Description

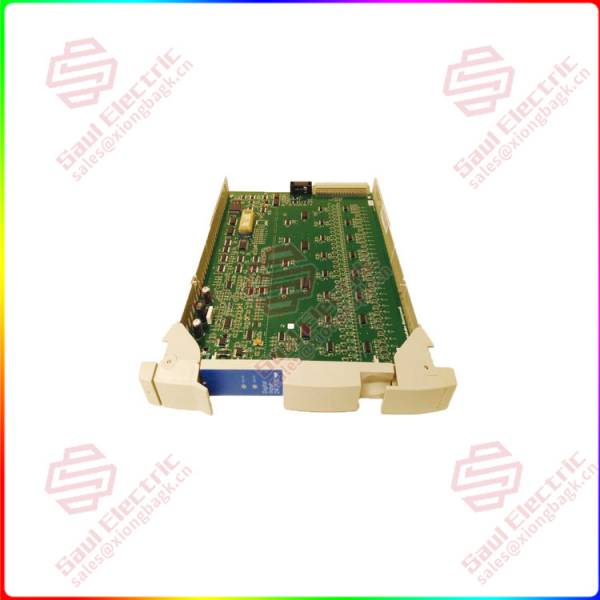

HONEYWELL HCIX15-TE-FA-NC-C — Technical Overview

Product: HCIX15-TE-FA-NC-C, High-Capacity Input Module for Safety Systems

Manufacturer: Honeywell International Inc.

Primary Application: A high-density, fault-tolerant digital input module for Honeywell Safety Manager and Experion HS Safety Systems. It is designed for Safety Instrumented Systems (SIS) to reliably monitor the status of critical field devices (e.g., emergency stop buttons, pressure safety switches, flame detectors) in process industries.

1. Core Overview & Positioning

The HCIX15-TE-FA-NC-C is a specialized component of Honeywell’s High-Performance Process (HPP) Safety System family. It belongs to the HCI (High-Capacity Input) series and is engineered for SIL 3 (Safety Integrity Level 3) applications as per IEC 61508/61511 standards.

Key Philosophy: This module provides a reliable, fault-tolerant interface between the safety logic solver and field-mounted safety switches. Its design focuses on fail-safe behavior, diagnostic coverage, and high availability to ensure that dangerous failures in the input circuit are detected and lead to a safe state.

2. Key Features & Functions

-

High-Density Input: Provides a large number of digital input channels (typically 16 or 32) in a single module slot, optimizing cabinet space.

-

Fault-Tolerant (FA) Architecture: The «-FA» suffix indicates a Fail-Adaptive or advanced fault-tolerant design. It employs redundant internal circuits and continuous diagnostics to tolerate internal faults without causing a spurious trip or losing the safety function.

-

DEH (Dual Electronic Hook-up): A key feature of Honeywell safety I/O. Each field device is wired to two independent input circuits on the same module. This allows the safety logic solver to perform on-line comparison of the two signals, detecting discrepancies that indicate a wiring or channel fault.

-

Comprehensive Diagnostics:

-

Continuous monitoring for field wire breaks (open circuit detection).

-

Monitoring for cross-wiring or short circuits to voltage.

-

Internal processor and memory diagnostics.

-

-

SIL 3 Capable: When used within a certified Safety Manager architecture and with proper application engineering, it contributes to achieving SIL 3 safety loops.

-

Hot Swappable: Supports online module replacement in a properly configured redundant system, minimizing downtime.

3. Common Technical Specifications

-

Input Type: Dry Contact or Namur (proximity switch) inputs. Designed for passive contacts.

-

Number of Channels: Likely 16 or 32 independent, dual-channel (DEH) monitored inputs.

-

Voltage: The field side is typically powered by the safety system’s isolated SIS power supply (often 24V DC).

-

Diagnostics: Open circuit, short circuit, and DEH comparison diagnostics.

-

Communication: Connects to the Safety Manager controller via a high-integrity internal bus.

-

Module Format: A single-slot module that installs into a Honeywell C Series or HCI Series I/O rack.

4. System Integration & Safety Context

-

Role: Serves as the primary sensing interface for a Safety Instrumented Function (SIF). For example, it would be the input for a High Pressure Trip SIF:

-

A pressure safety switch (normally closed) in the field is wired via the Termination Module (TM) to the two channels of one point on the HCIX15.

-

The module constantly reads and compares both signals.

-

If the pressure goes high, the switch opens. Both channels read «open,» and the Safety Manager logic solver initiates the programmed safety action (e.g., close a valve).

-

If one channel fails or a wire breaks, the mismatch is detected, and a diagnostic alarm is raised without causing an immediate trip (thanks to FA architecture), allowing for planned maintenance.

-

-

Configuration: The module is configured within the overall safety application logic using Honeywell’s Safety Builder software.

5. Typical Applications

Used in any process industry where SIL-rated safety monitoring is required:

-

Emergency Shutdown (ESD) Systems: Monitoring ESD pushbuttons, level switches, pressure switches.

-

Fire & Gas (F&G) Systems: Monitoring flame detector or gas detector fault and alarm contacts.

-

Burner Management Systems (BMS): Monitoring flame scanner and valve limit switch status.

-

Turbomachinery Control: Monitoring overspeed device contacts, vibration switch contacts.

Reviews

There are no reviews yet.