Description

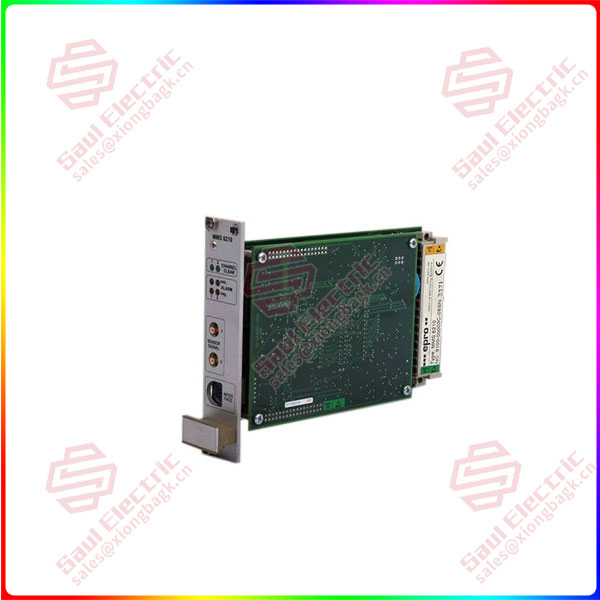

EPRO PR9350/02-811 — Two-Wire Vibration/Position Transmitter

Product: PR9350/02-811, 4-20 mA Vibration/Position Transmitter

Manufacturer: EPRO (now part of Baker Hughes)

Product Line: PR 9350 Series

Primary Application: A loop-powered, two-wire vibration and position transmitter that converts signals from eddy current proximity probes (for radial vibration or axial position) into standard 4-20 mA analog outputs for integration with PLCs, DCS, SCADA, or other monitoring systems.

1. Core Overview & Working Principle

The EPRO PR9350/02-811 is a compact, field-mountable signal conditioner and isolator. It serves as the interface between non-contact eddy current measurement systems (probe, extension cable, and driver) and plant control/monitoring systems.

Working Principle:

The transmitter accepts the analog voltage signals from a compatible proximity probe system (typically -2 to -18 V DC for gap, plus an AC component for vibration). It conditions, scales, and converts these signals into one or more 4-20 mA current outputs that are linearly proportional to the measured parameter (vibration in µm peak-to-peak or position in mm). Being two-wire loop-powered, it requires no separate power supply—it operates on the same 2-wire circuit that carries the output signal.

2. Key Features & Functions

-

Loop-Powered (2-Wire Operation): Simplifies installation and reduces wiring costs; powered by the 4-20 mA loop (typically 12-30 V DC from the receiving device).

-

Dual-Channel Capability: The /02 in the model number indicates it is a two-channel device. It can process two independent input signals (e.g., from X and Y probes on a bearing) and provide two independent 4-20 mA outputs.

-

Wide Input Compatibility: Configurable via DIP switches to accept signals from industry-standard proximity probes with sensitivities of 4.0 mV/µm, 8.0 mV/µm (200 mV/mil), or 20 mV/mil.

-

Field-Configurable Ranges: Output scaling (0% to 100% = 4 to 20 mA) is easily set to match common measurement ranges (e.g., 0-100 µm, 0-200 µm for vibration; 0-2 mm, 0-4 mm for position).

-

Local Bargraph Display: Features a built-in, multi-segment LED bargraph for each channel, providing instant local visual indication of the vibration or position level.

-

Robust Housing: Housed in a sturdy, sealed metal enclosure with a high IP rating (e.g., IP65), making it suitable for mounting directly in harsh industrial environments near machinery.

-

Electrical Isolation: Provides galvanic isolation between the input (probe side) and output (loop side), protecting control system electronics from ground loops and transients.

3. Model Number Breakdown & Specifications

Typical Technical Specifications:

-

Number of Channels: 2 independent channels.

-

Input Signal: From eddy current probe system (e.g., EPRO CON0x1 driver). Compatible with standard 8 mm or 11 mm probes.

-

Output Signal: 2 isolated 4-20 mA signals, linear with input.

-

Power Supply: 12-30 V DC, loop-powered (2-wire per channel).

-

Measurement Ranges (Selectable): Vibration: 0-25/50/100/200/400 µm pp. Position: 0-1/2/4 mm.

-

Accuracy: Typically better than ±1% of full scale.

-

Frequency Response: 0.5 Hz to 3000 Hz (for vibration).

-

Display: 10-segment LED bargraph per channel.

-

Operating Temperature: -30°C to +80°C.

-

Enclosure: Aluminum, IP65.

4. System Integration & Configuration

-

Installation: Mounts on a DIN rail, panel, or directly on machinery via its integral bracket. Installed in a local junction box close to the probes to minimize analog signal cable runs.

-

Wiring:

[Probe A + Driver] ----> Input 1 (PR9350/02-811) ----> 4-20mA Out 1+ -----> [PLC/DCS Analog Input] [Probe B + Driver] ----> Input 2 4-20mA Out 2+ (providing loop power) | | Out 1- -----------------------| Out 2- -----------------------| -

Configuration (via DIP Switches & Pots):

-

Set the probe sensitivity (e.g., Switch 1-2 for 8.0 mV/µm).

-

Set the measurement range (e.g., Switches 3-5 for 0-100 µm).

-

Fine-tune 4mA (Zero) and 20mA (Span) using internal potentiometers for each channel if precise calibration is needed.

-

-

Role: Provides a simple, reliable, and standardized interface to bring critical machinery health signals into a plant’s wider control and monitoring network for trending, alarming, and basic operational decisions.

5. Typical Applications

-

Basic Machinery Monitoring: Adding vibration/position monitoring to pumps, fans, compressors, and turbines where signals need to feed into an existing plant DCS/PLC.

-

Auxiliary Equipment: Monitoring less critical machines where a full protection system is not warranted.

-

OEM Integration: Built into skids or machines by OEMs to provide a standard analog output for health monitoring.

-

Retrofits: Upgrading existing machinery with modern monitoring capability without installing a full rack-based system.

Reviews

There are no reviews yet.