Description

Product Overview

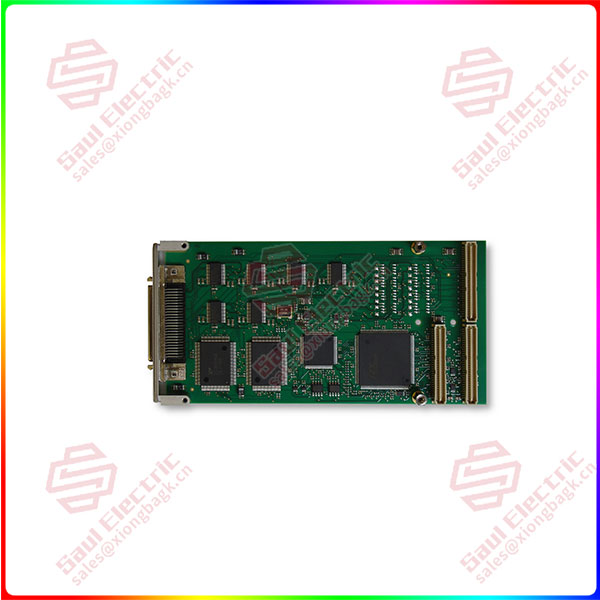

The EMERSON TPMC917 is a high-performance, modular Controller Interface Module (CIM), a key intelligent component within the Emerson ControlWave series of Programmable Automation Controllers (PACs) and Remote Terminal Units (RTUs). This module serves as the versatile and ruggedized interface between the core ControlWave controller’s backplane and the external world of field devices. Its primary function is to extend the I/O (Input/Output) and communication capabilities of the host controller, allowing it to connect to a wide array of analog and digital field signals, as well as to various industrial networks. The EMERSON TPMC917 is not a standalone controller, but rather an essential expansion unit that houses and manages a configurable mix of I/O modules (specific to the ControlWave platform), providing signal conditioning, isolation, and local processing intelligence at the field interface level.

As part of Emerson’s robust solution for process control, telemetry, and SCADA systems, the TPMC917 is engineered for deployment in challenging environments, including remote, unattended locations. It can operate as a satellite I/O node communicating with a central ControlWave master over networks like ControlWave Link, Ethernet, or serial links, or it can be directly mounted alongside a ControlWave CPU. Its value lies in its flexibility, reliability, and distributed intelligence. It can execute simple control logic locally, reducing communication load on the master controller and improving system responsiveness. For system integrators in the oil & gas, water/wastewater, and pipeline industries, the EMERSON TPMC917 provides a scalable, reliable, and configurable platform to gather data from geographically dispersed assets and execute precise control, forming a critical link in distributed automation architectures.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

EMERSON TPMC917

|

|

Manufacturer

|

Emerson Automation Solutions

|

|

Product Series

|

ControlWave Series

|

|

Product Type

|

Controller Interface Module (I/O & Communication Expander)

|

|

Form Factor

|

Modular, rack-mountable chassis designed to hold ControlWave compatible I/O modules.

|

|

Primary Function

|

I/O concentration, signal conditioning, and local communication management.

|

|

Backplane Interface

|

Connects to a ControlWave controller (e.g., ControlWave LP, ControlWave Micro) via a high-speed parallel or serial backplane link, or operates as a remote node.

|

|

I/O Capacity

|

Houses multiple slots (e.g., 4, 8, or 12 slots) for a mix of ControlWave I/O modules (analog input/output, digital input/output, serial communication, etc.).

|

|

Onboard Intelligence

|

Features a local microprocessor for managing I/O, executing simple logic/scripts, and handling communications, offloading the main CPU.

|

|

Communication Ports

|

Multiple built-in ports, typically including: Ethernet (10/100Base-T), serial ports (RS-232/485), and often a dedicated port for ControlWave Link (CWL) network for connecting to other ControlWave devices.

|

|

Power Supply

|

Accepts a wide-range DC or AC input (e.g., 9-36 V DC, 85-264 V AC), typical for field installations.

|

|

Operating Temperature

|

Wide operating range, typically -40°C to +70°C, suitable for harsh outdoor environments.

|

|

Environmental Protection

|

Robust metal housing, typically rated at least IP30 for indoor use, and can be installed in higher-rated enclosures for outdoor use.

|

|

Certifications

|

Designed to meet industrial standards: cULus, ATEX/IECEx Zone 2 (when installed appropriately), CE.

|

Key Features and Advantages

EMERSON TPMC917 excels as a flexible and intelligent I/O concentrator for distributed systems. Its core advantage is the ability to be configured with a precise mix of I/O modules to match the exact requirements of a field site—be it a pump station, wellhead, or remote tank farm. This modularity eliminates the need for over-engineering or under-provisioning, optimizing cost and performance. The module’s onboard intelligence allows it to perform data pre-processing, scaling, alarming, and even execute simple control sequences (like pump alternation) locally. This reduces the bandwidth requirements and latency in SCADA systems and ensures continued basic operation even if communication to the master station is temporarily lost.

Robust communication and network resilience are fundamental to its design. With multiple independent communication ports, the TPMC917 can be connected to various networks simultaneously. For example, Ethernet can be used for SCADA communication, an RS-485 port can connect to Modbus RTU devices (like flow meters), and the ControlWave Link can daisy-chain to other remote I/O units. This makes it an excellent protocol gateway and data concentrator. Its wide operating temperature range and rugged construction ensure reliable operation in unconditioned shelters or outdoor enclosures, which is critical for remote telemetry applications.

Simplified engineering and maintenance are significant benefits. The TPMC917 and its I/O modules are configured using Emerson’s ControlWave Designer software, providing a unified engineering environment for hardware configuration, control logic programming, and HMI design. The modular, hot-swappable design (for I/O modules) allows for easy maintenance and expansion without taking the entire unit offline. Clear status LEDs on the front panel provide immediate visual health indication. For system designers, the EMERSON TPMC917 offers a future-proof, scalable building block that simplifies the architecture of distributed control and monitoring systems, reduces installation and wiring costs, and enhances overall system availability and responsiveness.

Application Areas

The EMERSON TPMC917 is designed for distributed control and monitoring applications across multiple industries, particularly where reliability in remote or harsh environments is key.

In the water and wastewater industry, it is extensively used as a remote telemetry unit (RTU) at pump stations, lift stations, reservoir sites, and treatment plants to monitor levels, flows, pressures, and control pumps and valves. For oil & gas production, it is deployed at wellheads, satellite stations, and tank batteries to monitor pressure, temperature, and control emergency shutdown (ESD) functions, often communicating via radio or cellular networks.

Within pipeline SCADA systems, it serves as a field controller for block valve stations, compressor/pump stations, and custody transfer metering sites, gathering data from multiple instruments. In renewable energy, it can monitor and control solar farm inverters or small wind turbine installations. It is also used in industrial facilities for distributed process control and equipment monitoring where a rugged, modular I/O solution is needed. Essentially, the EMERSON TPMC917 is the ideal platform for any application requiring a configurable, intelligent, and rugged I/O interface node that must operate reliably as part of a larger distributed automation network.

Related Products

-

EMERSON ControlWave LP or Micro Controller: The main processor unit that the TPMC917 typically interfaces with as an expansion chassis or remote node.

-

EMERSON ControlWave I/O Modules (e.g., AI, AO, DI, DO, COMM): The specific signal conditioning modules that plug into the slots of the TPMC917 chassis.

-

EMERSON ControlWave Designer Software: The integrated development environment for configuring hardware, programming control strategies, and designing operator interfaces for the entire ControlWave system.

-

EMERSON ControlWave Link (CWL) Repeaters/Extenders: For extending the distance of the daisy-chained ControlWave network connecting multiple TPMC917 units.

-

EMERSON ROC800-Series RTU: Another Emerson RTU platform for flow measurement and control, representing a different product line.

-

Power Supply Modules: Dedicated AC/DC or DC/DC power supplies compatible with the ControlWave platform for powering the TPMC917.

-

Enclosures: NEMA 4X or explosion-proof enclosures for housing the TPMC917 in harsh or hazardous outdoor locations.

-

Communication Radios/Modems: Devices to provide the wireless backhaul (e.g., cellular, licensed radio) for remote TPMC917 installations.

Reviews

There are no reviews yet.