Description

Product Overview

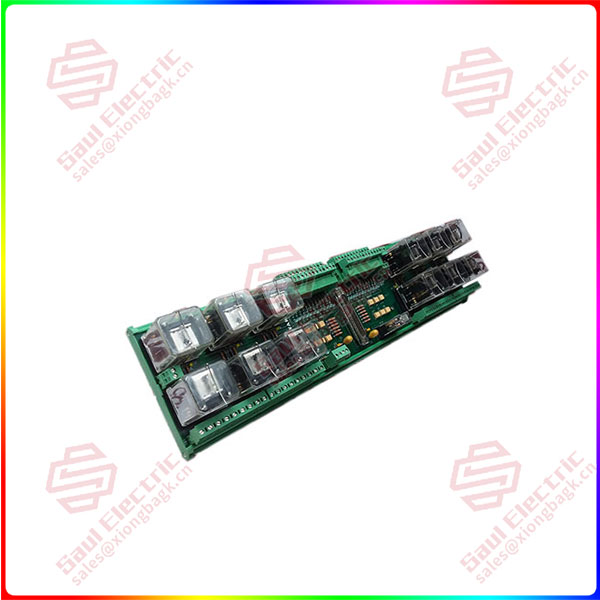

The WOODWARD 5501-465 is a critical electronic control module, specifically a Fuel Control or Actuator Driver Module, integral to Woodward’s precision fuel management systems for gas and diesel engines, as well as gas turbines. This module serves as the intelligent interface between the engine’s primary control unit (such as a Woodward 2301A speed controller or a modern digital governor) and the final fuel metering device—typically a hydraulic actuator, electronic fuel injector, or fuel valve. Its primary function is to convert a low-power control signal (often a current or voltage command representing the desired fuel flow) into a high-power, precisely modulated output signal capable of driving the fuel actuator with the force, speed, and accuracy required for stable engine operation. The 5501-465 is responsible for the rapid and precise positioning of the fuel rack, metering valve, or other fuel control element, directly governing the amount of fuel delivered to the engine and, consequently, its speed, load, and efficiency.

The core value of the WOODWARD 5501-465 lies in its dynamic performance, reliability, and integration within closed-loop control systems. It typically incorporates a power amplifier stage, feedback sensing (like an LVDT or RVDT) to monitor the actual actuator position, and sophisticated control logic to minimize the error between the commanded and actual fuel position. This ensures the engine responds correctly and swiftly to load changes or speed setpoint adjustments. For operators of generator sets, mechanical drive engines, and industrial turbines, the proper operation of the 5501-465 is essential for maintaining stable frequency, achieving fast load acceptance, and preventing hazardous conditions like overspeed or flameout. It is a key component that translates the control system’s «intent» into precise physical action, forming the critical final link in the fuel delivery chain for prime mover control.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

WOODWARD 5501-465

|

|

Manufacturer

|

Woodward, Inc.

|

|

Product Type

|

Fuel Control / Actuator Driver Module

|

|

Compatible Systems

|

Designed to work with Woodward governors and control systems (e.g., 2301A, ProAct digital series) for engine/turbine control.

|

|

Input Signal

|

Accepts a command signal from the primary controller, typically 4-20 mA, 0-5 V DC, or ±5 V DC, representing desired fuel valve position or fuel flow.

|

|

Output Drive

|

High-power output capable of driving proportional solenoids, torque motors, or the coils of electro-hydraulic actuators. Output may be a modulated current (e.g., 0-200 mA) or PWM signal.

|

|

Feedback Sensor Input

|

Accepts signal from a position feedback device on the actuator, commonly an LVDT (Linear Variable Differential Transformer) or RVDT, to close the positioning loop.

|

|

Control Loop

|

Implements a closed-loop position control algorithm (PID or similar) to accurately drive the actuator to the position commanded by the input signal.

|

|

Response Time

|

Very fast dynamic response to ensure stable engine control during transients.

|

|

Protections

|

Includes safeguards against: output short circuit, open feedback sensor, over-temperature, and possibly loss of input command signal.

|

|

Power Supply

|

Requires external DC power, typically 24 V DC or other voltage as specified for the actuator coil.

|

|

Status Indication

|

May include LEDs for power, fault, and enable status.

|

|

Mounting

|

Printed circuit board designed for installation within a control cabinet or on a dedicated mounting plate.

|

|

Operating Temperature

|

Industrial temperature range, typically -40°C to +85°C.

|

|

Environmental

|

Designed to withstand vibration and humidity common in engine and turbine environments.

|

Key Features and Advantages

WOODWARD 5501-465 is distinguished by its precision, robustness, and tight integration with Woodward’s control ecosystem. Its foremost advantage is providing high-fidelity, closed-loop position control of the fuel actuator. By continuously comparing the actuator’s actual position (via LVDT feedback) with the controller’s commanded position, it dynamically adjusts its drive output to eliminate error. This results in precise fuel metering, which is critical for maintaining steady engine speed, minimizing emissions, and achieving efficient combustion across the load range. Its fast response ensures the engine can rapidly accept or reject load without instability.

Built-in diagnostics and protective features enhance system reliability and safety. The module monitors the health of the feedback sensor (LVDT), detecting open or short circuits that would break the control loop. It also protects its own output stage from short circuits and thermal overload. These diagnostics can be communicated to the main controller to trigger alarms or safe shutdown procedures, enabling predictive maintenance. The module is engineered for the harsh electrical and physical environment of prime movers, with protection against voltage transients and designed to withstand significant vibration.

Application flexibility and ease of tuning are significant benefits. The 5501-465 can often be configured or tuned to match the specific characteristics of the actuator it is driving (gain, damping) and the connected engine’s response, allowing for optimal system performance. As a Woodward OEM component, it is designed to seamlessly interface with other Woodward control hardware, simplifying system integration and commissioning. For maintenance technicians, its modular design allows for straightforward testing and replacement. In summary, the 5501-465 provides the reliable, high-performance «muscle» needed to execute precise fuel control commands, which is fundamental to the stable, efficient, and safe operation of gas and diesel engines in demanding applications.

Application Areas

The WOODWARD 5501-465 fuel control module is deployed in systems requiring precise metering of fuel for internal combustion engines and gas turbines.

Its primary application is in engine governing for power generation:

-

Diesel and Gas Engine Generator Sets: Drives the fuel actuator (rack, valve) on standby, prime, or continuous power generators to maintain constant frequency under varying electrical load.

-

Gas Turbine Generator Control: Positions fuel valves on smaller industrial or mechanical drive gas turbines.

It is also used in mechanical drive applications:

-

Compressor Drive Engines: Controls engine speed to maintain desired discharge pressure or flow in gas pipeline compression stations.

-

Marine Propulsion Engines: Manages fuel delivery for main propulsion or auxiliary engines on ships.

-

Pump Drive Engines: For applications like irrigation or water flooding.

Essentially, the 5501-465 is found wherever a Woodward governor or control system is used to regulate the speed of a reciprocating engine or small turbine by directly controlling its fuel supply, typically in mission-critical industrial, power generation, and marine sectors.

Related Products

-

Woodward Primary Speed Controller/Governor (e.g., 2301A, ProAct): The device that generates the fuel command signal for the 5501-465.

-

Fuel Actuator (Hydraulic or Electronic): The final control element (e.g., Woodward SPM-A actuator) that the 5501-465 drives.

-

LVDT or RVDT Position Sensor: Mounted on the actuator to provide position feedback to the 5501-465.

-

Woodward Control Cabinet/Panel: The enclosure housing the module and other control components.

-

Power Supply Unit: Provides the DC power for the 5501-465 and the actuator coil.

-

Woodward ToolKit Software: May be used for configuring and monitoring parameters of the overall control system, which may include settings related to the driver module.

-

Solenoid Driver / I/O Modules: Other types of output modules in the Woodward system for different functions.

Reviews

There are no reviews yet.