Description

Product Overview

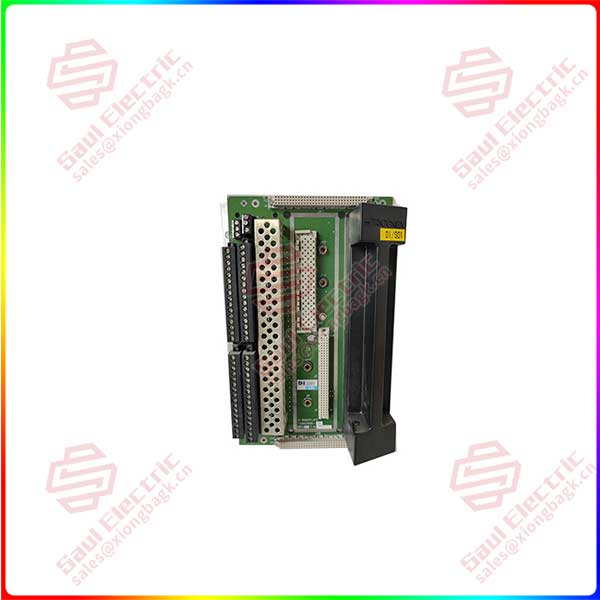

The TRICONEX AI2361 7400210-020 is a high-precision, high-integrity Analog Input Module, a critical component within the Triconex (a Schneider Electric company) family of triple modular redundant (TMR) safety instrumented systems (SIS) and critical control systems. This specific model, with the detailed part number 7400210-020, is engineered to provide reliable acquisition and conditioning of analog process signals from field transmitters and sensors as part of safety instrumented functions (SIFs). Its primary function is to interface with 4-20 mA current loop transmitters, thermocouples, RTDs, or other analog sources, converting these signals into high-resolution digital values. Operating within the TMR architecture, the AI2361 incorporates three independent input and conversion channels per analog point that work in parallel. The system employs a sophisticated voting or mid-value selection algorithm on the digitized results, producing a single, highly reliable process value for use by the Tricon safety controller, even if one of the three internal signal paths fails.

The core value of the TRICONEX AI2361 7400210-020 lies in its fault tolerance, precision, and comprehensive diagnostic coverage for SIL-rated analog measurement applications. Designed to meet Safety Integrity Level (SIL) 2/3 requirements per IEC 61508/61511, it provides robust galvanic isolation to protect the control system from field-side hazards. Each channel includes continuous self-diagnostics to monitor for sensor burnout (open circuit for TCs/RTDs), signal out-of-range, short circuits, loss of loop power, and internal hardware faults. For engineers in industries such as oil & gas, petrochemicals, and power generation, deploying the AI2361 ensures that critical process variables like pressure, temperature, level, and flow are measured with the integrity required for safety-related trips and permissives, forming a reliable sensory foundation for systems like emergency shutdown (ESD), fire and gas (F&G), and turbine overspeed protection.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

TRICONEX AI2361 7400210-020

|

|

Manufacturer

|

Triconex (Schneider Electric)

|

|

System Platform

|

Tricon TMR (Triple Modular Redundant) Safety & Critical Control System

|

|

Product Type

|

High-Integrity Analog Input Module

|

|

Number of Channels

|

Typically 8 or 16 isolated analog input channels (specific to AI2361 variant).

|

|

Input Signal Types

|

Configurable per channel: 4-20 mA, 0-20 mA, 0-5V, 0-10V, ±10V, thermocouple (J, K, T, etc.), RTD (Pt100, Cu10, etc.), mV.

|

|

Resolution

|

High resolution, typically 16-bit analog-to-digital conversion per channel.

|

|

Accuracy

|

High accuracy, typically better than ±0.1% of reading for standard current/voltage inputs.

|

|

Isolation

|

High-grade isolation between field channels and between field side and system logic. Isolation voltage typically 1500 Vrms or higher.

|

|

Voting Architecture

|

Employs TMR (2-out-of-3) voting on the digitized value from three independent signal paths per channel. Outputs a single, voted high-integrity value to the Main Processor.

|

|

Update Rate

|

Deterministic scan rate synchronized with the TMR controller.

|

|

Diagnostics

|

Comprehensive per-channel diagnostics: Sensor Burnout Detection (for TC/RTD), Open Circuit, Short Circuit, Signal Over-range/Under-range, Loss of Loop Power, and Module Internal Fault (A/D converter, memory).

|

|

Transmitter Power

|

Can provide loop power for 2-wire 4-20 mA transmitters (sourcing) on configured channels.

|

|

Status Indication

|

Front-panel LEDs for module health and often per-channel or per-group status.

|

|

Hot Swap

|

Supports online insertion and removal (hot swap) in compatible Tricon chassis when following approved procedures.

|

|

Power Supply

|

Powered from the Tricon chassis backplane.

|

|

Certifications

|

Designed and certified for use in SIL 2/3 safety applications per IEC 61508/61511. FM, CSA, ATEX/IECEx for hazardous locations.

|

Key Features and Advantages

TRICONEX AI2361 7400210-020 excels through its inherent fault tolerance and safety-focused design for analog measurements. The triple-redundant architecture per analog channel is its fundamental advantage, providing an extremely high level of availability and safety. The system can tolerate a failure in one of the three parallel signal paths (including a complete failure of one A/D converter) without any loss of accuracy or generation of a false reading, as the voted output remains valid based on the two healthy paths. This makes it ideal for applications where a single measurement error could lead to a hazardous event or a costly unnecessary shutdown.

Superior signal integrity and diagnostic intelligence are critical for reliable safety system operation. The module provides high-quality signal conditioning with filtering to reject noise, ensuring accurate measurement even in electrically harsh environments. Its comprehensive suite of diagnostics goes beyond simple value checking; it actively monitors the health of the sensor loop (detecting open thermocouples, broken RTD wires) and the integrity of the internal measurement circuitry. These diagnostics are communicated to the Tricon controller, enabling predictive maintenance and ensuring the safety loop’s integrity is continuously verified—a key requirement for achieving and maintaining high Safety Integrity Levels (SIL).

Flexibility and high availability are engineered into its operation. The ability to configure each channel for different signal types (mA, V, TC, RTD) via software provides tremendous application flexibility, reducing the variety of spare modules needed. The module is hot-swappable, allowing for replacement without requiring a system shutdown, which maximizes the operational availability of the entire safety instrumented system. Clear per-channel LED indicators provide instant visual fault location, speeding up troubleshooting. For safety system engineers, the AI2361 delivers not only precise and reliable analog measurement but also the diagnostic evidence and architectural robustness needed to design and maintain SIL-rated safety loops with confidence.

Application Areas

The TRICONEX AI2361 7400210-020 analog input module is deployed in the most critical measurement points within Safety Instrumented Systems (SIS) and critical control systems across high-hazard process industries.

In oil & gas facilities, it is used to measure critical variables for Emergency Shutdown (ESD) systems: separator pressures and levels, compressor discharge temperatures and pressures, and wellhead parameters. Within petrochemical and refinery process units, it interfaces with sensors monitoring reactor temperatures and pressures, distillation column levels, and furnace tube temperatures where deviations require immediate safety action.

For turbomachinery control (gas/steam turbines), it provides high-integrity measurements of speed, vibration, bearing temperatures, and exhaust temperatures for protection systems. In power generation burner management and boiler control, it measures fuel flow, drum level, and steam temperature for permissive and trip logic. It is also applied in fire and gas (F&G) systems for analog signals from toxic or combustible gas detectors. Essentially, the AI2361 is used wherever an analog process variable is part of a safety instrumented function (SIF) with a SIL 2 or SIL 3 requirement, and where measurement reliability is paramount for the protection of people, the environment, and assets.

Related Products

-

TRICONEX Main Processor (MP): The TMR controller that executes logic based on voted analog inputs from the AI2361.

-

TRICONEX Digital I/O Modules (e.g., DI3361, DOxxx): For interfacing with discrete field devices in the same safety system.

-

TRICONEX Analog Output Modules (e.g., AO3482): For executing analog safety actions.

-

Tricon Chassis and Power Supply: The hardware platform that houses and powers the TMR modules.

-

Tricon Communication Modules: For integrating the TMR system with a DCS or other plant networks.

-

TriStation 1131 Software: The configuration and programming environment for the entire Tricon system, including analog module configuration.

-

Field Sensors and Transmitters: The safety-instrumented (SIL-rated) pressure, temperature, and flow transmitters that provide signals to the AI2361.

-

IS (Intrinsic Safety) Barriers or Isolators: Often used in hazardous areas between the field device and the AI2361 module.

Reviews

There are no reviews yet.