Description

Product Overview

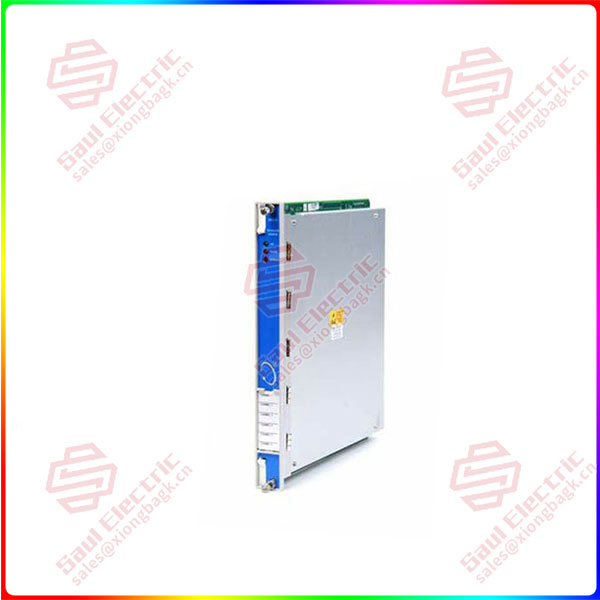

The BENTLY 149986-01E is a high-precision, dual-channel vibration and position monitoring module, specifically the 3500/42M Proximitor® Seismic Monitor, from the renowned Bently Nevada (a Baker Hughes business) 3500 Machinery Health Monitoring System. This module is a cornerstone component designed for continuous, online protection and monitoring of critical rotating machinery. Its primary function is to interface with eddy current proximity probes (for measuring shaft relative vibration and position) and velocity seismic transducers (for measuring casing absolute vibration), conditioning their signals, and providing comprehensive protection based on the processed data. The 149986-01E monitors two completely independent channels, each capable of accepting either a proximity probe input or a seismic transducer input, offering exceptional flexibility for monitoring both shaft and casing vibration on the same module.

The core value of the BENTLY 149986-01E lies in its reliability, advanced diagnostics, and seamless integration within the 3500 system, a global industry standard for machinery protection. Each channel performs sophisticated signal processing, including integration (to convert velocity to displacement for seismic inputs) and filtering. It generates two levels of user-configurable alarms (Alert and Danger) based on overall vibration amplitude, and it continuously monitors the health of the connected sensors, detecting faults such as probe or transducer failure, cable issues (open/short), and system errors. For maintenance and reliability engineers in power generation, oil & gas, and other heavy industries, the 3500/42M module is an essential tool for preventing catastrophic failures. It provides the immediate, trip-level protection needed for safety while also delivering the high-quality vibration data required for condition-based maintenance and diagnostics, forming a critical link between asset protection and predictive maintenance strategies.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

BENTLY 149986-01E (3500/42M Proximitor® Seismic Monitor)

|

|

Manufacturer

|

Bently Nevada (a Baker Hughes business)

|

|

System Platform

|

3500 Machinery Health Monitoring System

|

|

Product Type

|

Dual-Channel Vibration & Position Monitor (Accepts Proximity and Seismic Inputs)

|

|

Number of Channels

|

2 fully independent monitoring channels.

|

|

Input Types (per channel)

|

Configurable for:

|

Key Features and Advantages

BENTLY 149986-01E excels through its versatile dual-input capability and proven reliability. A primary advantage is the ability to use each channel for either a proximity probe (shaft vibration) or a seismic transducer (casing vibration). This flexibility allows a single module to monitor a combination of parameters, such as shaft vibration on one bearing and casing vibration on an adjacent bearing housing, optimizing rack space and system configuration. The module is built upon Bently Nevada’s decades of experience in machinery protection, ensuring measurement accuracy and long-term stability in harsh industrial environments.

Advanced signal conditioning and diagnostic intelligence are fundamental to its protective role. The module’s signal processing is tailored for machinery diagnostics, providing clean, reliable vibration signals. Its most critical feature is the extensive built-in sensor and system diagnostics. It continuously validates the entire measurement chain, from the probe tip to the module’s electronics. The ability to instantly detect a failed probe, broken cable, or loss of signal prevents a dangerous situation where a faulty sensor could mask a genuine machine problem. This diagnostic capability is a key factor in achieving high system availability and safety integrity.

Seamless integration and clear operational interface within the 3500 ecosystem are significant benefits. The module plugs directly into a 3500 rack, working in concert with power supplies, relay modules, and communication gateways. Front-panel LED bargraphs provide an immediate, at-a-glance view of vibration level relative to the alarm setpoints. Dual digital displays show precise vibration values (mils or µm) and gap voltage. Configuration is performed using the handheld 3500 Rack Configuration Software, making setup and adjustment straightforward. For asset managers, the 3500/42M is more than a monitor; it’s a reliable, intelligent component of a comprehensive protection system that safeguards critical assets, provides actionable data, and supports predictive maintenance initiatives, all within a globally trusted platform.

Application Areas

The BENTLY 149986-01E (3500/42M) is deployed for protection and monitoring of critical rotating equipment across all major process industries.

Its primary application is in turbomachinery:

-

Gas Turbines & Steam Turbines: Monitors radial shaft vibration at each journal bearing using proximity probes and casing vibration using seismic transducers. A single module can handle both types on the same machine.

-

Centrifugal & Axial Compressors: Provides essential vibration monitoring for mechanical protection and surge avoidance on critical pipeline, refinery, and process compressors.

-

Large Pumps & Fans: Protects critical boiler feed pumps, induced/forced draft (ID/FD) fans, and main coolant pumps by monitoring both shaft and casing vibration.

-

Hydro Turbines, Generators, Motors, and Gearboxes: Used wherever reliable vibration monitoring is required for equipment protection.

Essentially, the 3500/42M is applied to any high-speed rotating machine where unplanned failure carries significant safety, environmental, or financial risk, and where both shaft-relative and casing-absolute vibration data are valuable for protection and diagnosis.

Related Products

-

Bently Nevada 3300 XL 8mm Proximity Transducer System: The industry-standard proximity probes, extension cables, and proximitors that connect to the proximity input of the 3500/42M.

-

Bently Nevada Seismic Velocity Transducer (e.g., 4-20 mA output): The sensor connected to the seismic input of the module.

-

3500/15 Power Supply: Provides power to the 3500 rack housing the 3500/42M.

-

3500/33 Relay Module: Provides the physical Form-C relay contacts for the Alert and Danger alarms generated by the 3500/42M.

-

3500/92 Communication Gateway: Transmits data from the 3500 rack (including 3500/42M data) to plant DCS, PLC, or Bently Nevada System 1™ software.

-

3500 Rack Configuration Software (Handheld or PC-based): Used to configure all parameters and alarm setpoints for the 3500/42M module.

-

Bently Nevada System 1™ Software: The enterprise asset performance management platform that is a primary destination for historical data and advanced analysis from the 3500 system.

Reviews

There are no reviews yet.