Description

GE IS200WROBH1A — Technical Overview

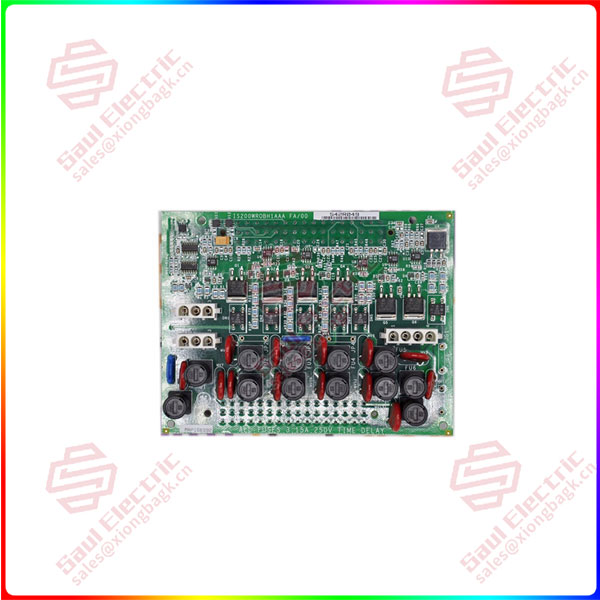

Product: IS200WROBH1A, Turbine Control Module

Manufacturer: General Electric (GE), part of the Mark VIe Speedtronic Turbine Control System

Primary Application: A specialized control and protection module within GE’s Mark VIe system, designed for critical rotor speed, vibration monitoring, and overspeed protection functions in gas and steam turbines.

1. Core Overview & System Context

Primary Role: It is a critical component dedicated to rotor protection, likely integrating functions for:

-

Overspeed detection and protection (triple-redundant safety).

-

Vibration monitoring from proximity probes or accelerometers.

-

Bearing temperature or health monitoring.

-

Keyphasor® signal processing for phase reference.

2. Key Features & Functions

-

High-Speed Signal Processing: Dedicated to processing high-frequency signals from magnetic pickups (MPUs) or proximity probes for precise speed measurement.

-

Redundant Safety Architecture: Likely part of a Triple Modular Redundant (TMR) or dual-channel overspeed protection chain, providing a 2-out-of-3 voting logic to prevent nuisance trips while ensuring failsafe operation.

-

Integrated Diagnostics: Continuous self-diagnostics for internal hardware and connected sensor health (open circuit, short circuit detection).

-

Deterministic Performance: Engineered for ultra-fast, predictable response times (critical for overspeed trips, often <10 ms).

-

Event Recording: Captures detailed event sequences and waveform data leading up to and during a trip for post-event analysis.

-

Communication: Integrates with the Mark VIe controller via the system backplane (VME) or network (PDH), reporting status and receiving configuration.

3. Common Technical Specifications (Inferred)

-

Speed Inputs: Accepts signals from multiple (e.g., 2 or 3) MPUs observing a gear on the turbine shaft. Typical frequency range up to 20 kHz.

-

Vibration/Temperature Inputs: May have auxiliary inputs for conditioning signals from vibration transducers or RTDs.

-

Outputs: Includes relay outputs or logic signals to initiate a Master Protective Trip (MPT) to the turbine’s fuel shutoff valves.

-

Power Supply: Powered by the Mark VIe rack’s DC supply (e.g., 125 V DC or 24 V DC).

-

Form Factor: A single-slot VME board designed for installation in a Mark VIe controller or I/O rack.

-

Accuracy: Extremely high for speed measurement (e.g., ±0.1% of reading or better).

4. System Integration

-

Location: Installed in a Mark VIe I/O pack or controller rack dedicated to protection functions.

-

Role in Safety Loop: It functions as part of the independent safety system (often called the «Overspeed Protection System» or «Emergency Trip System«), which operates in parallel to, but is separate from, the primary control governor.

-

Sensor Integration: Connected to dedicated, shielded cables from the turbine-mounted MPUs. These sensors are often installed specifically for protection, separate from those used for control.

-

Wiring: Its trip outputs are typically hardwired in series with the turbine’s Master Trip Solenoids or Trip Relays.

5. Typical Applications

This module is a cornerstone of turbine safety in:

-

Heavy-Duty & Aeroderivative Gas Turbines for power generation.

-

Steam Turbines in utility and industrial plants.

-

Any GE turbine installation where a certified, high-integrity overspeed protection system is required (often for insurance or regulatory compliance).

Reviews

There are no reviews yet.