Description

Product Overview

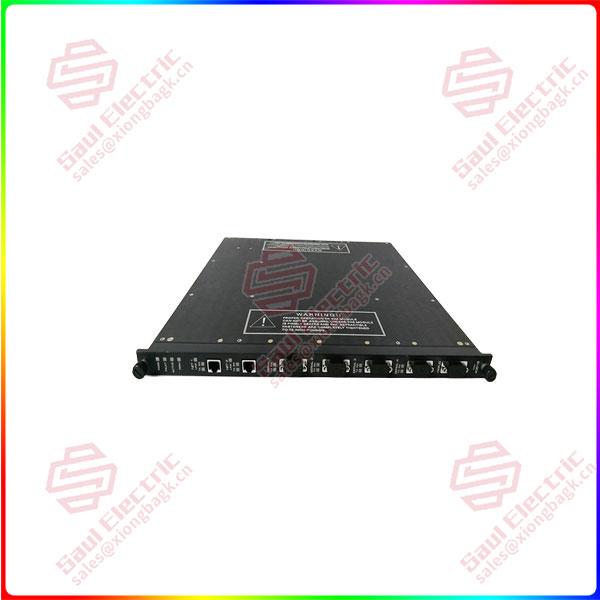

The Emerson EICM 4119A is a Controller Area Network (CAN) Interface Module for the DeltaV S-series Electronic Marshalling system. It is a critical component that provides a high-speed, robust, and deterministic CAN bus communication pathway between the DeltaV CHARMs I/O conditioning modules and the DeltaV controller. Specifically, it serves as the CANbus network interface for the DeltaV SIS (Safety Instrumented System) with Electronic Marshalling, connecting the I/O termination hardware to the safety logic solver. The EICM 4119A acts as the bridge, transporting I/O data from the field-terminated CHARM I/O cards to the redundant pair of DeltaV S-series controllers (for standard control) or the Triconex SIS controller, enabling the Electronic Marshalling architecture’s flexibility and reduced wiring.

The core value of the EICM 4119A lies in its role as the communication backbone for Emerson’s innovative Electronic Marshalling system, specifically for safety applications. It eliminates the traditional hardwired association between a specific I/O point and a specific controller channel. Instead, the 4119A allows any CHARM I/O point to be electronically «marshaled» (assigned) to any function in the controller via software configuration. In SIS applications, this provides immense flexibility for testing, maintenance, and system modifications without physically rewiring safety loops. For engineers and operators managing integrated control and safety systems (ICSS) in oil & gas, petrochemical, and other process industries, the EICM 4119A is the critical data highway that ensures reliable, deterministic, and redundant communication of safety-critical I/O data between the field and the SIL 3 certified Triconex logic solver, forming the foundation of a modern, flexible safety system.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

Emerson EICM 4119A

|

|

Manufacturer

|

Emerson Automation Solutions (part of the DeltaV / Triconex S-series with Electronic Marshalling product line)

|

|

Product Family

|

DeltaV Electronic Marshalling I/O Carriers

|

|

Primary Function

|

CANbus Interface Module for DeltaV SIS (Electronic Marsharding)

|

Communication & Networking

-

Communication Protocol: CAN (Controller Area Network) bus, based on the CANopen application layer protocol.

-

Data Transport: Transfers I/O data (both standard and safety) between the CHARM I/O modules on the DeltaV CHARM I/O Card (CIOC) and the controllers.

-

Network Topology: Connects in a redundant, fault-tolerant bus topology. Typically, two EICM 4119A modules are used (one per CAN network segment) to provide communication redundancy.

-

Connections: Interfaces with the CIOC backplane on one side and provides a CANbus connector on the front for network cabling.

-

Determinism: Provides deterministic, high-speed I/O scan times suitable for both process control and safety instrumented functions.Hardware & Integration

-

Form Factor: A plug-in circuit card module that installs into a dedicated slot on the DeltaV S-series CHARM I/O Card (CIOC) Carrier.

-

Compatibility: Designed for use with the DeltaV S-series I/O subsystem for both standard process control (connected to DeltaV controllers) and Triconex SIS (connected to Triconex S-series controllers like the SIS 1502).

-

Power Supply: Receives power from the CIOC Carrier backplane.

-

LED Indicators: Front-panel status LEDs indicating Power, Network Status, Module Health, and Communication Activity for rapid visual diagnostics.

-

Mounting: Installs in the designated communication slot of the CIOC Carrier tray.Performance & Environmental

-

Data Throughput: Supports the high-speed data transfer required for the I/O count and update rates of the associated CIOC carrier.

-

Redundancy: Supports a redundant communication network configuration. If one CAN network fails, the other maintains communication.

-

Operating Temperature: Typically 0 to 60°C (32 to 140°F) for standard industrial environments.

-

Certifications: Complies with relevant standards for use in SIL 3 (IEC 61508/61511) certified safety systems when used as part of a complete DeltaV SIS with Triconex solution.

Key Features and Advantages

Enables Electronic Marshalling Architecture: The primary function of the EICM 4119A is to facilitate the Electronic Marshalling concept. It breaks the physical link between I/O hardware and controller strategy, allowing I/O assignment to be done entirely in software. This dramatically reduces engineering time, wiring costs, and facilitates future modifications.

Redundant and Deterministic Communication: The module supports a redundant CAN bus network, ensuring high availability of the critical I/O data path. Its deterministic performance guarantees that safety I/O data is scanned and updated within a known, reliable timeframe, which is essential for SIL-rated safety loops.

Seamless Integration of Control and Safety: The EICM 4119A is a key component that allows both standard DeltaV control I/O and Triconex safety I/O to reside on the same CHARM I/O Card (CIOC) hardware platform. It provides the dedicated, high-integrity data path for safety I/O to the SIS controller, while standard I/O uses a separate path to the process controller, all within the same physical marshalling structure.

Simplified Maintenance and Reduced Spares: Since the EICM 4119A and the CHARM I/O modules are standard across many applications, inventory of spare parts is simplified. The module’s hot-swappable nature (when designed into a redundant pair) allows for replacement without system downtime.

Application Areas

The EICM 4119A is specifically designed for use in modern process automation projects utilizing Emerson’s DeltaV S-series with Electronic Marshalling, particularly those with integrated safety (DeltaV SIS).

-

DeltaV SIS (Safety Instrumented Systems): Used in safety systems where Triconex S-series controllers (e.g., SIS 1502) are integrated with DeltaV. The 4119A provides the CANbus link from the CHARM I/O to the safety controller for critical Emergency Shutdown (ESD), Fire & Gas (F&G), and Burner Management (BMS) I/O points.

-

Large-Scale Greenfield or Brownfield Projects: Where the flexibility of Electronic Marshalling is chosen to de-risk late design changes, reduce wiring, and speed commissioning.

-

Integrated Control and Safety Systems (ICSS): In facilities where a single, unified I/O infrastructure (Electronic Marshalling) serves both the basic process control system (BPCS) and the safety instrumented system (SIS), the EICM 4119A is the dedicated communication path for the safety portion.

-

Oil & Gas, Petrochemical, Pharmaceutical: Any industry employing Emerson’s DeltaV system with integrated Triconex SIS and seeking the benefits of the CHARM I/O and Electronic Marshalling architecture.

Related Products

-

DeltaV CHARM I/O Card (CIOC) Carrier: The base hardware tray (e.g., CIOC-4, CIOC-8) that houses the CHARM I/O modules, power supplies, and the EICM communication modules.

-

DeltaV / Triconex CHARM (Choice for Highly Advanced Remote Marshalling) I/O Modules: The actual I/O conditioning modules (e.g., Analog Input CHARM, Digital Output CHARM) that plug into the CIOC Carrier. The EICM 4119A communicates with these.

-

Triconex S-series SIS Controller: The safety logic solver (e.g., SIS 1502) that receives safety I/O data from the EICM 4119A over the CANbus network.

-

DeltaV S-series Controller: The process controller (e.g., S-series controller) for standard control I/O (which may use a different EICM module, like the 4106 for Ethernet/IP).

-

Power Supply: The DeltaV PS-4 or similar power supply modules for the CIOC Carrier.

-

DeltaV / Triconex S-series System Software: The engineering and configuration software (DeltaV/DeltaV SIS engineering tools) used to configure the I/O assignment, network, and controller logic.

-

CANbus Network Cables: Redundant, shielded cables to connect the EICM 4119A modules to the controllers.

Reviews

There are no reviews yet.