Description

Product Overview

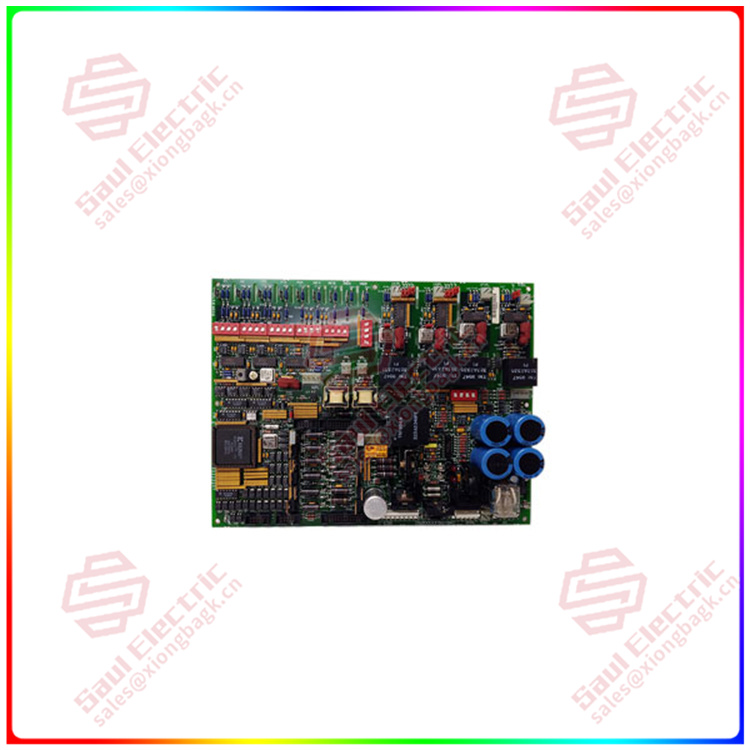

The GE DS200DCFBG2BNC (Material Part Number MRP433745) is a critical circuit board assembly within the General Electric (GE) Mark V gas/steam turbine control system. Specifically, it is a Digital Control Feedback Interface Board or Signal Conditioning/Distribution Board. This printed circuit board (PCB) is an integral component of the complex analog and digital signal routing network inside a Mark V control cabinet. Its primary function is to serve as an interface between various sensor signals (e.g., temperature, pressure, vibration) and the main control processors, providing signal conditioning, isolation, filtering, and distribution. The board is populated with operational amplifiers, comparators, digital isolators, resistor networks, and other passive components designed to process low-level signals from field transmitters. It converts these raw signals into clean, stable levels suitable for transmission to corresponding I/O boards (such as DCOI or DACA cards) or directly to processor boards. The suffix «BNC» indicates the board is equipped with BNC connectors, which are typically used for high-frequency or coaxial signals, such as those from eddy current proximity probes (for speed/vibration measurement).

This board is a fundamental component of the Mark V Speedtronic™ control system architecture, a platform renowned for its reliability in managing large, critical rotating equipment. The DS200DCFBG2BNC does not execute control logic itself but ensures the integrity and quality of the measurement data upon which that logic depends. For maintenance technicians and engineers supporting GE turbine installations, this board represents a repairable/replaceable unit (FRU) that, when faulty, can cause specific sensor channels to fail or read inaccurately, potentially leading to erroneous control actions or alarms. Its value lies in its role as a reliable signal integrity gatekeeper within a high-performance, mission-critical control system.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

GE DS200DCFBG2BNC (MRP433745)

|

|

Manufacturer

|

General Electric (GE)

|

|

System Platform

|

Mark V Speedtronic™ Turbine Control System

|

|

Product Type

|

Signal Conditioning / Interface Board (PCB Assembly)

|

|

Primary Function

|

Analog signal conditioning, isolation, and distribution for feedback sensors (e.g., speed, vibration, temperature).

|

|

Key Components

|

Operational amplifiers, instrumentation amplifiers, voltage comparators, opto-isolators, precision resistors/capacitors, BNC connectors.

|

|

Input Signal Types

|

Conditions various analog signals, likely including: low-level voltage/current from speed pickups, vibration probes (eddy current), temperature sensor signals (e.g., from RTDs or thermocouples via transmitters).

|

|

Connectors

|

Features BNC coaxial connectors for input/output, suitable for shielded, high-integrity signal transmission common in vibration and speed monitoring.

|

|

Form Factor

|

Standard Mark V system printed circuit board designed for installation in a specific slot within a Mark V I/O or termination chassis.

|

|

Power Requirement

|

Receives low-voltage DC power (e.g., ±15V, +5V) from the Mark V backplane or an associated power supply board.

|

|

Isolation

|

Provides galvanic isolation between field-side sensor connections and the system-side control electronics to prevent ground loops and noise interference.

|

|

Diagnostics

|

Limited onboard active diagnostics; health is typically inferred from the processed signal’s validity at the receiving I/O or processor module.

|

|

Operating Temperature

|

Designed for operation within the controlled environment of a Mark V cabinet (typically 0-60°C).

|

|

Agency Standards

|

Complies with the electrical and safety standards of the overall Mark V system.

|

Key Features and Advantages

GE DS200DCFBG2BNC MRP433745 is defined by its application-specific design and role in ensuring signal integrity. Its primary advantage is providing tailored signal conditioning for critical turbine feedback signals. The circuitry is specifically designed to amplify weak signals, filter out electrical noise inherent in industrial environments, and provide proper impedance matching. The use of BNC connectors ensures secure, shielded connections for sensitive signals like those from magnetic pickups or proximity probes, which are vital for accurate speed and vibration measurement—key parameters for turbine protection and control.

Robust isolation and reliability are engineered into its core function. The board incorporates isolation barriers (opto-isolators or transformer isolation) that break ground loops between the turbine casing/sensors and the sensitive control system electronics. This prevents transient voltages and common-mode noise from disrupting control logic or damaging downstream components. As a factory-designed and tested component of the Mark V system, it offers guaranteed compatibility and performance, ensuring that the control system receives sensor data that accurately reflects the physical state of the turbine.

Serviceability and role in system maintenance are practical benefits. The board is a Field Replaceable Unit (FRU), allowing for relatively straightforward troubleshooting and repair. When a specific sensor channel exhibits problems, the DS200DCFBG2BNC is a likely suspect after checking the sensor and cabling itself. Replacing this board can restore multiple signal paths. For support personnel, having access to the correct spare part number (MRP433745) is crucial for minimizing turbine downtime. While it contains no programmable intelligence, its proper function is essential for the higher-level control and protection algorithms to operate correctly, making it a critical, albeit often overlooked, component in the reliability chain.

Application Areas

The GE DS200DCFBG2BNC board is exclusively used within GE Mark V turbine control systems.

Its application is dedicated to the conditioning and interfacing of critical feedback signals for gas turbines and steam turbines controlled by the Mark V system. This includes:

-

Speed Signal Conditioning: Processing raw AC signals from magnetic speed pickups on the turbine shaft before they are sent to the overspeed protection and control circuits.

-

Vibration Monitoring Interface: Conditioning signals from eddy current vibration probes for input to dedicated vibration monitor cards or the main controller for protection.

-

Key Phase/Other Sensor Interface: Handling timing or reference signals used for synchronization and analysis.

The board is found in the I/O compartment of Mark V control cabinets in power plants, mechanical drive applications, and offshore platforms worldwide. Essentially, wherever a GE Frame 5, 6, 7, 9 or other turbine utilizing a Mark V controller operates, boards like the DS200DCFBG2BNC are at work, ensuring the raw «nervous system» signals from the turbine are accurately conveyed to its digital «brain.»

Related Products

-

GE Mark V Controller (e.g., <CPU Board>): The central processor that uses the conditioned signals from this board.

-

GE Mark V I/O Boards (e.g., DS200 DCOI, DS200 DACA): Digital and analog I/O cards that may receive the processed signals from the DCFBG2BNC.

-

Field Sensors: Magnetic pickups, eddy current proximity probes, accelerometers whose signals are conditioned by this board.

-

Mark V Power Supply Boards: Provide the operating power to the DCFBG2BNC.

-

Mark V Backplane/Chassis: The hardware framework that houses and interconnects all boards, including the DCFBG2BNC.

-

GE Speedtronic™ Mark VI, VIe, or ControlST: Successor turbine control platforms to the Mark V, with different, more integrated component designs.

Reviews

There are no reviews yet.