Description

BENTLY 3701/55 323174-01 — Technical Overview

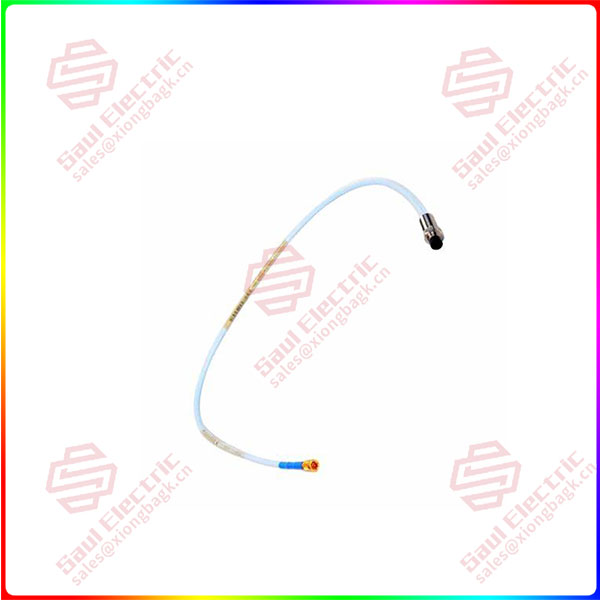

Product: 3701/55, Seismic Velocity Transducer

Manufacturer: Bently Nevada (a Baker Hughes business)

Order/Part Number: 323174-01

Primary Application: An industrial seismic velocity sensor designed for continuous monitoring of absolute casing/bearing housing vibration (in velocity units) on rotating machinery such as turbines, compressors, pumps, fans, and motors.

1. Core Overview & Working Principle

The Bently Nevada 3701/55 is a passive, self-generating velocity transducer (also called a seismoprobe). Unlike eddy current probes that measure relativeshaft displacement, this sensor measures the absolutevibrational velocity of the machine’s casing or structure where it is mounted.

Working Principle:

It operates on the electromagnetic induction principle. The sensor contains a permanent magnet and a coil, with the magnet suspended by springs to form a seismic mass. When the transducer’s housing vibrates (attached to the machine), the magnet tends to remain stationary due to inertia, creating a relative motionbetween the magnet and the coil. This relative motion induces a voltage in the coil that is proportional to the vibrational velocity.

Key Output: The sensor produces an AC voltage signal (mV or Volts) directly proportional to the vibration velocity (e.g., mm/s, in/s). No external power source is required for its basic operation.

2. Key Features

-

Self-Powered: Generates its own signal, requiring no external power supply (2-wire system).

-

Rugged Design: Built for harsh industrial environments with high temperatures, moisture, and vibration.

-

Low-Impedance Output: Provides a robust signal that can be transmitted over long cable runs with minimal noise pickup.

-

Integral Cable: Many versions come with a permanently attached, armored cable for durability.

-

Broad Frequency Range: Typically effective from around 4.5 Hz to 1000 Hz, making it suitable for monitoring vibration related to rotational speeds (1X, 2X) and many common fault frequencies.

3. Model Number Breakdown & Specifications

Common Technical Specifications (Typical for 3701/55):

-

Sensitivity: 100 mV/in/s (±5%) @ 100 Hz (or equivalent in metric, ~4 mV/mm/s).

-

Frequency Response: 4.5 Hz to 1000 Hz (±3 dB). The lower limit (4.5 Hz) is the natural frequency of the suspended magnet system.

-

Measurement Range: Up to 2.0 in/s peak (51 mm/s peak) velocity.

-

Phase Response: Linear within the specified frequency range, allowing it to be used for phase analysis.

-

Electrical Output: Two-wire, ground-isolated.

-

Operating Temperature: Up to 125°C (257°F) for the sensor body.

-

Mounting: Standard ¼-28 UNF threaded stud or M6 x 1.0 threaded stud on the base.

-

Connector: Often an integral cable with a MIL-C-5015 style connector or a BNC connector at the end.

4. System Integration & Signal Conditioning

-

Connection: The transducer is directly connected to a vibration monitor or conditioning module (e.g., Bently Nevada 3300, 3500, or Trendmaster® Pro systems) via its coaxial cable.

-

Signal Path:Machine Vibration → 3701/55 Transducer → Velocity Signal (AC Voltage) → Monitor Input.

-

Conditioning: The monitor may integrate the velocity signal to produce a displacement (µm peak-to-peak) display or perform further processing for alarms and trends.

-

Mounting: Must be securely and rigidly mounted to the machine casing, typically on a clean, flat, unpainted surface, oriented in the desired measurement direction (vertical, horizontal, axial).

5. Typical Applications

-

Casing Vibration Monitoring: Primary method for monitoring vibration on machines with rolling element bearings (e.g., motors, pumps, fans, gearboxes) where shaft-relative probes are not applicable.

-

Low-to-Medium Speed Machinery: Ideal for machines where the fundamental running speed is within the transducer’s frequency range (e.g., > ~300 RPM to account for the 4.5 Hz lower limit).

-

General Machinery Protection: Used in pairs (horizontal and vertical) on bearing housings to detect unbalance, misalignment, looseness, and other mechanical faults.

-

Supplemental Monitoring: Often used alongside shaft-relative probes (like the EPRO PR6423) on fluid-film bearing machines to provide a complete vibration picture.

Reviews

There are no reviews yet.