Description

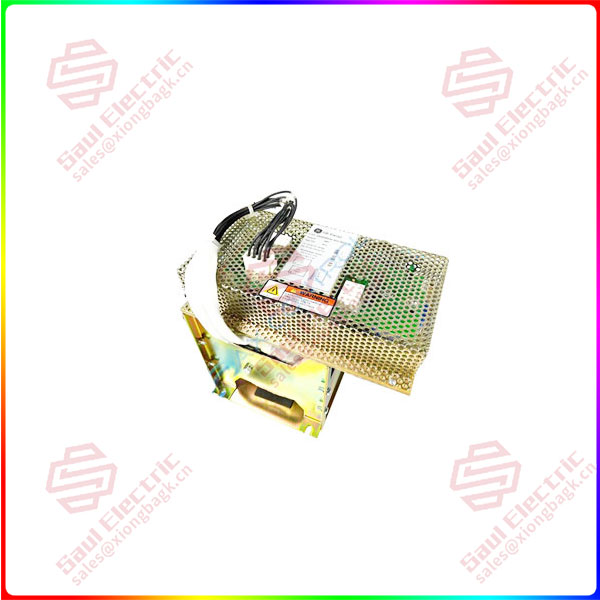

GE DS2020DACAG2 — I/O Module

Product: DS2020DACAG2, Data Acquisition & Control I/O Module

Manufacturer: General Electric (GE), part of the Mark VIe Speedtronic Turbine Control System family

Primary Application: A specialized data acquisition and control I/O module within GE’s Mark VIe control platform, designed for handling specific analog or digital signals in gas/steam turbine control and protection systems.

1. Core Overview & System Context

The GE DS2020DACAG2 is a component within the DS200 I/O pack series for the Mark VIe control system. Mark VIe is GE’s distributed control architecture for turbine management. The «DACA» in the part number typically indicates a specific function group (e.g., Digital/Analog Control Acquisition). The «G2» suffix denotes Generation 2 hardware.

Key Function: It acts as an interface between the turbine’s field devices (sensors, switches) and the Mark VIe controllers, providing signal conditioning, isolation, and conversion for critical control and protection loops.

2. Key Features & Functions

-

Signal Conditioning: Provides isolation and scaling for various field signals.

-

High-Density I/O: Likely configured with a mix of:

-

Analog Inputs (AI): For 4-20mA, 0-10V, or RTD/thermocouple signals (e.g., temperatures, pressures).

-

Digital Inputs (DI): For contact status, switch closures.

-

Analog Outputs (AO): For 4-20mA control signals.

-

Digital Outputs (DO): For relay commands, alarms.

-

-

Deterministic Performance: Designed for real-time control with predictable scan times.

-

Hot-Swappable: Can be replaced online in redundant configurations without shutting down the turbine.

-

Diagnostics: Includes self-diagnostics and channel-level fault detection.

-

Direct Integration: Plugs into a Mark VIe I/O pack and communicates with the controller via the PDH (Plant Data Highway) or UDH (Unit Data Highway) network.

3. Common Technical Specifications

-

Part Number Breakdown:

-

DS2020: Series identifier for Mark VIe I/O modules.

-

DACA: Data Acquisition & Control Analog (specific function code).

-

G2: Generation 2 hardware revision.

-

-

Channels: Exact count and type (e.g., 8 AI, 8 DI, 4 AO) defined by the «DACA» configuration. Refer to GE’s I/O module guide.

-

Isolation: Channel-to-channel and channel-to-system isolation for noise immunity.

-

Power: Powered by the I/O pack backplane.

-

Communication: Via the Mark VIe I/O network to the main controller.

-

Form Factor: Printed circuit board (PCB) that slides into a designated slot in a DS200 I/O Pack.

4. System Integration

-

Location: Installed in a Mark VIe I/O Pack (e.g., a TBCI or similar enclosure) located near the turbine or in the control cabinet.

-

Signal Flow:

-

Field sensors/switches wire to the Terminal Board associated with the I/O pack.

-

Terminal Board connects to the DS2020DACAG2 module.

-

Module conditions and digitizes the signals.

-

Data is sent via the backplane to the Mark VIe Controller (TMR, simplex, or duplex).

-

The controller executes the control logic and sends commands back through output channels.

-

-

Configuration: The module’s scaling and parameters are defined in the Mark VIe control configuration using ToolboxST software.

5. Typical Applications in Turbine Control

-

Analog Monitoring: Lube oil temperature/pressure, fuel gas pressure, bearing temperatures (via RTDs), vibration signals.

-

Discrete Status: Valve limit switch feedback, pump running status, flame detector signals.

-

Control Outputs: Positioning signals for auxiliary devices, alarm annunciation outputs.

-

Protection Loops: Part of input chains for safety-critical shutdown signals.

Reviews

There are no reviews yet.