Description

EPRO PR6424/000-030 + CON021 — Complete Eddy Current Measurement System

Product Combination: PR6424/000-030 (Eddy Current Probe) + CON021 (Driver/Proximitor)

Manufacturer: EPRO (now part of Baker Hughes)

System Type: Complete non-contact displacement measurement system for monitoring radial shaft vibration, axial thrust position, and differential expansion in rotating machinery.

1. Core Overview & System Components

This combination represents a complete, calibrated measurement channel for machinery condition monitoring. The system consists of two main components that must be used together:

-

PR6424/000-030: The eddy current proximity probe (sensor).

-

CON021: The oscillator/driver module (proximitor) that powers the probe and converts the gap measurement into standard voltage signals.

Key Concept: These components are calibrated and matched as a set. The probe cannot function without the driver, and the driver’s output is only accurate when used with its specifically calibrated probe.

2. Component 1: PR6424/000-030 — Eddy Current Probe

Probe Specifications:

-

Diameter: 8 mm (industry standard).

-

Sensitivity: When used with the matching CON021 driver, the combined system sensitivity is typically 8.0 mV/µm (200 mV/mil). The exact value is on the system calibration sheet.

-

Linear Range: Typically 2.0 mm (e.g., from 1.0 mm to 3.0 mm from the probe tip).

-

Temperature Range: Up to 120°C for the standard version (higher with different suffixes).

-

Cable: Integral, armored cable, 3.0 meters long, with connector.

3. Component 2: CON021 — Driver/Proximitor Module

-

CON021: Specific model in the CON0xx series of driver modules. The «21» variant defines its electrical characteristics and form factor.

Driver Function & Specifications:

-

Purpose: Provides a high-frequency excitation current to the probe and demodulates the probe’s impedance change (caused by the gap to the target) into two useful DC voltage signals:

-

Gap Voltage (Static DC): A negative DC voltage (typically -2V to -18V) proportional to the average distance between the probe tip and the shaft (for position monitoring).

-

Vibration Voltage (Dynamic AC): A superimposed AC voltage (typically 0-20V peak-to-peak) proportional to the dynamic motion of the shaft (for vibration monitoring).

-

-

Power Supply: Typically requires ±15 V DC or +24 V DC, depending on the specific CON021 variant.

-

Output Signals: Provides both gap (DC) and vibration (AC) signals simultaneously.

-

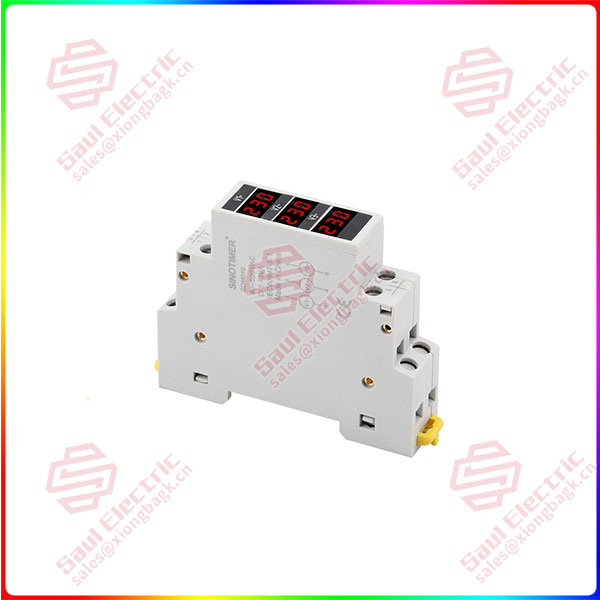

Form Factor: Usually a small, encapsulated module designed for DIN-rail or direct PCB mounting within a monitoring system rack.

4. Complete System Operation

-

The CON021 driver sends a high-frequency (e.g., 1-2 MHz) signal to the PR6424 probe.

-

The probe’s coil creates an electromagnetic field. When near a conductive shaft, eddy currents are induced.

-

The distance (gap) affects these eddy currents, changing the probe coil’s impedance.

-

The CON021 detects this impedance change and outputs the corresponding Gap DC Voltage and Vibration AC Voltage.

-

These signals are connected to a monitoring system (like an EPRO MMS6000 module) which scales them using the calibration data and generates alarms, 4-20mA outputs, etc.

System Calibration: The PR6424/000-030 probe and CON021 driver are calibrated together as a matched pair. Their calibration sheet provides the exact:

-

System Sensitivity: e.g., 8.00 mV/µm.

-

Linear Range: e.g., 0.5 mm to 2.5 mm.

-

Valid for a specific target material (usually mild steel AISI 4140).

5. Typical Installation & Integration

-

Mounting: The probe is installed in a threaded or flanged holder on the machine casing, aimed perpendicular to the shaft. The initial gap is set to the mechanical center of the linear range (e.g., -10 V DC).

-

Wiring: The probe’s cable connects to the CON021 driver. The driver’s output signals are wired to a vibration monitor/PLC.

-

System Integration: Used in pairs (X and Y direction) per bearing for radial vibration measurement, or singly for axial position measurement.

Reviews

There are no reviews yet.