Description

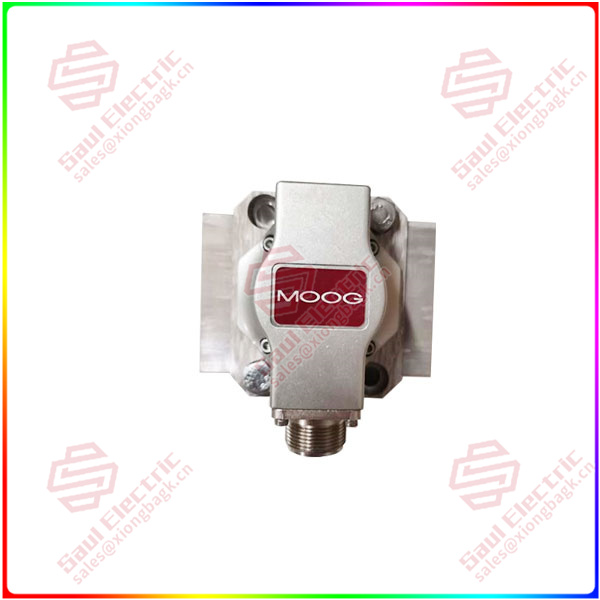

MOOG G771K202A — Technical Overview

Product: G771K202A, Servo Control Module / Electronic Drive Unit

Manufacturer: Moog Inc.

Primary Application: A high-performance servo controller/amplifier module designed for precise closed-loop control of electro-hydraulic servo valves (EHSV), electro-mechanical actuators (EMA), or other proportional devices in demanding motion control applications within aerospace, defense, and industrial automation.

1. Core Overview & Positioning

The Moog G771K202A is a specialized electronic control module from Moog’s G771 series of servo controllers. It functions as the intelligent power and control interface between a motion controller (host computer/PLC) and a high-performance servo actuator. Its primary role is to execute precise closed-loop control algorithms, driving an actuator to accurately follow a position, velocity, or force command.

Key Philosophy: It provides the necessary signal conditioning, power amplification, and high-speed control logic to transform a low-level command signal into a precise, high-power output capable of driving demanding servo loads with exceptional dynamic response and stability.

2. Key Features & Functions

-

Closed-Loop Servo Control: Implements advanced control algorithms (typically PID with velocity/acceleration feedforward, notch filters, and advanced compensation) to minimize the error between the command signal and the actual feedback from a position/velocity transducer (e.g., LVDT, RVDT, resolver).

-

High-Current Output Stage: Contains a power amplifier designed to deliver the specific current (often in the range of ±100mA to ±2A) required to drive the inductive coil of a high-performance Moog servo valve or the windings of a torque motor.

-

Flexible Input Configuration:

-

Command Input: Accepts an analog command signal (typically ±10V DC differential).

-

Feedback Input: Primarily designed for AC-excited LVDT (Linear Variable Differential Transformer) or RVDT (Rotary Variable Differential Transformer) feedback, providing the excitation signal and measuring the return amplitude/phase to determine actuator position.

-

-

Comprehensive Diagnostics & Protection:

-

Continuous monitoring for coil faults (open circuit, short circuit).

-

Feedback sensor health monitoring (signal level, frequency).

-

Overtemperature protection for the output stage.

-

Command-Feedback discrepancy (excessive following error) detection.

-

-

Field Configurable: Control loop parameters (Proportional, Integral, Derivative gains, feedforward gains, filter frequencies, current limits) are adjustable, typically via Moog configuration software or a programming pendant, allowing the drive to be tuned for the specific actuator and load dynamics.

-

Robust Design: Engineered for reliable operation in harsh environments, with protection against vibration, shock, and wide temperature ranges. The PCB is often conformally coated.

3. Model Number Analysis & Specifications

Inferred Technical Specifications (Must be verified with official datasheet):

-

Output Drive: Current output, likely in the range suitable for Moog G631, G761 series servo valves.

-

Command Input: ±10V DC differential, high impedance.

-

Feedback: AC LVDT/RVDT input with programmable excitation.

-

Power Supply: Requires external DC power supplies, typically ±15V DC for control logic and a higher voltage (e.g., +24V to +80V DC) for the output stage.

-

Communication: May include a service port (RS-232/422/485) for configuration and monitoring via Moog software tools.

-

Form Factor: Typically a printed circuit board (PCB) assembly designed for chassis or enclosure mounting.

4. System Integration & Application

-

Role in Control Chain: It acts as the dedicated servo drive in a hierarchical system:

-

Host Motion Controller calculates trajectory → sends Analog Command to G771K202A.

-

G771K202A processes command and LVDT feedback → outputs Drive Current to Servo Valve.

-

Servo Valve controls hydraulic flow → moves Actuator/Piston.

-

LVDT on actuator provides Position Feedback to G771K202A, closing the loop.

-

-

Configuration & Tuning: Essential for performance. Using Moog software (e.g., Moog Servo Driver Suite or a dedicated programmer), an engineer must:

-

Set LVDT excitation parameters.

-

Perform LVDT null/span calibration.

-

Tune the PID and feedforward gains to achieve the desired step response (fast, stable, without overshoot).

-

-

Integration: Mounted in a system control cabinet, interfacing with a higher-level multi-axis controller (like a Moog MCU-2000) or a custom automation system.

5. Typical Applications

-

Industrial Automation & Test:

-

Servohydraulic Test Systems: Driving actuators in materials testing machines (fatigue, structural testing).

-

Simulator Motion Bases: Controlling hydraulic actuators for flight, driving, or marine simulators.

-

Precision Industrial Machinery: For controlling rollers, knives, or presses requiring ultra-precise, high-force motion.

-

-

Aerospace & Defense:

-

Flight Control Actuation: Research and development test rigs for control surfaces.

-

Fuel Control Systems: For gas turbine engine test stands.

-

Specialized Vehicle Control: Turret stabilization, weapon pointing systems.

-

Reviews

There are no reviews yet.