Description

Product Overview

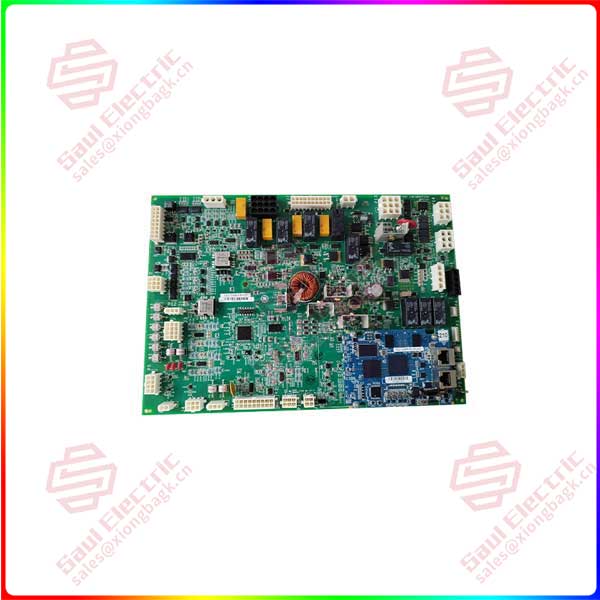

The GE IS215WEPAH2BB is a highly specialized and critical I/O (Input/Output) termination board, specifically designed as a field interface module for the GE Mark VIe gas/steam turbine control system. This board is a fundamental component within the Mark VIe architecture, serving as the primary physical and electrical interface between the turbine’s field devices—such as sensors (thermocouples, RTDs, pressure transmitters), actuators (solenoid valves, servo drives), and contactors—and the system’s central controllers and network. Functioning as a robust signal conditioning and distribution point, the GE IS215WEPAH2BB terminates raw field wiring, provides necessary isolation and conditioning, and routes these signals to and from the system’s high-speed VME-based I/O packs (like the WEPA series). Its role is pivotal in ensuring signal integrity, reducing electrical noise, and providing a reliable, maintainable connection point in the harsh environment of a turbine enclosure.

As part of the Mark VIe «Enhanced» platform, the WEPAH2 variant denotes specific characteristics, likely related to its mix of analog and discrete I/O channels, connector types, and its compatibility with specific I/O packs (like the IS215WEPAH2A, an analog input pack). The board’s design emphasizes modularity and serviceability; it is typically mounted in a rack or panel and uses high-density, keyed connectors to mate with the corresponding I/O pack, allowing for easy replacement of the electronic pack without disturbing the field wiring. For turbine control engineers and maintenance personnel, the GE IS215WEPAH2BB represents the foundational layer of the control system’s I/O hierarchy. Its proper configuration, wiring, and maintenance are essential for the accurate measurement of turbine parameters (speed, temperature, pressure) and the precise execution of control commands, directly impacting the safe, efficient, and reliable operation of the entire turbine unit.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

GE IS215WEPAH2BB

|

|

Manufacturer

|

GE Power (formerly GE Energy, part of GE Vernova)

|

|

System Platform

|

GE Mark VIe Turbine Control System

|

|

Product Type

|

I/O Termination Board / Field Interface Board

|

|

Compatible I/O Pack

|

Designed to interface with specific Mark VIe I/O packs (e.g., IS215WEPAH2A — Analog Input Pack)

|

|

Primary Function

|

Field wiring termination, signal conditioning, and distribution for turbine I/O

|

|

Connectors

|

High-density, multi-pin connectors for mating with I/O packs (e.g., DIN 41612 type) and screw terminal blocks or sub-D connectors for field wiring

|

|

Channel Types

|

Supports a mix of signal types routed through it, typically including analog inputs (TC, RTD, 4-20mA), analog outputs, discrete inputs (24/48/125V DC), discrete outputs (relay or triac), and possibly speed sensing inputs.

|

|

Isolation/Barrier

|

Provides galvanic isolation and/or incorporates signal conditioning components (resistors, fuses) as required by the connected I/O pack and field devices.

|

|

Diagnostics

|

Status LEDs (if populated) for power and communication. Fault diagnosis is primarily handled by the connected I/O pack and controller.

|

|

Mounting

|

Designed for installation in a standard Mark VIe rack or panel assembly.

|

|

Environmental Rating

|

Designed for operation in a controlled turbine enclosure environment (typically 0-60°C).

|

|

Agency Approvals

|

Complies with GE specifications and relevant industrial standards for turbine controls.

|

Key Features and Advantages

The GE IS215WEPAH2BB is engineered for robust signal interfacing and maximum system reliability in critical turbine applications. Its primary advantage is providing a secure, organized, and high-integrity termination point for all field cabling. The use of robust screw terminal blocks or mil-spec connectors ensures reliable connections that can withstand the vibration and thermal cycling inherent in power generation environments. This design prevents loose wires and intermittent connections that could lead to erroneous readings or control failures.

Modularity and ease of maintenance are central to its design philosophy. The termination board is physically separate from the active electronics (the I/O pack). This allows technicians to replace a faulty I/O pack quickly by simply unplugging it from the IS215WEPAH2BB, without the need to unscrew or re-terminate any field wires. This dramatically reduces mean time to repair (MTTR) during critical outages. The board often includes grouped and labeled terminals corresponding to specific I/O channels (e.g., AI1+, AI1-), which simplifies wiring, checkout, and troubleshooting.

Signal integrity and system protection are built-in. The board incorporates necessary passive components, such as fuses, resistors for current loop power, and jumpers for configuration (e.g., selecting 2-wire vs. 4-wire RTD, sourcing vs. sinking inputs). These components provide basic protection against wiring errors and help condition signals before they reach the sensitive electronics of the I/O pack. By centralizing these functions on a dedicated termination board, the system design becomes cleaner, more standardized, and easier to validate, which is paramount for safety-critical turbine control systems. The GE IS215WEPAH2BB, therefore, is not just a passive wiring hub but an active participant in ensuring the overall accuracy, availability, and safety of the turbine control loop.

Application Areas

The GE IS215WEPAH2BB has one primary and highly specific application: as the field interface component within a GE Mark VIe gas turbine, steam turbine, or combined-cycle power plant control system. Its use is integral to the operation of the turbine across all phases:

-

Starting & Sequencing: It interfaces with start-up devices (lube oil pump status, turning gear position), ignition system controls, and valve limit switches.

-

Speed & Load Control: It brings in critical feedback signals such as turbine speed (from magnetic pickups or proximity probes), compressor inlet temperature and pressure, exhaust temperature (via thermocouples), and generator power output. It also sends control signals to fuel control valves and inlet guide vanes.

-

Protection & Safety: It connects to critical safety sensors including overspeed probes, vibration monitors, flame detectors, and high-temperature thermocouples. The integrity of these connections, ensured by this board, is vital for triggering safe shutdowns.

-

Auxiliary System Monitoring: It provides I/O for lube oil temperature and pressure, hydraulic fluid pressure, and cooling fan status.

In essence, every measurable parameter and every controllable device on or around the turbine that interacts with the Mark VIe control system likely passes through a termination board like the IS215WEPAH2BB. It is a cornerstone of the control system’s physical layer in virtually all modern GE heavy-duty turbine installations worldwide.

Related Products

-

GE IS215WEPAH2A: The analog input I/O pack (electronic module) that plugs directly into the IS215WEPAH2BB termination board to provide the actual signal conversion and processing.

-

Other Mark VIe I/O Packs (e.g., IS215WDPAH, IS215VCMAH): Digital input/output packs and communication modules that have their own corresponding termination boards.

-

GE Mark VIe Controller (e.g., IS200/IS215 series): The main turbine controller (TMR or Simplex) that processes data from and sends commands to the I/O packs connected to termination boards.

-

GE EX2100e / EX2100e Excitation Controller: The generator excitation system which interfaces with the Mark VIe for turbine-generator control.

-

GE Speedtronic™ ToolboxST / Mark VIe Engineering Tools: The software suite used to configure, monitor, and diagnose the entire Mark VIe system, including the I/O channels mapped through termination boards.

-

GE Turbine-specific Sensors & Actuators: The field devices (e.g., Bently Nevada vibration probes, thermocouples, servo valves) whose wires terminate on the IS215WEPAH2BB.

-

GE Mark VIe Rack and Backplane: The physical enclosure and communication infrastructure that houses the controllers, I/O packs, and termination boards.

-

GE Replacement Terminal Blocks / Connectors: Spare parts for the specific terminal blocks used on the WEPAH2BB board.

Reviews

There are no reviews yet.