Description

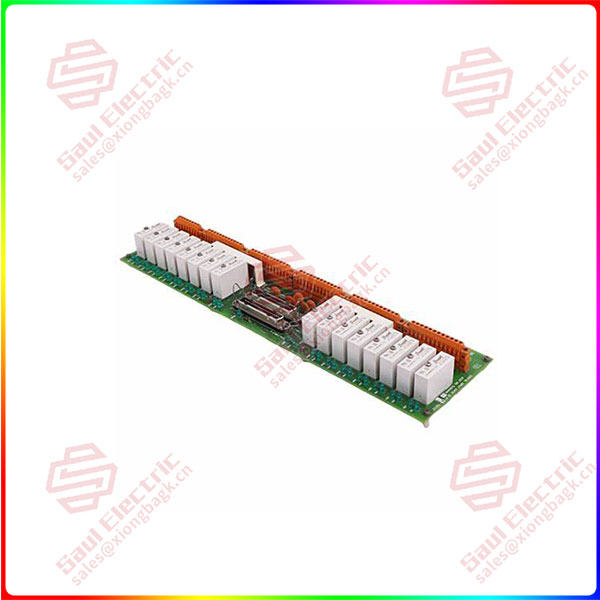

HONEYWELL FC-TSKUNI-1624 — Universal Field Controller

Product: FC-TSKUNI-1624, Universal Field Controller Module

Manufacturer: Honeywell International Inc.

Product Line: Excel 5000 / WEBs Building Management System (BMS)

Primary Application: A universal, programmable field controller designed for the monitoring and control of HVAC equipment, lighting, and other building systems in commercial, industrial, and institutional facilities. It acts as a local intelligence unit within a distributed building automation network.

1. Core Overview & Positioning

The Honeywell FC-TSKUNI-1624 is a flexible, stand-alone controller from Honeywell’s Excel 5000 family, now also integrated into the Niagara Framework-based WEBs (Wireless Enabled Building Solutions) platform. The «UNI» in the model indicates its universal nature, capable of handling a wide variety of inputs and outputs through configurable points.

Key Philosophy: It provides a powerful, localized processing node that can execute complex control sequences independently, reducing the load on central servers and increasing system reliability. It connects to a supervisory network (like WEBs-Nx) to report data and receive schedules/commands.

2. Key Features & Functions

-

Flexible, Configurable I/O: The core feature is its universal input/output points. These points are not hardware-fixed; they are software-configurable in the field to act as:

-

Analog Inputs (AI): For 0-10V, 0-20mA, 4-20mA, or resistance (RTD, potentiometer) signals from sensors (temperature, humidity, pressure, CO₂).

-

Digital Inputs (DI): For contact closures (dry contacts) from switches, flow switches, or status contacts.

-

Analog Outputs (AO): For 0-10V or 4-20mA signals to control devices like valve actuators, variable frequency drives (VFDs), or damper motors.

-

Digital Outputs (DO): Triac or relay outputs to start/stop motors, open/close valves, or energize alarms.

-

-

Powerful Local Processing: Equipped with a 32-bit microprocessor capable of running complex control applications, PID loops, and custom logic programs written in Honeywell Control Language (HCL) or standard programming languages within the Niagara Framework.

-

Standalone Operation: Can maintain and execute its control program even if communication to the central supervisor is lost, ensuring continued building operation.

-

Comprehensive Communication:

-

C-Bus (Controller Bus): Honeywell’s proprietary, high-speed peer-to-peer network for connecting multiple Excel 5000 controllers for coordinated control (e.g., chiller plant sequencing).

-

LON (LonWorks) or BACnet: Often includes a port for integration into open protocol BMS networks.

-

Supervisor Network: Connects to a WEBs Supervisor or Enterprise Server via Ethernet (TCP/IP) or serial for monitoring, data logging, and global scheduling.

-

-

Non-Volatile Memory: Retains its application program and configuration during power loss.

3. Model Number & Technical Specifications

Common/Inferred Technical Specifications:

-

Processor: 32-bit RISC processor.

-

Memory: Flash memory for application storage, RAM for runtime.

-

I/O Points: A mix of universal configurable points (e.g., 6 UI/UC) and possibly dedicated digital inputs/outputs. Each universal point is individually software-configured for its function (AI, DI, AO, DO).

-

Power Supply: 24 VAC or 24 VDC (typically, as standard for building automation).

-

Operating Temperature: 0°C to 50°C (32°F to 122°F).

-

Communication Ports:

-

C-Bus Port: For peer networking with other Honeywell controllers.

-

Service Port: RS-232 for direct laptop connection (using a USB converter).

-

Network Port: Likely an Ethernet (RJ-45) port for TCP/IP connection to the BMS network.

-

-

Mounting: DIN-rail mountable enclosure.

4. System Integration & Engineering

-

Role in BMS Hierarchy: It is a field-level controller. It interfaces directly with sensors and actuators in the mechanical room or on the equipment. It reports data to and can be overridden by a supervisory-level workstation (WEBs Supervisor).

-

Engineering Software: Programmed and configured using:

-

Honeywell CARE (Computer Aided Regulation Engineering): The traditional software for Excel 5000 controllers.

-

Niagara Workbench: The modern framework for WEBs systems, where the controller appears as a «station» to be configured.

-

-

Configuration Steps:

-

Define the physical hardware (I/O points, their types, and scaling).

-

Create control applications using function block diagrams, HCL, or other Niagara programming tools.

-

Define alarms, trends, and schedules.

-

Bind controller points to the graphics and database on the supervisor.

-

-

Typical Integration: Used to control complex HVAC equipment like Air Handling Units (AHUs), Fan Coil Units (FCUs), heat pumps, or small packaged rooftop units.

5. Typical Applications

-

Air Handling Unit (AHU) Control: Managing fans, heating/cooling coils, humidifiers, and dampers with sequences for morning warm-up, economizer operation, and supply air temperature reset.

-

Variable Air Volume (VAV) Box Control: (When configured as a zone controller).

-

Chiller, Boiler, or Cooling Tower Plant Sequencing: Multiple FC-TSKUNI controllers can communicate via C-Bus to sequence multiple chillers based on load.

-

Lighting Control: For scheduling and occupancy-based control of lighting circuits.

-

Energy Management: Implementing demand limiting, load shedding, and optimal start/stop routines.

Reviews

There are no reviews yet.