Description

Product Overview

The Tricon 3700A is a triple modular redundant (TMR) analog input module designed for the Tricon v9, v10, and v11 series Safety Instrumented Systems (SIS), manufactured by Invensys (now part of Schneider Electric). It is a critical component in the Triconex I/O subsystem, responsible for safely and reliably acquiring analog process signals—such as 4-20 mA current, 0-10V voltage, RTD, or thermocouple inputs—from field transmitters and sensors, and converting them into high-resolution digital values for the Tricon Main Processor. The 3700A module provides a high-integrity interface for continuous process variables that are essential for safety-related monitoring and control, such as pressure, temperature, flow, and level.

The core value of the Tricon 3700A lies in its high-accuracy, fault-tolerant analog signal acquisition within a TMR architecture. Each analog input channel is processed by three completely independent circuits, and the results are voted upon to ensure accuracy and reliability. This design is crucial for Safety Instrumented Systems (SIS) where decisions to initiate a safety shutdown (e.g., high pressure, high temperature) are based on the integrity of these analog signals. For engineers and operators in industries like oil and gas, petrochemicals, and power generation, the 3700A is the trusted component for bringing critical process variables into a SIL 3 (IEC 61508/61511) certified safety system with the high availability and diagnostic coverage required to prevent dangerous failures.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

Tricon 3700A

|

|

Manufacturer

|

Invensys Triconex (now Schneider Electric)

|

|

Product Family

|

Tricon TMR Analog Input Module

|

|

Primary Function

|

8-channel, Triple Modular Redundant (TMR) Analog Input Module (configurable per channel for various signal types)

|

Electrical Characteristics

-

Input Channels: 8 channels, individually configurable per channel via TriStation software.

-

Input Types (Configurable per Channel):

-

Current Input: 4-20 mA (can also accept 0-20 mA). High impedance input (~250Ω).

-

Voltage Input: 1-5V DC, 0-5V DC, 0-10V DC.

-

Temperature Input (RTD): 2-wire, 3-wire, or 4-wire Pt100 (most common), also supports Pt1000, Cu10, Ni120. Provides excitation current and measures resistance.

-

Temperature Input (Thermocouple): Supports types J, K, T, E, R, S, B, N. Includes internal cold junction compensation (CJC).

-

-

Resolution: 16-bit analog-to-digital (A/D) conversion per channel, providing high resolution for accurate measurement.

-

Accuracy: Typically ±0.1% of full scale or better for current/voltage inputs. Accuracy for RTD/TC depends on sensor type and linearization.

-

Sampling Rate: Configurable update rate per channel, balancing speed and noise filtering.

-

Input Impedance: High impedance for voltage inputs (>1 MΩ). Current inputs present a low impedance (~250Ω) loop load.

-

Isolation: Channel-to-channel isolation and field-to-system isolation (typically 1500V AC) to prevent ground loops and noise interference.

-

Common Mode Rejection Ratio (CMRR): High CMRR (>120 dB) to reject electrical noise.Safety & Architecture

-

Architecture: TMR (Triple Modular Redundant) per channel. Each field input is connected to three completely isolated input circuits (A, B, C) with separate A/D converters. The three readings are voted upon within the Main Processor.

-

Diagnostics: Extensive onboard diagnostics including:

-

Open Circuit Detection: For 4-20 mA loops (detects current < ~3.6 mA).

-

Sensor Burnout Detection: For RTD/TC inputs (detects open sensor).

-

Over-range/Under-range Detection.

-

Internal Circuit Fault Detection (mismatch between the three A/D readings, A/D converter fault).

-

-

Fusing: Each channel or group of channels typically has internal fusing for overcurrent protection.Mechanical & Integration

-

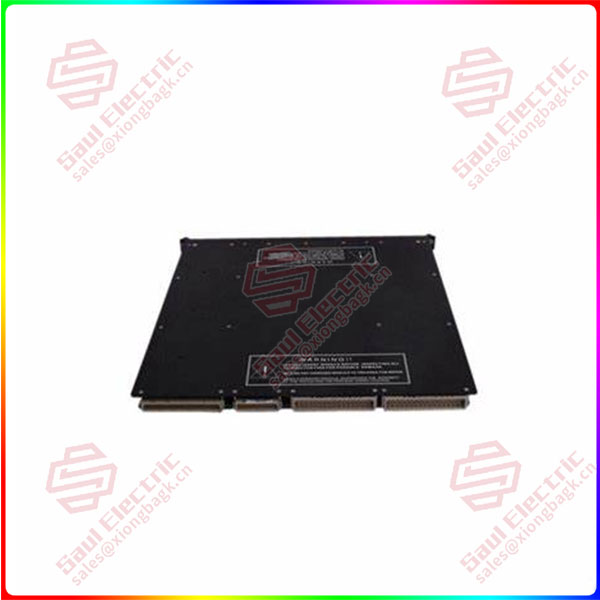

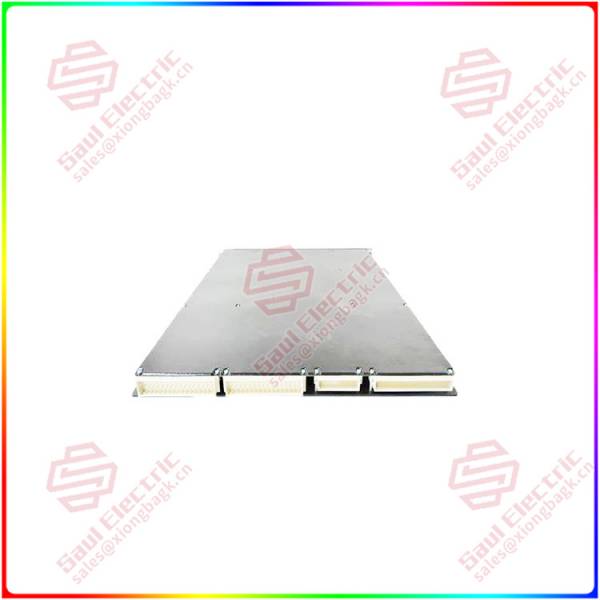

Form Factor: A hot-swappable module designed for the Tricon High Density (HD) I/O Terminator Baseplate (e.g., 9563-610, 9563-810 series).

-

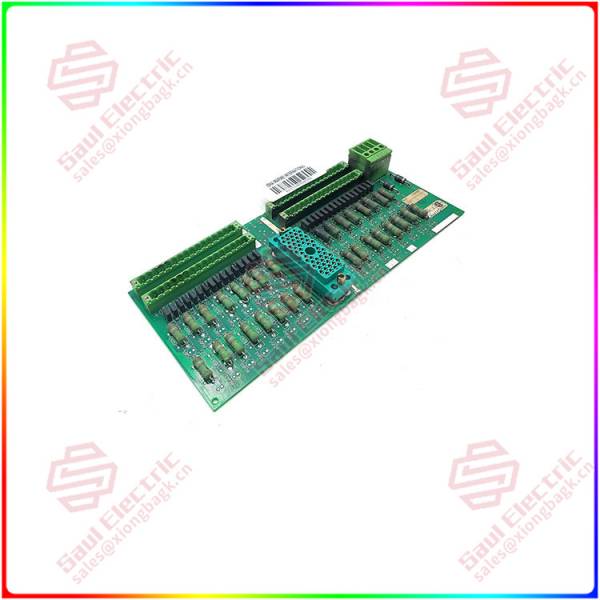

Termination: Field wiring connects to a removable terminal block on the associated terminator baseplate. RTD/TC modules may have specific terminal blocks for sensor wiring configurations (2/3/4 wire).

-

LED Indicators: Module health LEDs (Power OK, Fault) and often a channel activity/status LED. Detailed per-channel status is available via software.

-

Configuration: Fully configurable via Triconex TriStation 1131 software (input type, range, engineering units, filtering, alarm setpoints).Environmental & Compliance

-

Operating Temperature: 0 to 60°C (32 to 140°F)

-

Certifications: Designed and certified for use in SIL 3 (IEC 61508) safety systems. Suitable for harsh industrial environments.

Key Features and Advantages

High Accuracy and Reliability with TMR Design: The triple-redundant A/D conversion and voting ensure that a single fault in any one channel’s measurement circuit will be detected and masked, providing continuous, accurate data to the safety logic solver. This is essential for maintaining process safety availability.

Flexible Multi-Signal Support: The ability to mix and match different signal types (mA, V, RTD, TC) on a single 8-channel module provides tremendous design flexibility and reduces spare part inventory. A single module type can handle most common analog sensor inputs in a safety system.

Comprehensive Diagnostics for High Diagnostic Coverage: The module’s ability to diagnose field wiring problems (open circuit, sensor burnout) and internal hardware faults provides a high Safe Failure Fraction (SFF). This allows the system to identify dangerous undetected failures and take appropriate action, which is a cornerstone of SIL 3 certification for analog inputs.

Hot-Swap Capability for High Availability: The module can be replaced online without shutting down the Tricon controller or the process it protects. This is critical for maintaining the high availability expected of modern safety systems during maintenance operations.

Application Areas

The Tricon 3700A is used in safety-critical shutdown systems (ESD/PSD/F&G/BMS) to monitor continuous process variables that are part of safety instrumented functions (SIFs).

-

Emergency Shutdown (ESD) Systems: Monitoring pressure transmitters (vessel pressure), level transmitters (tank overfill), and flow transmitters (high/low flow) to initiate shutdowns.

-

Fire & Gas (F&G) Systems: Reading analog signals from toxic/combustible gas detectors (4-20 mA output) and smoke/heat detector analog values.

-

Burner Management Systems (BMS): Monitoring furnace temperatures (via thermocouples), fuel gas pressure, and combustion air flow.

-

Turbomachinery Control (TMC): Acquiring critical signals like bearing temperatures (via RTDs), case vibrations (4-20 mA), and speed.

-

High-Integrity Pressure Protection Systems (HIPPS): Measuring pipeline pressure with high-reliability transmitters to trigger fast-acting shutdown valves.

Related Products

-

Terminator Baseplate: The HD I/O Terminator Baseplate (e.g., 9563-610 for analog I/O) is required. It provides the field wiring terminals, signal conditioning, and isolation. The 3700A module plugs into this baseplate.

-

Tricon Chassis & Main Processor: Such as the Tricon Chassis 3008/3009/3510/3511 and the corresponding Main Processor (MP), which houses and communicates with the I/O modules.

-

Field Sensors: The analog signal sources: pressure/level/flow transmitters (4-20 mA), RTD temperature sensors (Pt100), thermocouples (Type J, K, etc.).

-

Programming & Configuration Software: Triconex TriStation 1131 is used to configure every aspect of the module: input type, range, engineering units, filter time, alarm trips, and diagnostic responses.

-

Other I/O Modules: In the same family: 3604E (24V DC DI), 3504E (24V DC DO), 3805E (Comm), and other analog modules like the 3703A (isolated analog output).

Reviews

There are no reviews yet.