GE Introduces DS200RT8AG3AHC: High-Resolution Terminal Board for Precision Turbine Control

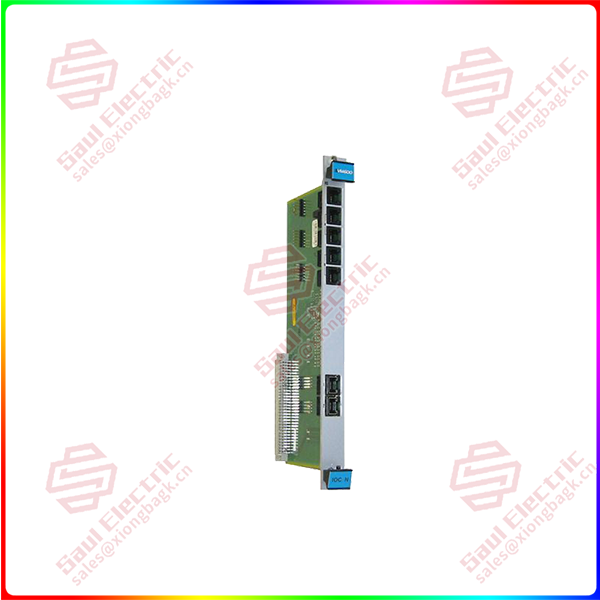

GE Power has announced the launch of the DS200RT8AG3AHC, a high-resolution terminal board designed for its Mark V and Mark VI series turbine control systems. This specialized module serves as a critical signal conditioning and interface unit, dedicated to processing high-precision analog feedback signals from critical sensors such as thermocouples, resistance temperature detectors (RTDs), and other low-level mV/mA transducers used for temperature and speed monitoring.

The DS200RT8AG3AHC is engineered to provide exceptional accuracy, stability, and noise immunity in the challenging electrical environment of a turbine control cabinet. It features advanced amplification, filtering, and isolation circuitry to convert delicate sensor signals into robust, high-fidelity digital data for the turbine’s primary controller (TMR). This precise data is fundamental for executing accurate control algorithms, ensuring safe operating temperatures, and enabling reliable protection functions.

«In turbine control, the accuracy of sensor data directly impacts efficiency, safety, and availability,» said a controls system engineer from GE’s Gas Power division. «The DS200RT8AG3AHC is engineered to be the trusted interface for our most critical measurements. Its high-resolution design and robust signal conditioning ensure the controller receives the clean, accurate data necessary to make optimal control decisions and protect the turbine from harmful conditions.»

Key Features and Benefits of the DS200RT8AG3AHC include:

-

High-Precision Signal Conditioning: Provides dedicated channels for high-accuracy temperature inputs (e.g., thermocouples Types J, K, T; RTDs) and other low-level analog signals, with built-in cold junction compensation and linearization for thermocouples.

-

Superior Noise Rejection and Isolation: Incorporates advanced filtering, shielding, and galvanic isolation techniques to protect sensitive measurement circuits from electromagnetic interference (EMI) and ground loops, which are prevalent near high-power equipment.

-

Triple Modular Redundancy (TMR) Compatibility: Designed for integration into TMR (Triple Modular Redundant) control systems, where three isolated channels process the same sensor signal for voting, ensuring the highest level of signal integrity and system availability.

-

Comprehensive Diagnostics: Includes onboard diagnostics to monitor channel health, detect open or shorted sensor conditions, and validate signal plausibility, providing early warning of sensor or wiring issues.

-

Direct System Integration: A plug-in component for the Mark V/VI I/O rack, fully configured and monitored through GE’s ToolboxST™ software. It ensures seamless data exchange with the turbine controller for real-time monitoring and historical trending.

The DS200RT8AG3AHC terminal board is available now for new turbine control system installations and as a critical service part for maintaining and upgrading the global fleet of GE gas and steam turbines. It is an essential component for ensuring the precision and reliability of the turbine’s core protection and control loops.