Description

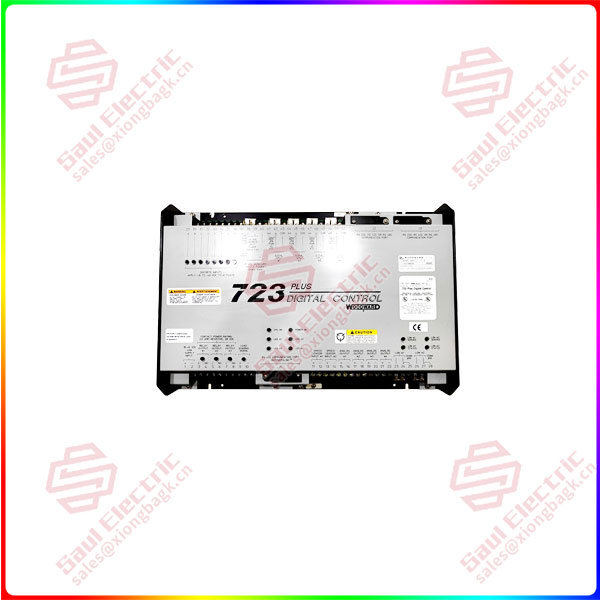

WOODWARD 9907-135 — Technical Overview

Product: 9907-135, I/O Expansion Board / Module

Manufacturer: Woodward, Inc.

Primary Application: An Input/Output (I/O) expansion module designed to add configurable discrete I/O points to Woodward 505/505XT Digital Speed Control Systems for steam turbines and other prime movers.

1. Core Overview & Positioning

The Woodward 9907-135 is a specialized hardware module that extends the I/O capacity of the standard 505/505XT control unit. The base 505/505XT has a fixed number of built-in I/O points; this expansion board provides additional, software-configurable channels for interfacing with more field devices, enabling more complex control schemes without needing a separate PLC.

Key Philosophy: It offers flexibility by allowing each of its channels to be individually defined as an input or output, adapting the governor’s interface capabilities to the specific needs of the turbine installation and its auxiliary systems.

2. Key Features & Functions

-

Expanded I/O Capacity: Adds a bank of configurable I/O points to the base 505/505XT controller.

-

Configurable I/O Points: Each channel is software-configurable via Woodward’s configuration software (Toolkit) as either a discrete input (DI) or a discrete output (DO). This provides significant design and application flexibility.

-

Isolated Circuits: Channels are designed with electrical isolation to protect the sensitive control electronics from noise, voltage transients, and ground loops present in industrial field wiring.

-

Seamless Integration: Once installed and configured, the added I/O points become fully integrated into the 505’s control logic. They can be used in the unit’s ladder logic programming or linked to control parameters.

-

Direct Mounting: Plugs directly into a dedicated connector on the main processor board of the 505/505XT unit, housed within the same chassis.

3. Common Technical Specifications

-

Compatibility: Designed specifically for the Woodward 505 and 505XT Digital Speed Control Units. It is not a standalone controller.

-

Module Type: Digital I/O Expansion Board.

-

I/O Count: Typically provides 8 configurable discrete I/O points (though the exact count should be verified against the specific manual for the -135 variant).

-

I/O Type: Discrete (Digital) only. Each point is a single on/off channel.

-

Voltage Ratings: The specific voltage level (e.g., 24 V DC, 120 V AC) is determined by the user-supplied external power source connected to the module’s terminal strip. The board provides the isolated switching path.

-

Connection: Field wiring is connected via a removable screw terminal block on the module’s faceplate.

-

Configuration: All points are configured (as DI or DO, with tag names and logic) using Woodward 505/505XT Toolkit software.

4. System Integration & Configuration

-

Role: Serves as a slave I/O extension to the master 505/505XT controller. All logic and decision-making reside in the main 505 processor.

-

Configuration Software: The module’s I/O points are defined within the 505’s control program using Woodward Toolkit. The engineer assigns each point a function, a tag name, and links it to the control logic.

-

Typical Signal Connections:

-

As an Input (DI): Can be connected to field contacts (e.g., pressure switch, limit switch, remote start signal) to provide status or permissive signals to the governor.

-

As an Output (DO): Can be connected to relay coils, solenoid valves, or indicator lamps to control auxiliary equipment or provide status indications from the governor.

-

5. Typical Applications

This module is used when the standard I/O on a 505/505XT is insufficient for the plant’s control strategy:

-

Adding Auxiliary Permissives/Interlocks: Connecting additional lube oil pressure switches, vibration switches, or valve position limits.

-

Enhanced Control Sequences: Providing outputs to control additional solenoid valves, clutch actuators, or auxiliary pumps as part of the turbine start/stop sequence.

-

Improved Plant Communication: Adding more status points (e.g., «Governor in Auto,» «Turbine Ready») to send to a Plant DCS/SCADA, or receiving more control commands.

-

Local Annunciation: Driving additional alarm or status lights on the local control panel.

Reviews

There are no reviews yet.