Description

Product Overview

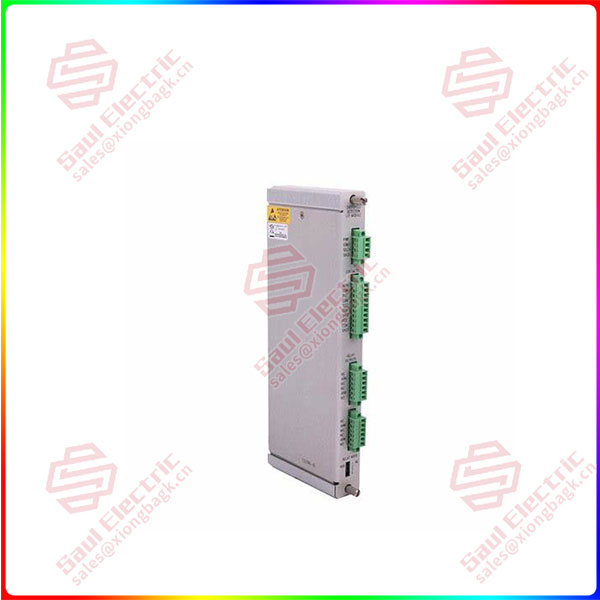

The GE IS200TRLYH1BHH is a specialized High-Speed Digital Input Module from the General Electric (GE) Mark VI Speedtronic™ gas/steam turbine control system. The module designation «TRLY» strongly suggests it is a Trip Relay interface or a high-integrity digital input module dedicated to critical protection signals. This module is designed to acquire the status of vital safety and permissive contacts, such as those from overspeed protection devices, vibration monitors (TSI), lube oil pressure switches, and other emergency trip sensors. Its primary function is to provide a fast, reliable, and isolated interface for these critical binary signals, converting contact closures (or opens) into digital data for the Mark VI’s protection logic. The module likely incorporates features like filtering, debouncing, and high-grade isolation to ensure signal integrity and immunity to noise, which is paramount for preventing nuisance trips or, more importantly, failing to trip on a genuine fault condition.

The value of the GE IS200TRLYH1BHH lies in its critical role in turbine safety and protection system integrity. It serves as the primary electronic gateway for signals that can command an immediate turbine shutdown. The module’s design emphasizes high availability and diagnostic capability. It may support redundant input configurations (e.g., 2-out-of-3 voting) and continuous self-diagnostics to detect internal faults or failures in the field wiring (open circuit, short circuit). For protection system engineers and turbine operators, the reliable operation of the TRLYH1BHH module is non-negotiable. It ensures that hazardous conditions are detected with the utmost reliability and speed, forming the first and most critical electronic layer in the chain of events that leads to a protective shutdown, thereby safeguarding the turbine, personnel, and surrounding infrastructure.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

GE IS200TRLYH1BHH

|

|

Manufacturer

|

General Electric (GE)

|

|

System Platform

|

Mark VI Speedtronic™ Turbine Control System

|

|

Product Type

|

High-Speed / High-Integrity Digital Input Module (for Trip Signals)

|

|

Input Channels

|

Likely provides multiple (e.g., 8, 16) isolated digital input channels dedicated to critical trip/permissive signals.

|

|

Input Type

|

Configurable for dry contact (volt-free) or wet contact sensing (e.g., with 24/48/125 V DC field power). Designed for high-integrity switch inputs.

|

|

Response Time

|

Extremely fast response time (typically in the millisecond range) to ensure rapid reaction to trip conditions.

|

|

Isolation

|

High-grade optical or transformer isolation between each input channel and between the field side and the system electronics. Isolation voltage is typically 1500-2500 Vrms to withstand transients.

|

|

Diagnostics

|

Comprehensive per-channel diagnostics: Field Wire Break (Open Circuit) Detection, Field Short Circuit Detection, Loss of Field Power, and Module Internal Fault monitoring. These diagnostics are critical for a protection system.

|

|

Voting Logic Support

|

The module or the system configuration may support 2-out-of-3 (2oo3) or other voting schemes on multiple inputs representing the same physical parameter (e.g., three overspeed probes) to enhance availability and prevent spurious trips.

|

|

Configuration

|

Configured using GE’s ToolboxST software. Settings include input type (sourcing/sinking), filter/debounce time, and assignment of the input to specific protection logic blocks.

|

|

Status Indication

|

Front-panel LEDs for each channel indicating input state (ON/OFF) and likely separate LEDs for channel fault or module health.

|

|

Power Supply

|

Powered from the Mark VI rack backplane. May also provide or require external field power for wet contacts.

|

|

Mounting

|

Installs in a designated slot within a Mark VI I/O rack.

|

|

Operating Temperature

|

0°C to 60°C (for control cabinet environment).

|

|

Certifications

|

Designed to meet stringent requirements for machinery protection, potentially influencing relevant segments of standards like IEC 61508 (Functional Safety).

|

Key Features and Advantages

GE IS200TRLYH1BHH is distinguished by its focus on safety-critical signal acquisition. Its foremost advantage is providing a fast and ultra-reliable interface for trip signals. The combination of high-speed response and robust noise immunity ensures that a genuine trip condition is communicated to the controller with minimal delay and without being masked by electrical interference. The module’s design prioritizes failure detection over failure masking; it is more likely to cause a safe shutdown (fail-safe) than to ignore a dangerous condition.

Advanced diagnostics and high availability design are engineered into its core. The ability to detect an open circuit or short circuit in the field wiring to a critical switch (like an overspeed bolt) is vital. Without this diagnostic, a broken wire could be misinterpreted as a «healthy, no-trip» signal. This diagnostic capability directly supports high Safety Integrity Levels (SIL). Support for redundant voting configurations (when used with multiple sensors and modules) allows the system to tolerate a single sensor or single input channel failure without causing a nuisance trip or losing protection, thereby maximizing turbine availability while maintaining safety.

Seamless integration and deterministic operation within the Mark VI ecosystem are key benefits. As a genuine Mark VI component, it integrates flawlessly with the controller’s protection logic programmed in ToolboxST. Its operation is deterministic, meaning its scan time and response are predictable, which is essential for safety system analysis. For system designers, the TRLYH1BHH provides a certified, reliable building block for implementing the sensor interface layer of the turbine’s protection system, reducing engineering risk and complexity for the most critical part of the control system.

Application Areas

The GE IS200TRLYH1BHH module is deployed exclusively for interfacing with critical protection and permissive devices in GE Mark VI turbine control systems.

Its specific applications include acquiring signals from:

-

Overspeed Protection System: Signals from mechanical overspeed bolts or electronic overspeed detectors.

-

Turbine Supervisory Instrumentation (TSI): Trip signals from vibration monitors, axial position monitors, and eccentricity monitors.

-

Lube Oil System: Low lube oil pressure switches and high bearing temperature switches.

-

Other Emergency Trip Devices: Fire detection system outputs, manual emergency stop buttons, and critical process interlocks (e.g., low vacuum for steam turbines).

Essentially, any contact or switch whose change of state is designed to cause an immediate or sequenced shutdown of the turbine is a candidate for connection to a TRLY series module. It forms the electronic sensory foundation of the turbine’s protection and safety shutdown system.

Related Products

-

Field Trip Sensors: Overspeed bolts, pressure switches, vibration transmitters with trip contacts.

-

GE Mark VI Controller: Executes the protection logic that processes the trip signals from the TRLY module.

-

GE Mark VI Relay Output Modules: The modules that ultimately energize the shutdown solenoids/valves based on the trip logic.

-

Redundant TRLY Modules & Sensors: For implementing 2oo3 or other redundant voting schemes.

-

GE ToolboxST Software: Used to configure the module, define trip logic, and set up diagnostics.

-

Termination Panels: For marshalling field wiring to the module.

Reviews

There are no reviews yet.