Description

Product Overview

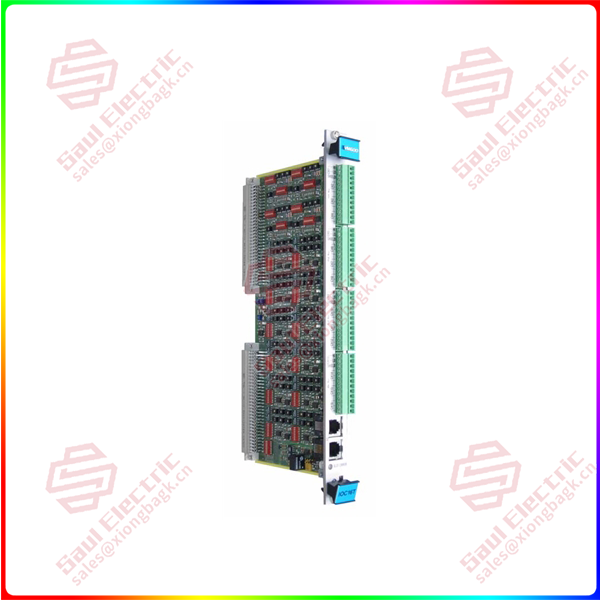

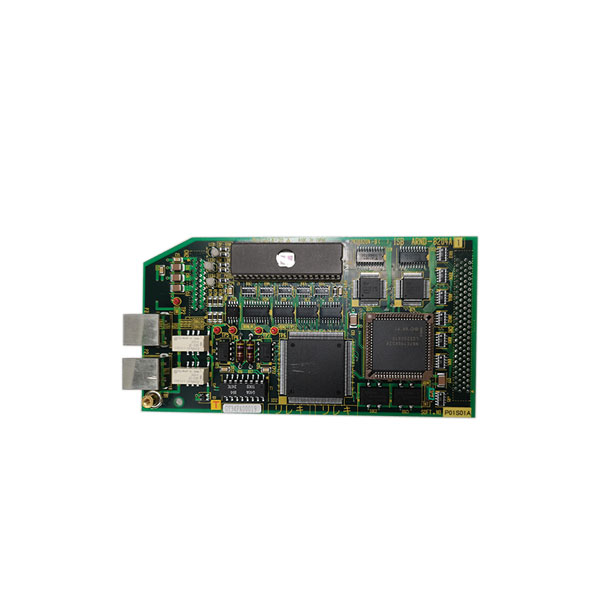

The VIBRO-METER VM600 IOC16T PNR200-565-000-013 is a high-density, specialized Input/Output Controller (IOC) module within the VIBRO-METER VM600 machinery condition monitoring and protection system, a product line of Baker Hughes Bently Nevada. This specific IOC16T variant is engineered as a dedicated, high-channel-count signal conditioning and interface unit, primarily for eddy current proximity transducers and other dynamic sensors. Its core function is to provide the excitation, signal conditioning, and acquisition for a large number of channels measuring radial vibration, axial position (thrust), eccentricity, and rotor speed (Keyphasor®) on critical rotating equipment such as turbines, compressors, and large pumps. The module supplies the regulated -24 V DC (or -18 V DC) power required by the proximity probes, conditions the returned high-frequency RF signal, and demodulates it to extract the dynamic vibration/displacement waveform and the static gap voltage (DC bias).

The extended part number

PNR200-565-000-013specifies its precise configuration, including the number of dedicated proximity probe input channels (likely 16, as suggested by «16T»), input voltage ranges, and any integrated output or communication options. The value of the VM600 IOC16T lies in its application-optimized design, reliability, and channel density. By consolidating a large number of critical vibration and position measurement channels into a single, robust module, it maximizes the monitoring capability within a limited rack space, simplifies system wiring, and ensures consistent, high-quality signal conditioning across all channels. For protection and reliability engineers in industries like power generation and oil & gas, this module is the essential hardware interface that transforms the raw analog signals from the most critical machinery sensors into clean, reliable data for continuous protection, performance monitoring, and advanced diagnostic analysis.Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

VIBRO-METER VM600 IOC16T PNR200-565-000-013

|

|

Manufacturer

|

VIBRO-METER (a Baker Hughes Bently Nevada company)

|

|

System Platform

|

VM600 Machinery Health Monitoring System

|

|

Product Type

|

High-Density Input/Output Controller for Proximity Transducers

|

|

Primary Function

|

Multi-channel signal conditioning and power supply for eddy current proximity probe systems.

|

|

Number of Channels

|

Likely 16 independent channels dedicated to proximity probe inputs (as indicated by «16T»).

|

|

Input Type/Sensor Compatibility

|

Specifically designed for Bently Nevada 3300 XL 8mm, 5mm, or 11mm Proximity Probes and associated extension cables. Accepts the modulated RF signal from the probe via a coaxial input.

|

|

Probe Excitation

|

Supplies regulated -24 V DC (typical) or -18 V DC power to each connected proximity probe.

|

|

Output Signals (per channel)

|

Provides two conditioned output signals:

|

-

Dynamic Output: AC-coupled signal proportional to vibration displacement (mils pk-pk or µm pk-pk).

VM600-IOC16T -

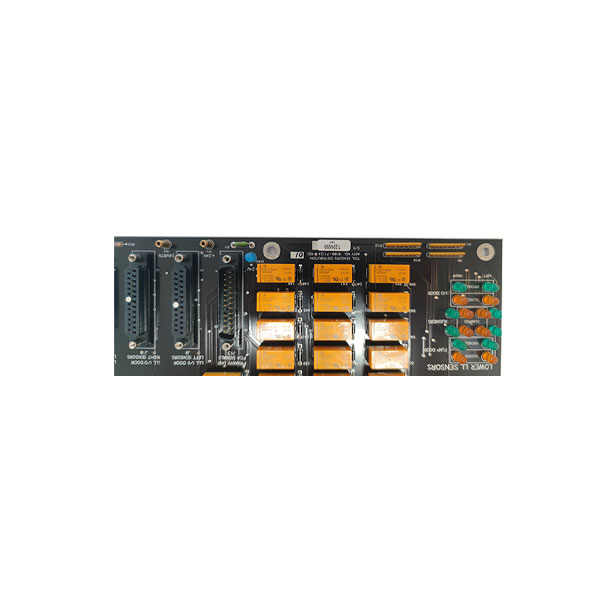

Gap Voltage (DC Bias): DC voltage proportional to the average gap between the probe tip and the observed surface (mils or µm DC).Signal Conditioning | Includes RF demodulation, filtering, and scaling. May have configurable bandwidth and integration/differentiation options.Diagnostics | Continuous monitoring per channel for sensor health: Open Probe Circuit, Shorted Probe Cables, and loss of signal.Connection | High-density coaxial connectors (e.g., BNC, TNC) or screw terminals for each channel, suitable for professional installation.Power Supply | Powered from the VM600 system backplane (e.g., ±15 V DC, +5 V DC).Communication/Integration | Interfaces with other VM600 modules (like MPC4 monitors) via the system’s internal bus to provide digitized or conditioned analog signals.Operating Temperature | 0°C to +70°C (for installation within a control enclosure).

Key Features and Advantages

VIBRO-METER VM600 IOC16T PNR200-565-000-013 excels through its application-specific optimization and high channel density. Its foremost advantage is providing a dedicated, high-performance platform for proximity-based measurements, which are the gold standard for monitoring radial vibration and position on high-speed rotating machinery. By housing 16 channels in one module, it offers an exceptional point density, which is crucial for comprehensive monitoring of multi-bearing machine trains (like a turbine-compressor-generator set) where dozens of vibration and position points need to be monitored simultaneously. This consolidation drastically reduces the number of modules, saving rack space, lowering power consumption, and simplifying the system architecture.

Superior signal integrity and built-in diagnostics are cornerstones of its design. The module provides clean, stable excitation voltage to the probes, which is critical for accurate and repeatable measurements. Its internal conditioning circuits are optimized to extract both the dynamic vibration component and the static gap voltage with high fidelity and low noise. The integrated sensor diagnostics are vital for system reliability; the ability to detect an open or shorted probe cable allows maintenance personnel to be alerted to a failing sensor beforeit provides bad data that could lead to a missed alarm or a false trip. This proactive health monitoring of the sensor loop itself is a key feature for safety-critical protection systems.

Seamless integration and reliability within the VM600 ecosystem are key benefits. The module is designed to plug directly into the VM600 rack and communicate seamlessly with monitoring processor cards. This ensures that vibration waveforms, gap voltages, and diagnostic status are readily available for protection logic, trending, and spectral analysis in systems like System 1™. Its robust industrial construction ensures long-term reliability in the demanding environments of power plants and compressor stations. For machinery engineers, the IOC16T delivers a dependable, high-density solution that forms the reliable sensory foundation for both machinery protection (alert/danger trips) and condition-based maintenance programs, maximizing asset availability and safety.

Application Areas

The VIBRO-METER VM600 IOC16T is deployed in condition monitoring systems for large, high-speed, critical rotating machinery where monitoring shaft vibration and position is paramount for safety and reliability.

Its primary application is in turbomachinery protection and monitoring:

-

Gas Turbines & Steam Turbines: Monitors radial vibration at each journal bearing, axial position (thrust bearing wear), and turbine eccentricity during startup/shutdown. A single IOC16T can often handle all proximity probes on a typical turbine.

-

Centrifugal & Axial Compressors: Provides essential vibration and position monitoring for anti-surge control and mechanical protection on critical pipeline, refinery, and process compressors.

-

Hydro Turbines & Generators: Monitors bearing vibration and shaft runout.

It is also used on large motors, pumps, and fans in critical service across industries like power generation (boiler feed pumps, ID/FD fans), oil & gas (mainline pumps), and petrochemicals. Essentially, the VM600 IOC16T is the interface of choice for any application requiring multiple channels of high-quality, proximity-based vibration and position measurement as part of a comprehensive machinery health management system.

Related Products

-

Bently Nevada 3300 XL 8mm Proximity Transducer System: The industry-standard proximity probes, extension cables, and proximitors that connect to the IOC16T.

-

VM600 Monitoring Processor Card (MPC4): The module that receives conditioned signals from the IOC16T to perform vibration analysis, alarm generation, and communication.

-

VM600 Rack, Backplane, and Power Supply: The hardware infrastructure that houses the IOC16T and other system components.

-

Bently Nevada System 1™ Software: The enterprise asset performance management platform that uses data from the VM600 system, fed by the IOC16T.

-

VM600 Configuration Software: Used to set up the IOC16T parameters, scale factors, and diagnostic thresholds for each channel.

-

BNC/TNC Coaxial Cables and Connectors: High-quality cables to connect field wiring to the IOC16T module’s inputs.

-

Velocity/Acceleration Input Modules (e.g., IOC4T for accelerometers): Other IOC modules used in conjunction with the IOC16T for a complete monitoring suite (casing vibration + shaft vibration).

-

Bently Nevada 3500/42 Proximitor Module: A legacy alternative for proximity probe conditioning in the 3500 system, whereas IOC16T is part of the newer VM600 platform.

Reviews

There are no reviews yet.