Description

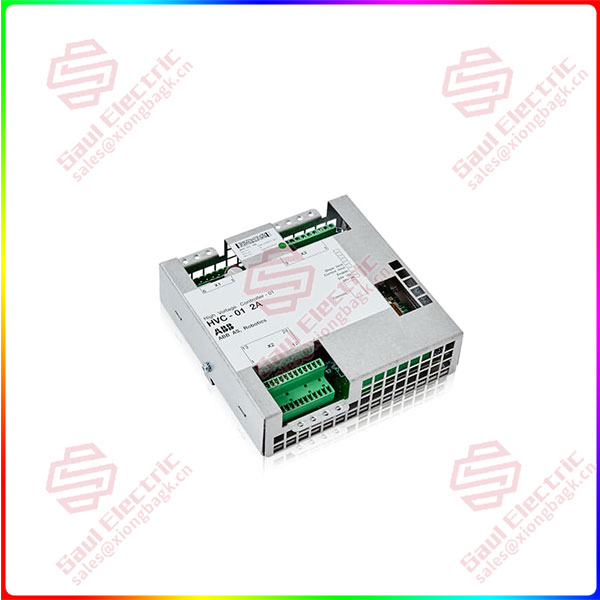

ABB NAIO-03F (3AFE6466928) — Digital Input/Output Module

Product: NAIO-03F, Digital Input/Output Module

Manufacturer: ABB

Order Code: 3AFE6466928

Primary Application: A high-performance, flexible digital input/output (I/O) module for ABB’s AC 800M High Integrity or AC 800M Safety controllers, designed for demanding applications in process automation, particularly where fast response times, high channel density, and flexible configuration are required.

1. Core Overview & Positioning

The ABB NAIO-03F is a member of the S800 I/O family, specifically designed for the high-performance and safety-rated AC 800M HI and safety controller platforms. The «NAIO» designation stands for New generation Analog/Input-Output, highlighting its advanced architecture.

Key Philosophy: It provides a combination of high-speed digital inputs (suitable for fast counting, event detection) and configurable digital outputs in a single module. Its primary advantage is flexibility and speed, making it ideal for interlocking, sequencing, and fast control tasks in complex process plants.

2. Key Features & Functions

-

Mixed I/O on One Module: Combines dedicated inputs and outputs, optimizing slot usage in the I/O rack.

-

High-Speed Inputs (HSI): A subset of the inputs are designed as High-Speed Inputs, capable of detecting very short pulses (with typical response times in the microsecond range). This is essential for applications like:

-

Turbine Speed Sensing (from magnetic pickups).

-

Flow Meter Pulsing (frequency counting).

-

Fast Event Sequencing.

-

-

Flexible Output Configuration: The digital outputs are software-configurable to operate in different modes, such as standard on/off control or pulsed output.

-

Diagnostics & Safety: Includes comprehensive channel-level and module-level diagnostics. When used with an AC 800M Safety controller, it can be part of a Safety Instrumented System (SIS) meeting SIL 3 requirements, as it supports test pulse patterns for output verification.

-

Hot-Swappable: Designed for online insertion and removal in a live system (with proper redundancy), maximizing plant availability.

-

Communication: Integrates seamlessly via the S800 I/O bus to the AC 800M controller. The exact I/O image and update times are configured in the control project.

3. Model Number & Order Code Analysis

Common Technical Specifications (Inferred for NAIO-03F):

-

Channel Configuration: Typically provides 16 digital inputs and 8 digital outputs in a single module. A certain number of the inputs (e.g., 8) are designated as High-Speed Inputs (HSI).

-

Input Types:

-

Standard DI: 24 V DC, sinking/sourcing.

-

High-Speed DI: 24 V DC, capable of high-frequency signals (e.g., up to 10 kHz).

-

-

Output Types: Digital Outputs, typically 24 V DC, 0.5A, with short-circuit protection. Configurable as standard DO or pulse output.

-

Isolation: Channel-to-channel and channel-to-system isolation.

-

Mounting: A single-width module for the S800 I/O rack (e.g., mounts on a TU810 or TU830 base unit).

-

Power Supply: Powered from the S800 I/O rack’s backplane.

4. System Integration

-

Controller Compatibility: Designed for use with ABB AC 800M High Integrity (PM856, PM860, etc.) and AC 800M Safety (SM810, etc.) controllers.

-

Physical Installation: Installed in an S800 I/O station, which connects to the controller via a CI854 (PROFIBUS) or CI871 (Ethernet) communication interface, or directly via the S800 I/O link.

-

Engineering: Fully configured within ABB’s Control Builder engineering tool (part of the 800xA or Compact Product Suite). Here, the engineer:

-

Defines the module type and position in the hardware configuration.

-

Configures the function of each channel (e.g., which inputs are high-speed, output pulse width).

-

Maps physical I/O points to variables in the application code.

-

-

Role: Acts as the primary interface for fast digital signals in safety or high-availability loops, such as permissive logic, turbine trip signals, or high-speed counting.

5. Typical Applications

-

Turbomachinery Control (TMC): Reading speed probe (MPU) signals for overspeed protection and governor control.

-

Fire & Gas (F&G) Systems: Fast detection of flame or gas detector trips and activation of suppression systems.

-

Emergency Shutdown (ESD) Systems: Processing critical trip signals and initiating valve closures.

-

Burner Management Systems (BMS): Monitoring flame scanner status and controlling igniters/fuel valves.

-

Sequencing & Interlocking: In compressor stations or complex chemical processes.

Reviews

There are no reviews yet.