Description

Product Overview

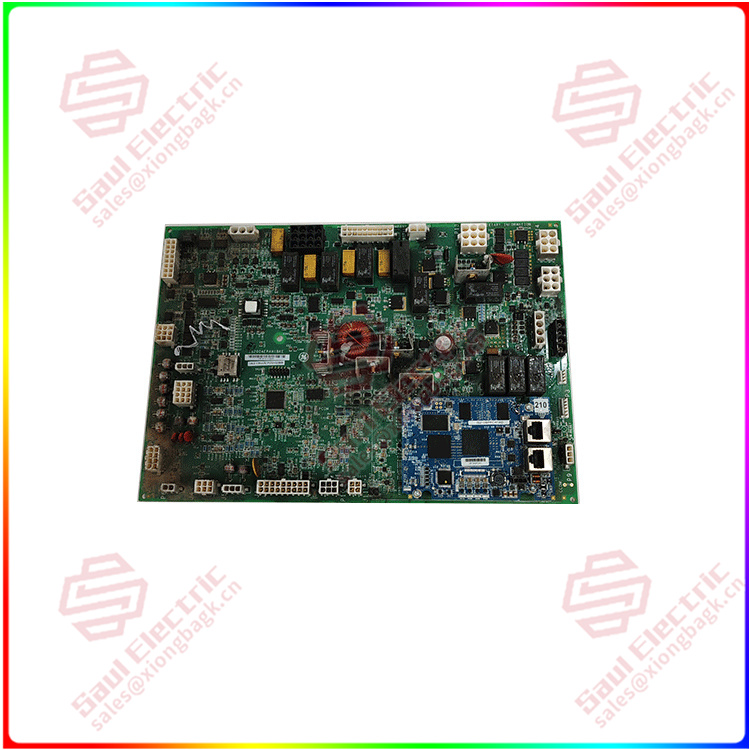

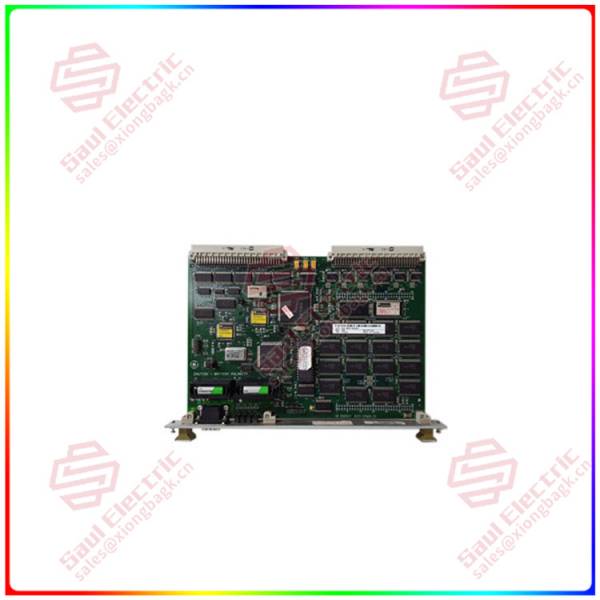

The GE IS200AEPCH1ABC is a critical Analog Input Module from the General Electric (GE) Mark VI gas/steam turbine control system, part of the renowned Speedtronic™ series. This specific module, the AEPC model, is a high-performance, isolated input module designed for the acquisition and conditioning of analog process signals. Its primary function is to interface with a variety of field transmitters and sensors—such as 4-20 mA current loop transmitters, thermocouples, RTDs, and DC voltage signals—and convert these analog signals into high-resolution digital values for use by the Mark VI’s main processors. The module performs essential signal conditioning tasks, including filtering, scaling, and isolation, to ensure accurate and reliable data acquisition in the electrically noisy environment of a power plant. The suffix

H1ABCindicates the specific hardware revision, channel configuration, and I/O characteristics.The value of the GE IS200AEPCH1ABC lies in its precision, robustness, and seamless integration within the Mark VI I/O architecture. It serves as the vital sensory interface for critical turbine parameters like bearing metal temperatures, lube oil pressure, compressor inlet temperature, exhaust temperature, and other process variables essential for control, sequencing, and protection. Each channel on the module provides high-grade galvanic isolation to protect the sensitive control system from field-side transients and ground loops. The module is also equipped with diagnostics to detect sensor failures, such as open thermocouples or broken RTD wires. For turbine engineers and control technicians, the reliable operation of the AEPC module is paramount for maintaining safe operating limits, enabling efficient control loops, and providing the data necessary for condition monitoring and historical trending of the turbine’s health.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

GE IS200AEPCH1ABC

|

|

Manufacturer

|

General Electric (GE)

|

|

System Platform

|

Mark VI Speedtronic™ Turbine Control System

|

|

Product Type

|

Analog Input Module (Isolated, High Density)

|

|

Input Channels

|

Typically 8 or 16 isolated analog input channels per module (specific to AEPC-H1ABC variant).

|

|

Input Signal Types

|

Configurable per channel for:

|

Key Features and Advantages

GE IS200AEPCH1ABC excels through its versatility, accuracy, and built-in intelligence. A primary advantage is its per-channel configurability; each input can be independently set up for a different signal type (mA, V, TC, RTD) via software configuration. This flexibility allows a single module type to serve a wide range of measurement points in a turbine control cabinet, simplifying spares inventory. The module’s high channel density combined with high-grade signal isolation ensures that multiple signals can be acquired accurately without crosstalk or interference, which is critical for reliable control and protection.

Advanced diagnostics and signal integrity are cornerstones of its design. Beyond simple measurement, the AEPC module actively monitors the health of the connected sensors. Its ability to detect an open thermocouple or RTD is crucial for safety, as a failed temperature sensor could mask a dangerous over-temperature condition. The diagnostic alarms are reported directly to the Mark VI controller, enabling immediate operator awareness. The module’s design ensures excellent noise rejection and stable operation in the presence of the strong electromagnetic interference common near large motors and generators.

Seamless integration and reliability within the Mark VI ecosystem are key benefits. As a native Mark VI component, it is guaranteed to be compatible with the backplane, controller, and configuration tools (ToolboxST software). Its modular, hot-swappable design (when used in conjunction with proper system procedures) allows for replacement without shutting down the entire I/O network. For system designers and maintenance personnel, the IS200AEPCH1ABC provides a trusted, high-performance solution for acquiring critical analog data, forming a reliable foundation for the turbine’s monitoring, control, and protection systems, thereby directly contributing to unit availability and safety.

Application Areas

The GE IS200AEPCH1ABC analog input module is deployed within GE Mark VI turbine control systems across the power generation and large mechanical drive sectors.

Its application is dedicated to measuring critical process variables for gas and steam turbine control and protection, including:

-

Temperatures: Bearing metal temperatures, lube oil temperature, compressor discharge temperature, turbine exhaust temperature, winding temperatures.

-

Pressures: Lube oil pressure, fuel gas pressure, hydraulic pressure, compressor inlet/discharge pressure.

-

Flows and Levels: (Via 4-20 mA transmitters) Fuel flow, coolant flow, tank levels.

-

Vibration and Position: (Conditioned signals from monitoring systems) as 4-20 mA or voltage inputs.

Essentially, any continuous process variable on a turbine that needs to be monitored for control logic, displayed to an operator, used in protection algorithms, or logged for performance analysis is a candidate for measurement by an AEPC module. It is a fundamental component in the sensory layer of the Mark VI system.

Related Products

-

GE Mark VI Controller (e.g., IS200/IS215 series processors): The main processor that reads data from the AEPC module.

-

GE Mark VI I/O Pack Carriers/Backplanes: The hardware that houses the AEPC and other I/O modules.

-

GE Mark VI Digital I/O Modules (e.g., IS200 series): For handling discrete (on/off) signals.

-

Field Sensors and Transmitters: The thermocouples, RTDs, and 4-20 mA transmitters that connect to the AEPC inputs.

-

Terminal Boards/Blocks: The interface between field wiring and the AEPC module’s connector.

-

GE ToolboxST Software: The configuration, programming, and diagnostic environment for the Mark VI system, used to set up the AEPC module’s channel parameters, scaling, and alarms.

Reviews

There are no reviews yet.