. The primary advantage is receiving a fully compatible, ready-to-install measurement chain. The inclusion of the CON021 accessory ensures that the electrical interface between the proximitor and the monitoring system is handled correctly, whether it involves a specific plug, terminal assignments, or integrated calibration. This eliminates the need to source separate, potentially incompatible connectors and reduces wiring errors during panel assembly.

Enhanced reliability and time savings are direct benefits. By providing a matched set, the kit guarantees that all components are designed to work together, optimizing signal integrity. For the installer, it saves time and effort in procuring and assembling disparate parts. The reliability of the connection is as critical as the sensor itself; a poor connection can cause intermittent signals that are difficult to diagnose. A factory-supplied accessory like CON021 is engineered for a secure, vibration-resistant fit.

Simplified documentation and inventory management are practical advantages. Using a single kit part number for a complete measurement point simplifies the bill of materials (BOM), procurement, and inventory tracking. It also makes system documentation and as-built drawings clearer. For maintenance, having a documented kit part number ensures that the exact replacement can be ordered, preserving the original design’s integrity. In summary, this configuration transforms a standard sensor system into a tailored, drop-in solution that enhances the overall quality, reliability, and maintainability of the machinery monitoring installation.

Application Areas

The application areas for the EPRO PR6424/013-130+CON021 are identical to the standard PR6424 system, but with the added context that it is configured for integration into a specific monitoring system or cabinet design.

It is used for monitoring shaft radial vibration, axial position, and speed on:

-

Gas and Steam Turbines

-

Centrifugal and Axial Compressors

-

Large Pumps, Fans, and Motors

-

Generators and Gearboxes

The +CON021 suffix implies it is intended for installations where the monitoring system (e.g., an EPRO MMS 6000 rack, a Bently Nevada 3500 system, or a specific OEM’s panel) requires a particular connection method. It is commonly found in new projects or retrofit upgrades where the system design specifies standardized connection kits to ensure consistency and ease of installation across hundreds of measurement points in a large plant.

Related Products

-

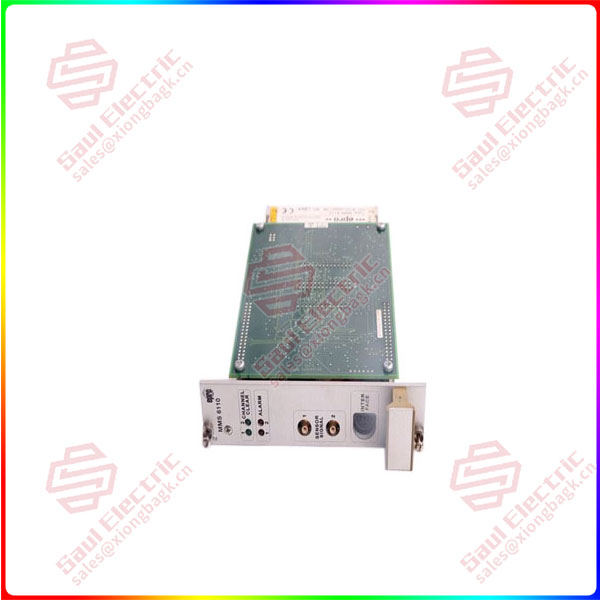

EPRO MMS 6000/MMS 7000 Monitor Racks: The likely destination system for the transducer signals via the CON021 interface.

-

Bently Nevada 3500/42M Monitor: Another common monitor compatible with PR6424 signals (may use a different connector kit).

-

EPRO TK-3 Transducer Tester: For field verification and troubleshooting of the installed PR6424 system.

-

Mounting Hardware (Probe Holders, Brackets): For physically installing the probe on the machinery.

-

Spare Probes and Extension Cables: Sold separately under their own part numbers (e.g., PR6424/000-xxx).

-

Other CONxxx Kits: Different interface kits for other monitor types or applications.

Reviews

There are no reviews yet.