Description

WOODWARD 5441-693 — Digital Actuator Control Module

Product: 5441-693, Digital Servo Drive / Actuator Control Module

Manufacturer: Woodward, Inc.

Primary Application: A digital servo controller/amplifier designed to drive and control electro-hydraulic actuators (EHAs) or electro-mechanical actuators used for precise positioning of fuel valves, inlet guide vanes, or other final control elements in gas turbines, steam turbines, and large diesel engines.

1. Core Overview & Positioning

The Woodward 5441-693 is a member of the 5441 series of digital servo drives, representing a specific hardware/software configuration within that line. It functions as the high-performance interface between a digital governor’s low-level control signal and the high-power requirements of a servo actuator. Its role is critical in translating a position command into exact, dynamic physical movement.

Key Concept: It closes a high-speed, inner control loop using position feedback, ensuring the actuator follows the governor’s commands with precision, stability, and rapid response—essential for effective speed, load, and process control.

2. Key Features & Functions

-

Closed-Loop Position Control: Continuously compares the position command from the primary controller (e.g., 723PLUS) with the actual position feedback from an LVDT/RVDT sensor and adjusts its output to eliminate any error.

-

Flexible I/O: Typically accepts a variety of command signals (e.g., ±10V DC, 4-20mA, digital) and provides a high-current output suitable for driving inductive servo valve coils.

-

Advanced Integrated Control: Contains sophisticated control algorithms (PID with advanced compensation) optimized for demanding actuator dynamics.

-

Comprehensive Diagnostics & Protection:

-

LVDT/RVDT Monitoring: Detects sensor faults (open circuit, short circuit, loss of excitation).

-

Actuator/Driver Fault Detection: Monitors for coil faults, over-current, excessive position deviation, and communication loss.

-

Fail-Safe Behavior: Can be configured to drive the actuator to a predefined safe position upon a fault.

-

-

Field Configurability & Tuning: All operating parameters—input/output scaling, servo loop gains (P, I, D, feedforward), current limits, and fault settings—are configured and tuned via software (Woodward Toolkit) to match the specific actuator and application.

-

Communication: Equipped with communication ports (often a proprietary Woodward bus like Gov. Bus or NetBus) for integration with the primary controller, configuration, and real-time diagnostics.

3. Common Technical Specifications

-

Part Number Context: The

-693suffix defines the specific variant, indicating its firmware version, connector types, and possibly its default calibration or application focus. -

Command Input: Configurable for analog (±10V DC, 4-20mA) or digital (synchronous serial) input.

-

Feedback Input: Designed for AC LVDT/RVDT sensors (standard excitation: e.g., 3 Vrms @ 2.5 kHz or 5 Vrms @ 5 kHz).

-

Output Drive: Current output stage capable of driving typical servo valve coils (e.g., 0 to ±200 mA range).

-

Power Supply: Requires external DC power supplies, typically ±15V DC for control electronics and a separate +24V to +80V DC for the high-side output stage.

-

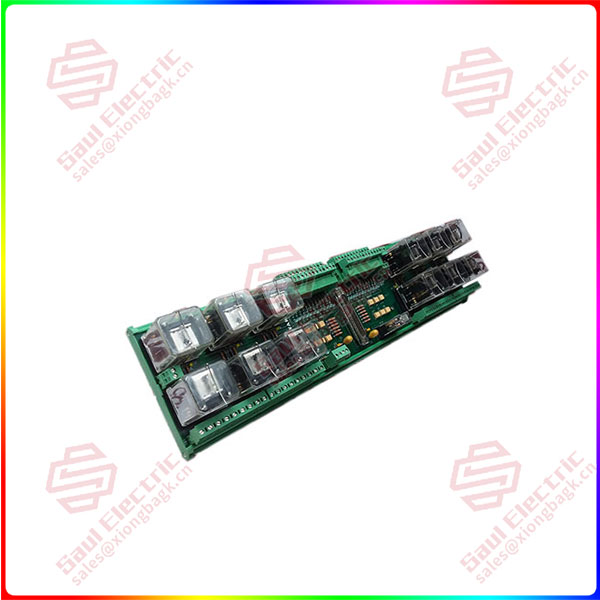

Physical Form: A printed circuit board assembly designed for mounting in a dedicated chassis or control cabinet, often with robust connectors for power, signals, and communication.

4. System Integration & Configuration

-

System Role: It is the «muscle» in the control loop, directly interfacing with the actuator. The primary governor (e.g., 723) is the «brain» calculating the setpoint.

-

Configuration Software: Exclusively configured using Woodward Toolkit software. The setup process includes:

-

Defining input/output signal types and scaling.

-

Performing an LVDT calibration to map the sensor’s electrical output to the actuator’s physical stroke.

-

Servo Tuning: Adjusting PID gains and other dynamic compensation to achieve fast, stable, and oscillation-free response.

-

-

Critical Calibration: Mechanical calibration (linking the LVDT core to the actuator rod) is a precise, mandatory step for accurate control.

5. Typical Applications

This module is used in high-performance applications requiring precise and reliable actuation:

-

Aeroderivative & Heavy-Duty Gas Turbines: Controlling fuel metering valves for acceleration, deceleration, and load control.

-

Steam Turbines: Positioning governor valves and intercept valves.

-

Diesel & Dual-Fuel Engines: Governing fuel injection actuators for speed and load regulation.

-

Compressor Control: Driving anti-surge valves and performance control valves.

Reviews

There are no reviews yet.