Description

Product Overview

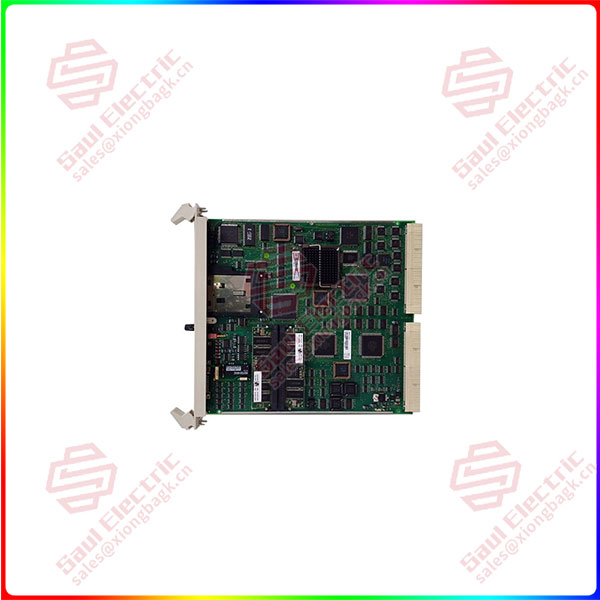

The ABB PM511V16 3BSE011181R1 is a high-performance Central Processing Unit (CPU) or Controller Module from ABB’s Advant Controller 110 (AC 110) series, part of the legacy Advant OCS (Open Control System) and MOD 300 families. The code PM511V16 identifies the specific controller model, with the V16 suffix likely indicating a particular memory size or performance level. The part number 3BSE011181R1 is ABB’s unique Material Ordering Code (MOC) that defines the exact hardware configuration, revision, and orderable item. This module serves as the central brain of a distributed control system (DCS) station, executing complex process control logic, performing calculations, managing communications, and coordinating I/O subsystems.

The value of the PM511V16 lies in its proven reliability, deterministic performance, and deep integration within ABB’s legacy MOD 300 and Advant OCS architectures. It was designed for critical, high-speed process control applications in industries like pulp & paper, chemicals, and power generation. As a key component of the AC 110 station, it provided a powerful computing platform for running the MOD 300’s proprietary real-time operating system and application software. For organizations maintaining these long-lifecycle control systems, the PM511V16 represents a critical spare part whose availability and authenticity are paramount for ensuring the continued, stable operation of production processes.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

ABB PM511V16 3BSE011181R1

|

|

Manufacturer

|

ABB (ASEA Brown Boveri)

|

|

Product Series

|

Advant Controller 110 (AC 110) for MOD 300/Advant OCS

|

|

Product Type

|

Central Processing Unit (CPU) Module

|

Core Processing

-

Processor: Likely a high-performance Motorola 68000 series or similar 32-bit microprocessor, optimized for real-time control tasks.

-

Memory: The V16 suffix often denotes a specific Memory Configuration. It likely includes both volatile (RAM) and non-volatile (ROM/Flash) memory for the operating system, application code, and process data. Memory size would be in the range of several megabytes, substantial for its era.

-

Real-Time Operating System: Runs ABB’s proprietary, deterministic real-time OS for the MOD 300 system.System Integration

-

Backplane Interface: Connects to the AC 110 station’s PI-bus (Parallel Interface bus) for high-speed communication with other station modules (I/O processors, communication modules).

-

Serial Communication Ports: Includes RS-232/RS-485 ports for local configuration, printer connection, or peer-to-peer communication.

-

LED Indicators: Extensive front-panel LEDs for status indication (RUN, FAULT, BATTERY, COM, etc.).

-

Battery Backup: Integrated battery (or capacitor) for retaining RAM data (e.g., application code, setpoints) during a power loss.Performance

-

Scan Time: Capable of fast, deterministic control loop execution, suitable for complex regulatory and sequence control.

-

I/O Capacity: Can manage a large number of I/O points through connected I/O subsystems (e.g., via CI520/CB520 I/O Processors).Environmental

-

Operating Temperature: Typically 0 to 60°C (32 to 140°F)

-

Power Supply: Powered from the AC 110 station’s backplane. Requires a clean 5V DC supply from the station’s power module.

Key Features and Advantages

Deterministic Real-Time Control Engine: The PM511V16 was engineered for mission-critical process control, providing predictable and fast execution of control algorithms. This determinism was essential for applications like paper machine control, turbine control, and batch reactor sequencing.

High Reliability and Robust Architecture: As a core component of the MOD 300 system, it was built for 24/7 operation in industrial environments. Its design emphasized stability and mean time between failures (MTBF), which is why many of these systems remain in operation decades later.

Central Role in a Cohesive Ecosystem: The PM511V16’s primary advantage was its seamless integration within the ABB MOD 300/Advant OCS. It was configured, programmed, and monitored using ABB’s dedicated engineering tools (like MOD 30 software), ensuring a unified and reliable control platform. Its PI-bus provided a high-bandwidth, deterministic connection to I/O and communication modules, forming a powerful and cohesive station.

Application Areas

The ABB PM511V16 was deployed as the main controller in ABB MOD 300 and Advant OCS DCS systems across a wide range of heavy process industries.

Typical applications included:

-

Pulp and Paper Mills: Controlling entire paper machines, from stock preparation to the reel.

-

Chemical and Petrochemical Plants: Managing complex continuous and batch processes.

-

Power Generation: Performing boiler control, turbine sequencing, and balance-of-plant control.

-

Metals and Mining: Controlling rolling mills, pelletizing plants, and material handling.

Essentially, it served as the primary process controller in any facility that standardized on the ABB MOD 300 DCS platform.

Related Products

-

AC 110 Station Rack/Chassis: The physical enclosure and backplane that houses the PM511V16 and other modules.

-

Power Supply Module (e.g., SD522): Provides regulated power to the station backplane.

-

I/O Processor Module (e.g., CI520, CB520): Modules that interface the PM511V16 to the field I/O subsystems (S600 I/O).

-

Communication Modules (e.g., CI522, CI525): For network communication (e.g., to operator stations, other controllers).

-

Operator Station (e.g., Advant Station 500系列): The HMI interface for operators.

-

Engineering Workstation: Running MOD 30 or Advant Engineering software for configuration and programming.

-

Memory Cards/Battery: Specific battery pack for memory backup.

Reviews

There are no reviews yet.