Description

Product Overview

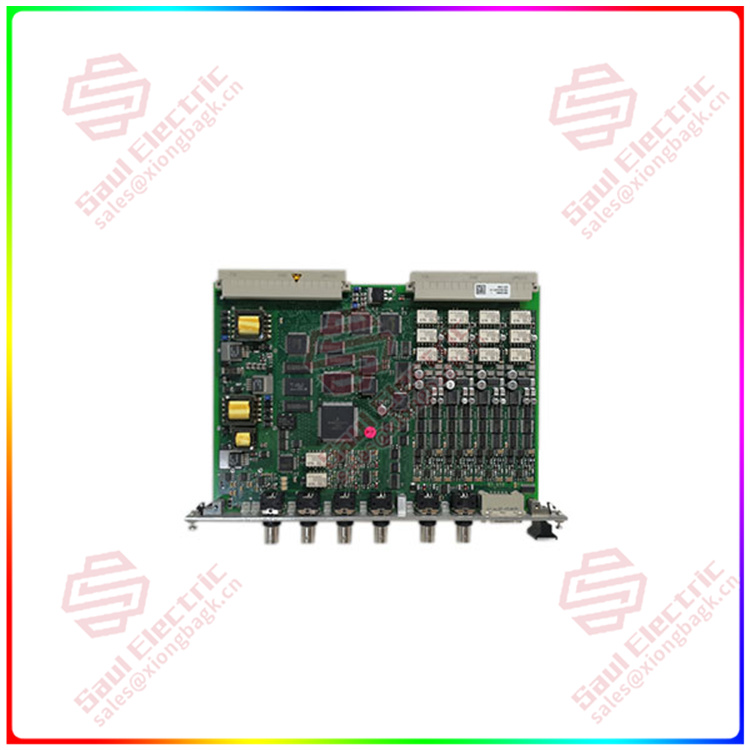

The VIBRO-METER VM600 MPC4 PNR200-510-070-113 is a core, high-performance Monitoring and Protection Controller module within the VIBRO-METER VM600 machinery condition monitoring and protection system, a flagship product of Baker Hughes Bently Nevada. This MPC4 module serves as the intelligent processing hub and decision-making engine for a segment of monitored channels within a VM600 rack. Its primary function is to acquire digitized sensor data from input conditioning modules (like the IOC series), execute sophisticated real-time signal processing and analysis, perform protection logic, generate alarms, and manage communication of results. It handles critical measurements from proximity probes, accelerometers, RTDs, and 4-20mA transducers, providing continuous protection (Alert and Danger trips) as well as detailed diagnostic information for condition-based maintenance.

The extended part number

PNR200-510-070-113specifies its exact configuration, including processing power, memory, and the number of monitoring channels it can support. The value of the VM600 MPC4 lies in its advanced diagnostic algorithms, robust protection functions, and seamless integration. It performs real-time Fast Fourier Transform (FFT) to convert time-domain vibration waveforms into frequency spectra, enabling the detection of specific fault patterns like unbalance, misalignment, and bearing defects. Equipped with dual redundant microprocessors, it ensures high reliability for protection functions. For maintenance and reliability engineers in industries like power generation, oil & gas, and heavy industry, the MPC4 is the «brain» that transforms raw sensor data into actionable intelligence—triggering immediate shutdowns to prevent catastrophic failures while providing the deep diagnostics needed to predict issues and plan maintenance, thereby maximizing asset availability and safety.Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

VIBRO-METER VM600 MPC4 PNR200-510-070-113

|

|

Manufacturer

|

VIBRO-METER (a Baker Hughes Bently Nevada company)

|

|

System Platform

|

VM600 Machinery Health Monitoring System

|

|

Product Type

|

Monitoring and Protection Controller Module

|

|

Processing Core

|

Dual redundant microprocessors for high reliability in protection functions.

|

|

Monitoring Channels

|

Capable of monitoring a defined number of dynamic (vibration/position) and static (temperature/process) channels. The exact count is defined by the order code (e.g., may support 16 or 32 dynamic channels).

|

|

Signal Processing

|

Real-time FFT Analysis: Generates vibration spectra for each dynamic channel.

|

-

Overall Level Calculation: Computes overall vibration amplitude (peak, RMS, etc.).

-

Harmonic & Band Alarm Monitoring: User-definable frequency bands for tracking specific machine components (e.g., 1X, 2X, blade pass frequency).Protection Functions | Dual-Level Alarm Logic: Configurable Alert and Danger (Trip) setpoints with time delays.

VM600 MPC4 200-510-100-034 -

Sensor & System Diagnostics: Monitors for probe faults, system faults, and invalid data.

-

Programmable Logic: Allows for custom trip equations and permissives.Data Storage | Onboard memory for storing waveform snapshots, spectra, and event data associated with alarms and trips.Communication | High-speed link to VM600 communication modules (CMC) for data export to plant networks and software like System 1™. Communicates with I/O modules (IOC) via rack backplane.Display & Interface | Status LEDs. Full configuration and data viewing is performed via connected software.Power Supply | Powered from the VM600 rack backplane.Operating Temperature | 0°C to +60°C (for controlled environments).Certifications | Designed for critical protection applications, complying with relevant machinery protection standards.

Key Features and Advantages

VIBRO-METER VM600 MPC4 PNR200-510-070-113 is distinguished by its powerful integration of protection and diagnostics. Its core advantage is performing real-time spectral analysis on every monitored vibration channel. This allows it to not only react to an overall level exceeding a threshold but also to identify the mechanical causeof the change (e.g., rising 1X amplitude indicating unbalance). This diagnostic capability, embedded within the protection controller itself, provides immediate insight during an alarm event. The dual-redundant processor architecture ensures the integrity of the protection logic, making it suitable for safeguarding the most critical assets.

Flexible and intelligent alarming is a cornerstone of its design. Beyond simple level-based alarms, the MPC4 supports band alarms that monitor vibration energy in specific frequency ranges. This enables early detection of issues like gear mesh problems, bearing defects, or aerodynamic instability. Its programmable logic allows engineers to create complex trip equations, incorporating permissives, voting (2-out-of-3), and latching logic, tailoring the protection scheme precisely to the machine’s needs. The module’s ability to capture and store high-resolution waveform and spectrum snapshots pre- and post-trip is invaluable for forensic analysis, dramatically reducing root-cause investigation time.

Seamless system integration and scalability are key benefits. The MPC4 is designed to work in concert with other VM600 modules (IOC for I/O, CMC for comms) within a scalable rack system. Multiple MPC4 modules can be installed in a single rack to monitor hundreds of points on a large machine train. Data flows seamlessly from the MPC4 to enterprise systems via the CMC communication module. For asset managers, the MPC4 delivers a future-proof solution that provides not only reliable safety protection but also the rich diagnostic data foundation needed for predictive maintenance programs, advanced analytics, and overall operational excellence.

Application Areas

The VIBRO-METER VM600 MPC4 is the central processing unit for protection and monitoring systems deployed on large, critical, high-speed rotating equipment.

Its primary application is in turbomachinery protection and diagnostics:

-

Gas Turbines & Steam Turbines: Monitors bearing vibration, shaft position, and casing vibration for protection, while providing spectra for diagnosing imbalance, misalignment, oil whirl, and rotor rubs.

-

Centrifugal & Axial Compressors: Essential for anti-surge control support and mechanical protection, detecting conditions like subsynchronous vibration indicative of instability.

-

Large Pumps & Fans: Provides protection and diagnostics for critical boiler feed pumps, induced/forced draft fans, and main coolant pumps.

It is also extensively used on electric motors, generators, gearboxes, and rolling mills in heavy industry. Essentially, the VM600 MPC4 is applied wherever there is a need for continuous, online protection combined with advanced diagnostic capabilities for rotating or reciprocating machinery, typically where unplanned failure carries significant safety or financial risk.

Related Products

-

VM600 Input/Output Controller Modules (IOC, e.g., IOC4T, IOC16T): Provide conditioned sensor signals to the MPC4.

-

VM600 Communication Module (CMC, e.g., CMC16): Transmits data from the MPC4 to plant networks and software.

-

VM600 Rack, Backplane & Power Supply (RPS): The hardware infrastructure housing the MPC4 and other modules.

-

Bently Nevada 3300 XL & 3500 Proximity Transducer Systems: The primary sensors whose signals are processed by the MPC4.

-

Bently Nevada System 1™ or APM Software: The enterprise platform that archives and analyzes historical data from the MPC4.

-

VM600 Configuration Software (Workbench): Used to configure all parameters, alarms, spectra, and logic for the MPC4 module.

-

Portable Data Collectors/Analyzers: Can often connect to or complement the online system managed by the MPC4.

Reviews

There are no reviews yet.