Description

Product Overview

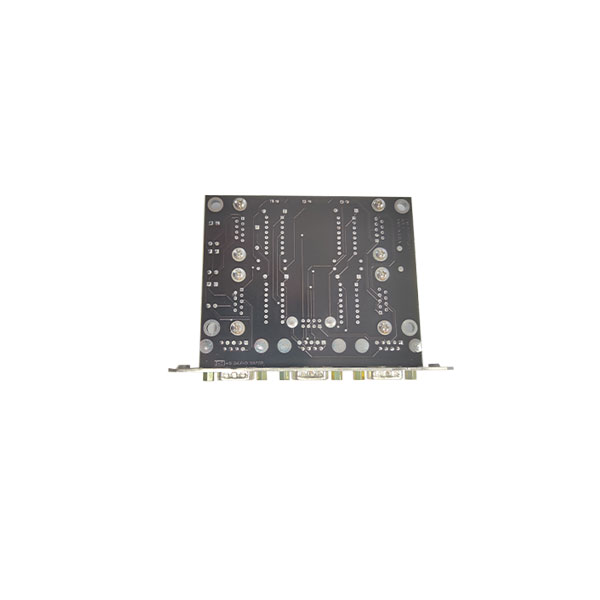

The MTL 8505-BI-MB is a highly specialized Digital Input Isolator and Modbus Gateway Module designed for interfacing with hazardous area equipment, manufactured by MTL (Measurement Technology Ltd, part of Eaton). This module serves a critical, dual-function role: it acts as a robust digital (discrete) input interface for acquiring the on/off status of field devices (like limit switches, solenoid valve position feedback, pushbuttons) located in hazardous areas, and it incorporates a Modbus communication interface for system integration. The designation «BI» indicates Binary Input, and «MB» denotes Modbus capability. Its primary function is to safely read the status of contacts or dry/wet switches in Zone 1/2 hazardous locations, provide galvanic isolation, and then make this status data available to a control or monitoring system via the widely used Modbus RTU industrial communication protocol.

The value of the MTL 8505-BI-MB lies in its combination of safety, connectivity, and intelligence. It bridges the gap between simple field contact signals and modern digital control networks. The module provides certified protection (often as an Associated Apparatus for Intrinsically Safe circuits) to prevent dangerous energy from reaching the hazardous area. It digitizes the status of multiple field contacts and packages this data into a Modbus register map, allowing a PLC, SCADA system, or asset management software to easily poll and retrieve the status of numerous field points over a single serial cable. For system integrators in oil & gas, chemical, and other process plants, the 8505-BI-MB dramatically simplifies the architecture for monitoring distributed discrete devices. It reduces wiring by multiplexing many signals onto a communication bus, provides enhanced diagnostic capabilities compared to simple relays, and offers a future-proof, network-ready interface for legacy field devices.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

MTL 8505-BI-MB

|

|

Manufacturer

|

MTL (Eaton)

|

|

Product Type

|

Digital Input Isolator with Modbus RTU Interface

|

|

Digital Input Channels

|

Typically provides multiple isolated digital input channels (e.g., 4, 8, or 16 channels) for monitoring dry contacts or wet contacts (with configurable voltage sensing).

|

|

Input Type

|

Configurable per channel or in groups for:

|

Key Features and Advantages

MTL 8505-BI-MB excels by integrating discrete I/O with industrial networking. Its primary advantage is multiplexing multiple discrete field signals onto a single Modbus RTU network. Instead of running individual wires for each field contact back to a central I/O rack, a single twisted-pair RS-485 cable can connect multiple 8505-BI-MB modules, each monitoring dozens of points, significantly reducing wiring, conduit, and installation costs, especially for large, distributed plants.

Enhanced safety and diagnostics are fundamental. The module provides certified intrinsic safety barriers on its input channels, ensuring safe operation in hazardous areas. Beyond simple switching, it offers configurable filtering (de-bounce), and the LED per channel provides immediate visual status, aiding in troubleshooting. Communication to a central system allows for remote monitoring of the health of the field contacts and the module itself, enabling predictive maintenance (e.g., detecting a chattering contact).

Configuration flexibility and system integration are key benefits. Inputs can be configured for different signal types, adapting to various field devices. Its standard Modbus RTU protocol ensures seamless integration with virtually any modern control or monitoring system without requiring proprietary drivers. The module acts as a smart gateway, converting raw contact closures into easily accessible data points in a SCADA database. For engineers, this represents a move towards a more intelligent, networked, and maintainable field device infrastructure, replacing traditional marshalling cabinets filled with simple isolators and reducing the I/O count on the main controller.

Application Areas

The MTL 8505-BI-MB is ideal for applications requiring remote monitoring of discrete device statuses in hazardous areas via a digital network.

Typical applications include:

-

Oil & Gas Platforms/Plants: Monitoring the status of emergency shutdown (ESD) pushbuttons, valve limit switches (open/close), pump running status, and fire & gas detection system outputs distributed across the facility.

-

Tank Farms: Monitoring high/low level switches, access door status, and pump controls.

-

Pipeline Valve Stations: Remotely monitoring the position of block valves and intruder detection switches.

-

Chemical Plants: Monitoring batch reactor permissives, agitator status, and safety interlock conditions.

Essentially, it is used wherever there is a need to gather the on/off status of many devices spread over a wide area in a hazardous location, and where bringing all those signals back to a central point via individual wires is impractical or costly. It enables the creation of a digital fieldbus for discrete signals.

Related Products

-

Intrinsically Safe (Ex i) Limit Switches, Pushbuttons: The field devices connected to the input channels.

-

MTL 8500 Series Power Supplies: 24V DC power supplies for the module network.

-

Modbus RTU Master Device: The PLC, RTU, or SCADA communication master that polls the 8505-BI-MB for data.

-

RS-485 Network Components: Cables, terminators, and repeaters for the Modbus network.

-

MTL 8500 Series Analog or Output Modules: Other modules in the same family for a complete I/O solution.

-

SCADA/HMI Software: The system that displays and logs the status data acquired by the module.

Reviews

There are no reviews yet.