Description

Product Overview

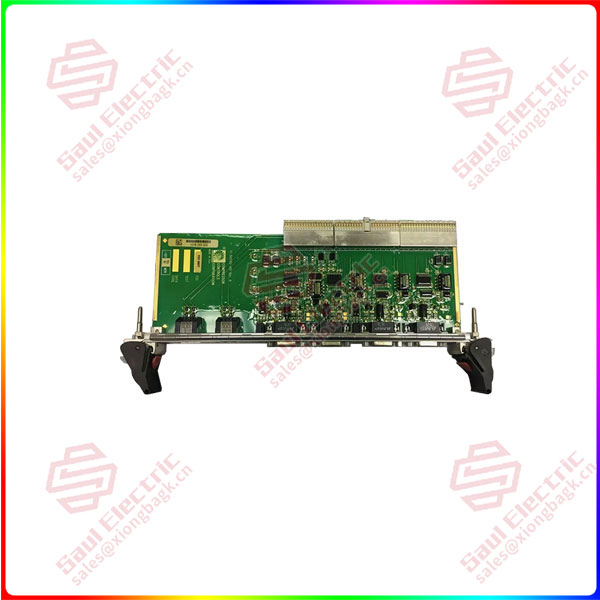

The CCC TMPU-1002 is a specialized Temperature Measurement and Processing Unit, likely designed for use in critical process control, power generation, or industrial automation applications. The «CCC» acronym may stand for the manufacturer (e.g., potentially associated with a company like Curtiss-Wright, Control Concepts Corporation, or another specialized OEM), and «TMPU» clearly denotes its primary function. This unit is an intelligent, rack-mountable electronic assembly whose core purpose is to acquire, condition, isolate, and process signals from multiple temperature sensors—most commonly Thermocouples (TCs) and Resistance Temperature Detectors (RTDs). It acts as a high-density, remote temperature monitoring subsystem, converting low-level sensor signals into standardized, high-integrity digital or analog outputs for use by a central Distributed Control System (DCS), Programmable Logic Controller (PLC), or data acquisition system.

The value of the CCC TMPU-1002 lies in its precision, channel density, and signal integrity management. In applications like gas or steam turbine monitoring, reactor temperature profiling, or multi-zone furnace control, there is a need to monitor dozens or hundreds of temperature points reliably. The TMPU consolidates this function into a single, managed unit. It provides essential features such as cold-junction compensation for thermocouples, excitation current for RTDs, galvanic isolation between channels to prevent ground loops, linearization, and alarm generation. For system engineers, deploying the TMPU-1002 simplifies cabinet design, reduces wiring complexity to the main controller, and provides a reliable, maintainable solution for critical temperature monitoring with built-in diagnostics.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

CCC TMPU-1002

|

|

Manufacturer

|

CCC (Specific manufacturer identification needed, e.g., Curtiss-Wright Controls)

|

|

Product Type

|

Intelligent Temperature Measurement & Processing Unit

|

|

Input Channels

|

High-density input, typically supporting 16, 32, or 64 channels of temperature sensor inputs.

|

|

Supported Sensor Types

|

Thermocouples (Types J, K, T, E, R, S, B, N) and RTDs (2-wire, 3-wire, 4-wire Pt100, Pt1000, Cu10, Ni120). Configurable per channel.

|

|

Measurement Accuracy

|

High accuracy, typically ±0.1% of reading or ±0.5°C for RTDs, and similar for TCs with cold-junction compensation.

|

|

Isolation

|

Channel-to-channel isolation and channel-to-system isolation, typically 250V AC or higher, to eliminate ground loops and noise.

|

|

Input Scanning Rate

|

Configurable scan rate for all channels, typically in the range of 10 to 100 channels per second.

|

|

Signal Processing

|

Performs linearization, scaling, digital filtering, and engineering unit conversion (°C/°F).

|

|

Alarms

|

Programmable high/high-high and low/low-low alarms per channel with time delays.

|

|

Output Interface

|

Provides processed data to a host system via analog outputs (4-20mA) or, more commonly, digital communication such as:

|

Key Features and Advantages

CCC TMPU-1002 excels as a centralized, intelligent temperature acquisition hub. Its primary advantage is consolidating many temperature points into a single, smart device, dramatically reducing the number of individual signal conditioners and I/O cards required in the main control system. This saves cost, panel space, and wiring complexity. The unit’s per-channel configurability allows a mix of different thermocouple and RTD types to be connected to the same unit, providing exceptional application flexibility.

Superior signal integrity and diagnostics are engineered into its design. The high-grade channel isolation prevents noise coupling and ground loop issues, which are common problems when measuring low-voltage TC signals in industrial environments. Advanced features like RTD lead resistance compensation (for 3-wire and 4-wire connections) ensure accurate measurement regardless of cable length. The integrated sensor diagnostics (open circuit detection) provide immediate warning of a failed sensor, enabling proactive maintenance and preventing a loss of critical process data.

Network readiness and ease of integration are key benefits. By offering standard industrial communication protocols like Modbus TCP/IP or Profibus, the TMPU-1002 can easily interface with virtually any modern DCS, SCADA, or PLC system. It acts as a slave device, providing a clean, pre-processed data stream to the host. This simplifies system integration and allows for remote configuration and monitoring. For maintenance personnel, the centralized design means all temperature-related I/O is in one location, simplifying troubleshooting and calibration. In summary, it transforms the complex task of multi-point temperature monitoring into a streamlined, reliable, and data-rich subsystem.

Application Areas

The CCC TMPU-1002 is designed for applications requiring high-density, reliable temperature monitoring, often in mission-critical or harsh environments.

Typical applications include:

-

Power Generation: Monitoring bearing metal temperatures, winding temperatures, and exhaust gas temperatures on gas/steam turbines, generators, and large motors.

-

Nuclear Power Plants: For safety-related and non-safety-related temperature monitoring, where its certifications are crucial.

-

Process Industries: Reactor temperature profiling in chemical/petrochemical plants, multi-zone temperature control in furnaces and kilns.

-

Automated Test Stands: For aerospace and automotive component testing where numerous temperature points are logged.

-

Industrial Machinery: Monitoring temperatures on large compressors, pumps, and gearboxes.

Essentially, it is used wherever there is a need to accurately and reliably monitor a large number of temperature points from a centralized location, particularly where signal integrity, isolation, and advanced diagnostics are valued.

Related Products

-

Temperature Sensors: The TCs and RTDs that connect to the TMPU inputs.

-

Host Control System (DCS/PLC/SCADA): The system that receives data from the TMPU via its communication interface.

-

Communication Gateways/Converters: If protocol conversion is needed (though the TMPU often has built-in options).

-

DIN-rail or Rack Mount Enclosures: For housing the TMPU unit.

-

Configuration Software: PC-based software provided by CCC for setting up channel parameters, alarms, and communication settings.

-

Signal Conditioners/Isolators (single-channel): The discrete components that the TMPU consolidates and replaces.

Reviews

There are no reviews yet.