Description

Product Overview

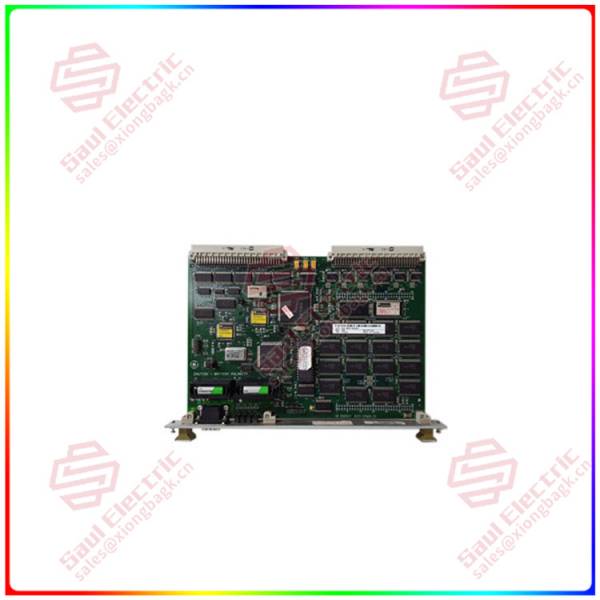

The GE IS200WREAS1ADB is a critical Communication and Control Module from the General Electric (GE) Mark VI Speedtronic™ gas/steam turbine control system, specifically a Wheel and Rack Ethernet Adapter or network interface module. The designation «WREA» strongly suggests it functions as a Wheel/Rack Ethernet Adapter, serving as a specialized Ethernet Communication Interface for the Mark VI system. Its primary function is to provide high-speed, deterministic Ethernet connectivity between the Mark VI controller and other GE system components, external networks, or plant-wide control systems. It acts as a gateway, translating the Mark VI’s internal VCMI (Versatile Controller Module Interface) or other proprietary backplane communication into standard IEEE 802.3 Ethernet frames. This enables data exchange for control, monitoring, historian data collection, and remote engineering access.

The value of the GE IS200WREAS1ADB lies in its ability to seamlessly integrate the Mark VI controller into modern networked plant environments. It provides a standardized, high-bandwidth communication path essential for real-time turbine data acquisition, remote operation from a plant DCS/SCADA, firmware updates, and integration with higher-level systems like GE’s ToolboxST software for engineering and diagnostics. The module ensures reliable, time-sensitive communication critical for coordinated control in multi-turbine plants (like combined-cycle) and for condition monitoring systems. For turbine engineers and plant IT/OT staff, the proper operation of the WREA module is fundamental for achieving centralized visibility, efficient maintenance, and optimal performance of the turbine, bridging the gap between the specialized turbine controller and the broader industrial IT infrastructure.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

GE IS200WREAS1ADB

|

|

Manufacturer

|

General Electric (GE)

|

|

System Platform

|

Mark VI Speedtronic™ Turbine Control System

|

|

Product Type

|

Ethernet Communication Interface Module (Wheel/Rack Adapter)

|

|

Primary Function

|

Provides Ethernet connectivity for the Mark VI controller; acts as a network gateway.

|

|

Ethernet Interface

|

Typically features one or more 10/100Base-T or 100Base-FX Ethernet ports (RJ-45 or fiber). The «S1ADB» suffix may specify the media type (e.g., copper).

|

|

Network Protocols

|

Supports industry-standard protocols for control and configuration, such as:

|

Key Features and Advantages

GE IS200WREAS1ADB excels as a high-performance network gateway for turbine control. Its primary advantage is providing a standardized, high-speed Ethernet link that unlocks the connectivity of the Mark VI system. This allows for real-time data streaming to HMIs and historians, remote monitoring from central control rooms, and seamless coordination in multi-unit power plants. Support for protocols like Ethernet Global Data (EGD) enables deterministic, low-latency data exchange between multiple turbines and auxiliary controllers, which is critical for fast load sharing and protection schemes in combined-cycle applications.

Enhanced diagnostics and remote accessibility are integral to its value. The Ethernet connection facilitates powerful remote diagnostics and configuration via ToolboxST. Engineers can connect to the turbine controller from anywhere on the plant network (or securely via VPN) to monitor performance, troubleshoot issues, update firmware, and download controller logs without being physically at the turbine skid. This capability dramatically improves maintenance efficiency and reduces mean time to repair (MTTR).

Future-proofing and system integration are key benefits. The use of standard Ethernet ensures compatibility with modern plant networking infrastructure and eases integration with supervisory systems (DCS, SCADA) and enterprise-level asset performance management (APM) platforms. The module’s reliability and deterministic performance are engineered for 24/7 operation in critical control applications. For system architects, the WREAS1ADB transforms the Mark VI from a standalone controller into a networked node within the Industrial Internet of Things (IIoT), enabling data-driven decision-making, predictive maintenance, and optimized plant performance.

Application Areas

The GE IS200WREAS1ADB is a core communication component in GE Mark VI turbine control systems across the power generation and mechanical drive sectors.

Its application is essential for:

-

Combined-Cycle Power Plants (CCPP): Enabling high-speed data exchange between gas turbine, steam turbine, and balance of plant controllers for coordinated control and optimization.

-

Multi-Turbine Power Plants: Facilitating peer-to-peer communication for load dispatch and grid support functions.

-

Remote Monitoring and Diagnostics: Providing the communication path for OEM (GE) or owner-operator remote monitoring centers to access turbine data for performance analysis and predictive maintenance.

-

Plant DCS/SCADA Integration: Serving as the primary data gateway for the plant’s distributed control system to monitor and supervise the turbine.

-

Standalone Turbine Control: Providing network access for the local HMI, engineering workstation, and data historian.

Essentially, any Mark VI-controlled turbine that requires connectivity beyond its local I/O—for operation, monitoring, or maintenance—relies on a WREA or similar Ethernet interface module.

Related Products

-

GE Mark VI Controller (e.g., IS200/IS215 processors): The main controller that the WREA module provides network access for.

-

GE ToolboxST Software: The engineering and diagnostic software that communicates with the controller via this Ethernet module.

-

Plant Network Switches: The industrial Ethernet switches to which the WREA module connects.

-

HMIs and SCADA Systems: The operator interfaces and supervisory systems that display data acquired via the WREA.

-

Mark Vie or other Controller Communication Modules: For different network types (e.g., Profibus, Genius).

-

Network Cables (Copper/Fiber): The physical media connecting the module to the network.

Reviews

There are no reviews yet.