Description

Product Overview

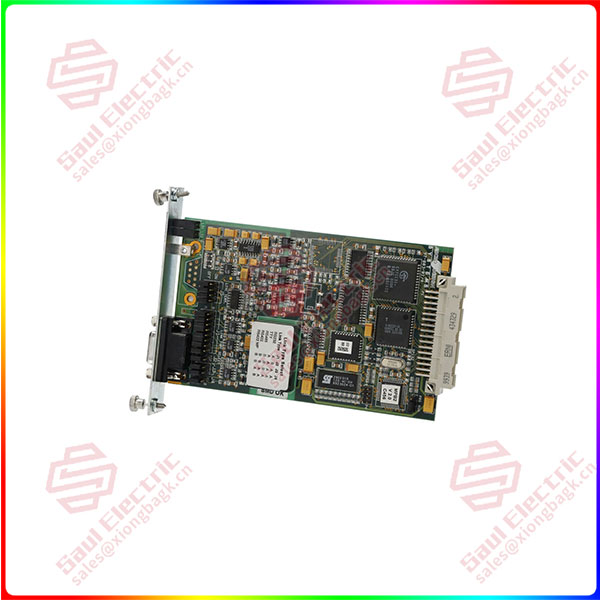

The MTL 8104-AO-IP is a highly specialized, high-performance Analog Output Isolator and I/P (Current-to-Pressure) Transducer Power Supply designed for use in hazardous areas, manufactured by MTL (Measurement Technology Ltd, part of Eaton). This integrated unit serves a critical function in process control systems, particularly for final control elements. Its primary role is to convert a standard 4-20 mA control signal from a safe-area source (e.g., a DCS or PLC controller) into a proportional, isolated output signal suitable for driving a pneumatic positioner or an I/P (Current-to-Pressure) transducer located in a hazardous area. The module provides the necessary power for the I/P transducer while simultaneously isolating the control signal, ensuring safe and reliable operation of control valves, dampers, or other pneumatically actuated devices in environments where flammable gases or dusts may be present.

The core value of the MTL 8104-AO-IP lies in its integration, safety, and reliability. It combines three essential functions into a single, certified device: 1) Signal Isolation to protect the control system from field-side transients and ground loops; 2) Power Supply for the connected I/P transducer; and 3) Hazardous Area Interface via appropriate protection concepts (likely Intrinsic Safety — Ex ia/ib or associated apparatus). The «AO-IP» designation clearly indicates its application for Analog Output driving I/P transducers. For control and instrumentation engineers in oil & gas, petrochemical, and pharmaceutical industries, the 8104-AO-IP simplifies the design and installation of control valve loops. It ensures that the precise control command from the system is accurately delivered to the valve actuator, regardless of the challenging electrical environment, while maintaining the strict safety barriers required for operation in classified hazardous zones.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

MTL 8104-AO-IP

|

|

Manufacturer

|

MTL (Eaton)

|

|

Product Type

|

Analog Output Isolator / I/P Transducer Power Supply (for Hazardous Areas)

|

|

Input Signal (Safe Area)

|

4-20 mA DC, typically sourced from a DCS/PLC analog output card.

|

|

Output to Hazardous Area

|

Provides a powered, isolated 4-20 mA output capable of driving the coil of an I/P transducer or a pneumatic positioner with a current input.

|

|

Output Power Capacity

|

Supplies sufficient voltage and current to power typical two-wire I/P transducers (e.g., 20-30 mA at a compliance voltage high enough to overcome line resistance and transducer voltage drop).

|

|

Isolation

|

Galvanic isolation between input and output circuits, and from the power supply. Typical isolation voltage is 1500 Vrms or higher.

|

|

Intrinsic Safety (if applicable)

|

Certified as an Associated Apparatus (for connection to intrinsically safe field devices) or may incorporate other protection methods suitable for the hazardous area. The output to the field is designed to be intrinsically safe (Ex ia/ib) when used with approved I/P transducers, allowing installation in Zone 0/1/2.

|

|

Accuracy

|

High accuracy, typically better than ±0.1% of span, ensuring precise control signal reproduction.

|

|

Linearity & Response Time

|

Excellent linearity and fast response time to accurately follow control signal changes.

|

|

Power Supply

|

Requires an external DC power supply (e.g., 24 V DC) for its own operation and to source the field output power.

|

|

Hazardous Area Certification

|

Certified for use in hazardous locations. Carries major international certifications: ATEX, IECEx, UKEX (e.g., [Ex ia] IIC or similar).

|

|

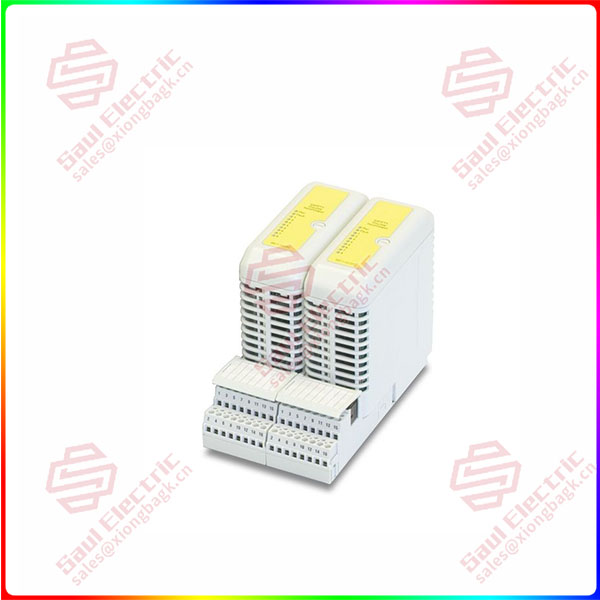

Mounting

|

Compact, DIN-rail mountable design for easy installation in marshalling or interface cabinets.

|

|

Operating Temperature

|

Standard industrial range, e.g., -20°C to +60°C.

|

|

Diagnostics/Indication

|

May include LED indicators for power and fault conditions.

|

Key Features and Advantages

MTL 8104-AO-IP excels through its purpose-built integration for control valve applications. Its primary advantage is combining signal conditioning, isolation, and I/P transducer power supply into one optimized, certified unit. This eliminates the need for separate components (isolator + separate IS power supply), reducing wiring complexity, saving panel space, and minimizing potential points of failure. The design is specifically tuned to match the electrical characteristics of common I/P transducers, ensuring reliable operation.

Superior signal integrity and intrinsic safety are fundamental to its design. The module provides high-grade isolation that protects the sensitive control system output card from ground loops, voltage spikes, and noise that can originate in field wiring or the hazardous area. If certified for intrinsic safety, its output circuits are designed to be energy-limited, preventing them from becoming an ignition source in the hazardous area, even under fault conditions. This allows the connected I/P transducer (which must also be certified as an intrinsically safe apparatus) to be installed in the most demanding zones (Zone 0/1).

Enhanced reliability and simplified compliance are key benefits. As a product from MTL, a leader in hazardous area technology, it is engineered for maximum reliability in critical control loops. Its use of proven isolation and power supply technology ensures long-term stability. The integrated, certified design dramatically simplifies the engineering and documentation process for safety loops, as a single device covers the interface requirements. For maintenance personnel, the compact, DIN-rail design allows for easy replacement if needed. In summary, the 8104-AO-IP provides a robust, safe, and efficient solution for one of the most common and critical interfaces in process automation—controlling final elements in hazardous areas—directly contributing to process safety, control loop performance, and overall plant availability.

Application Areas

The MTL 8104-AO-IP is specifically designed for interfacing control systems with pneumatically actuated final control elements in hazardous areas.

Its primary application is in control valve loops across various process industries:

-

Oil & Gas Production/Refining: Controlling fuel gas valves, pressure control valves, anti-surge valves, and emergency shutdown (ESD) valves on wellheads, pipelines, and process units.

-

Chemical and Petrochemical Plants: Managing reactor feed valves, distillation column control valves, and coolant valves.

-

Pharmaceutical and Fine Chemical: Precise control of batch reactor valves in solvent handling areas.

-

Power Generation: Governing fuel valves, steam bypass valves, and other critical control points in boiler and turbine systems located in classified areas.

Essentially, anywhere a DCS or PLC needs to safely and accurately control a pneumatically operated valve, damper, or other actuator via a 4-20 mA signal to an I/P transducer or positioner in a Zone 0, 1, or 2 hazardous location, the 8104-AO-IP is the ideal interface solution.

Related Products

-

Intrinsically Safe (Ex i) I/P Transducers or Pneumatic Positioners: The field devices in the hazardous area that are powered and controlled by the 8104-AO-IP (e.g., MTL or other certified IS I/Ps).

-

Control Valves/Pneumatic Actuators: The final control elements.

-

DCS/PLC Analog Output Cards: The source of the 4-20 mA control signal.

-

24V DC System Power Supply: Provides operating power to the 8104-AO-IP module.

-

MTL Intrinsic Safety Barriers (for other signal types): For digital or analog input loops.

-

DIN-rail Marshalling Cabinets: The typical location for installation of these interface modules.

Reviews

There are no reviews yet.