Description

Product Overview

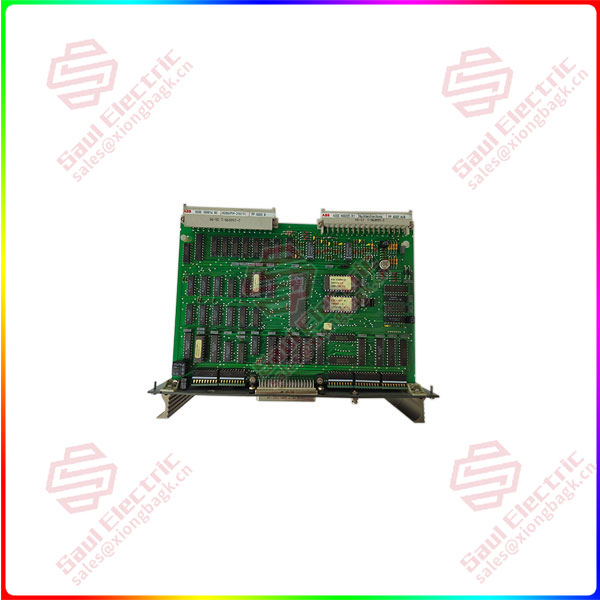

ABB PPB022DE HIEE300867R0001 is a fieldbus or communication interface module for the ABB Symphony Harmony/Plus and 800xA distributed control system (DCS) platforms. The part number is typically decoded as: PPB022DE indicates the core functional model, and HIEE300867R0001 is the full order code/material number. This module serves as a critical interface or network adapter that facilitates communication between the higher-level DCS controllers (e.g., via INFI-NET) and lower-level I/O subsystems or field devices using protocols like HART, PROFIBUS-DP/PA, or other fieldbus standards. It acts as a gateway, protocol translator, and signal conditioner within the ABB’s modular I/O architecture (often part of the S800 or S900 I/O family).

The core value of the ABB PPB022DE HIEE300867R0001 lies in its role as a flexible and reliable communication bridge, enabling the integration of diverse field devices into the unified ABB Symphony/800xA DCS environment. In complex process plants like power generation, oil & gas, and chemical facilities, this module allows ABB controllers to communicate with and manage a wide array of intelligent field instruments (HART-enabled transmitters, PROFIBUS valve positioners, etc.), third-party PLCs, or remote I/O racks. For system integrators and engineers, it provides a standardized, configurable interface that simplifies system engineering, reduces wiring costs through digital fieldbus networks, and enhances diagnostic capabilities. Its reliability is paramount for maintaining continuous process data flow and control command execution.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

ABB PPB022DE (Full Order Code: HIEE300867R0001)

|

|

Manufacturer

|

ABB (formerly part of the ABB Industrial IT or Symphony product lines)

|

|

Product Family

|

Symphony Harmony/Plus I/O System, 800xA System S800/S900 I/O

|

|

Primary Function

|

Fieldbus Communication Interface Module (e.g., HART Multiplexer, PROFIBUS-DP Slave Interface, or similar I/O Link module)

|

Communication & Interface

-

Primary Interface (to Controller/Network): Connects to the ABB Controller or INFI-NET via a dedicated backplane or serial link. Specific protocol depends on integration (e.g., ModuleBus for S800 I/O).

-

Fieldbus Interface: Typically provides one or more fieldbus ports (e.g., PROFIBUS-DP or HART). This allows connection to: 1) PROFIBUS-DP/PA networks with field devices, or 2) A HART multiplexer network for communicating with HART-enabled analog field instruments.

-

Protocol Support: Functions as a PROFIBUS-DP Slave or a HART Master/Multiplexer, translating between the fieldbus protocol and the ABB controller’s internal data format.

-

Data Exchange: Manages cyclic process data (PV, OP) and acyclic parameter/diagnostic data with field devices.Hardware & Integration

-

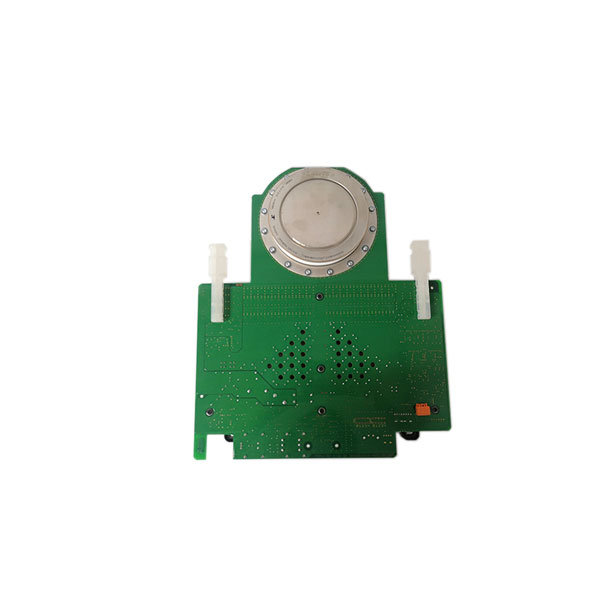

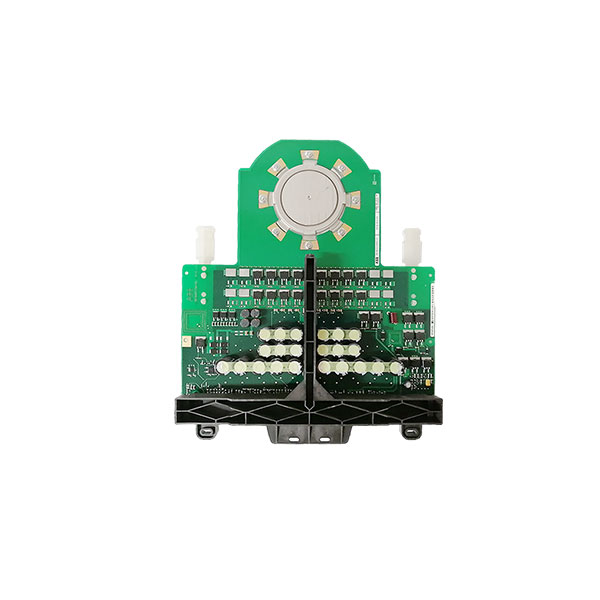

Form Factor: A plug-in module designed for the ABB S800 or S900 I/O Station or Mounting Unit. It slides into a dedicated slot on the station’s baseplate/backplane.

-

Connectors: Typically features front-facing connectors for the fieldbus network (e.g., 9-pin D-sub for PROFIBUS, terminal blocks for HART network) and possibly a connector for local configuration or status.

-

LED Indicators: Multiple status LEDs indicating Module Power, Communication Status (with controller and fieldbus), Active, Fault, and Network Activity.

-

Power Supply: Receives power from the I/O station’s backplane. May also provide power or communication power for the connected fieldbus network (requires configuration).

-

Configuration: Configured using ABB’s engineering tools (e.g., Control Builder M for 800xA, or Symphony Engineer for Harmony). Parameters include fieldbus address, baud rate, and I/O data mapping.Performance & Environmental

-

Operating Temperature: 0 to 60°C (32 to 140°F) typical for control room or sheltered industrial environments.

-

Certifications: Designed for industrial use. When part of a complete ABB system, it complies with relevant industry standards for DCS components.

Key Features and Advantages

Enables Digital Fieldbus Integration: The primary function is to bridge the ABB DCS with industry-standard digital fieldbus networks (PROFIBUS, HART), enabling direct communication with smart field devices. This reduces analog wiring, allows for remote device configuration, and provides access to extensive device diagnostics.

Modular and Flexible Design: As part of the S800/S900 I/O family, it offers a modular approach. The same I/O station can house different interface modules (like the PPB022DE) alongside analog/digital I/O cards, providing a highly flexible and scalable I/O solution.

Enhanced Diagnostics and Asset Management: When used as a HART multiplexer or with PROFIBUS PA devices, it allows the DCS to access device status, calibration data, and diagnostic messages (e.g., sensor drift, device malfunctions) from intelligent field instruments. This supports predictive maintenance and improved asset management.

Simplified System Engineering and Commissioning: Reduces engineering time by allowing field devices to be configured and monitored directly from the ABB engineering workstation. Device parameters and I/O points can be managed within the same project database.

Application Areas

The ABB PPB022DE HIEE300867R0001 is used in ABB Symphony or 800xA DCS installations requiring integration with digital field devices or remote I/O clusters.

-

Power Generation (Thermal, Nuclear, Hydro): Integrating PROFIBUS-based motor starters, drives, or valve actuators into the DCS for boiler control, turbine auxiliaries, or water treatment.

-

Oil & Gas and Petrochemical: Connecting to HART-enabled pressure, temperature, and flow transmitters across vast plants via a HART multiplexer network, centralizing configuration and diagnostics.

-

Chemical and Pharmaceutical Plants: Interfacing with PROFIBUS-PA temperature sensors, level meters, and analytical instruments in hazardous areas.

-

Water and Wastewater Treatment: Communicating with PROFIBUS-DP remote I/O panels located in distributed pump stations or filter buildings.

-

Marine and Offshore: Integrating packaged equipment with its own PROFIBUS-DP control network into the vessel’s main ABB DCS.

Related Products

-

ABB S800/S900 I/O Station: The physical mounting unit and backplane (e.g., CI857, CI854) that provides power, data bus, and slots for the PPB022DE and other I/O modules.

-

ABB AC 800M Controller or Harmony Controller: The DCS controller (e.g., PM861, PM856) that communicates with the PPB022DE module over the ModuleBus or INFI-NET.

-

ABB Engineering Software: Control Builder M Professional (for 800xA) or Symphony Engineer (for Harmony) is required to configure the module, map I/O data, and set fieldbus parameters.

-

Fieldbus Power Supply and Conditioners: For PROFIBUS networks, external bus terminators and possibly a fieldbus power supply/coupler (for intrinsic safety in PROFIBUS-PA) are required.

-

Field Devices: The end instruments: HART transmitters, PROFIBUS-PA sensors/actuators, PROFIBUS-DP variable speed drives (VSDs), motor protection relays, or remote I/O heads.

-

Communication Cables: Standard PROFIBUS cables with 9-pin D-sub connectors or cables for HART networks.

Reviews

There are no reviews yet.