Description

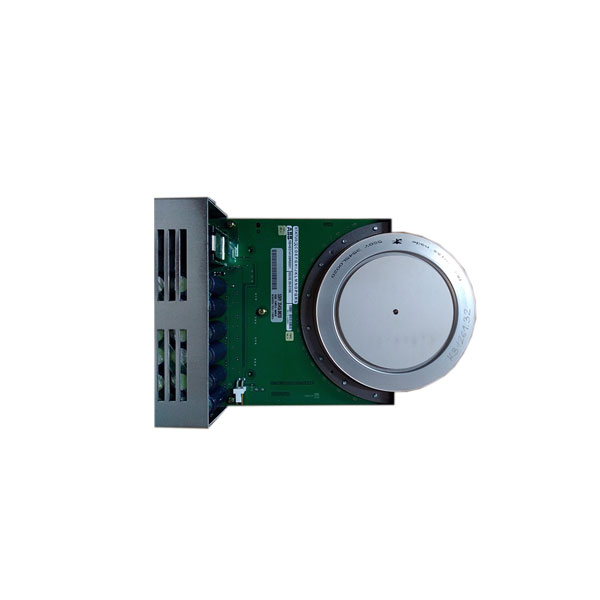

ABB PU515 (3BSE013063R1) — Power Supply Module

Product: PU515, Power Supply Module

Order Code: 3BSE013063R1

Manufacturer: ABB

Primary Application: A power supply module designed for ABB’s S800 I/O system, specifically for providing regulated DC power to S800 I/O modules installed in industrial automation and process control systems.

1. Core Overview & Positioning

The ABB PU515 is a dedicated power supply module within ABB’s S800 I/O modular system. It is a critical infrastructure component that converts the incoming plant power (typically 24V DC or 115/230V AC) into clean, stable, and isolated DC voltages required for the operation of the intelligent I/O modules (like AI, DI, AO, DO cards) and their field-side circuits.

Key Philosophy: It provides a reliable, compact, and DIN-rail mountable power source specifically engineered for the S800 I/O platform. Its design ensures that sensitive measurement and control signals are not affected by noise or fluctuations from the raw plant power supply.

2. Key Features & Functions

-

Dual-Isolated Outputs: Typically provides two completely isolated DC output voltages:

-

Logic/System Supply (+5V DC): Powers the internal electronics and communication circuits of the S800 I/O modules.

-

Field/External Supply (+24V DC): Provides a separate, isolated 24V source for powering the field side of the I/O modules, which in turn powers connected sensors (for DI/AI) and actuators (for DO). This isolation protects the system from field-side electrical noise and faults.

-

-

Wide Input Voltage Range: Designed to accept a broad range of input voltages, making it suitable for various global standards. Common input specifications include 24V DC, 115/230V AC, or a universal AC/DC input (e.g., 24-240V AC/DC).

-

Overload and Short-Circuit Protection: Includes electronic protection on its outputs. In case of an overload or short circuit on the field side, the supply will current-limit or shut down to prevent damage, and then automatically restart when the fault is cleared.

-

Status Indication: Features LED indicators to show the status of the input power and the health of the +5V and +24V outputs (e.g., green for OK, red/yellow for fault).

-

DIN-Rail Mountable: Compact design for easy installation on standard DIN rails within control panels.

-

Hot-Swappable (in some systems): In redundant power configurations, it can be designed to be replaced without shutting down the entire I/O station.

3. Model Number & Order Code Analysis

Common Technical Specifications (Inferred for PU515):

-

Input Voltage: Likely a wide-range AC/DC input (e.g., 24-240V AC/DC) to provide maximum flexibility.

-

Outputs:

-

System Voltage: +5V DC at a specified current (e.g., 3A).

-

Field Voltage: +24V DC at a specified current (e.g., 3A).

-

-

Output Power: Total power rating typically in the range of 50-100 Watts.

-

Isolation: 1500V AC or higher between input, outputs, and chassis for safety and noise immunity.

-

Protections: Overvoltage, overcurrent, and short-circuit protection on outputs; over-temperature shutdown.

-

Efficiency: High efficiency (>85%) to minimize heat generation.

4. System Integration & Architecture

-

Role in S800 I/O Station: The PU515 is the central power hub for a local cluster of S/O modules. It is typically mounted on a DIN rail alongside the I/O modules and a communication interface (like a CI867 PROFIBUS module).

-

Typical Wiring:

-

Input: Connected to the plant’s unregulated 24V DC bus or directly to an AC source via a line filter/fuse.

-

System Output (+5V): Connected to the backplane or bus of the S800 station to power the internal logic of all I/O cards.

-

Field Output (+24V): Distributed via a terminal block to the «L+» terminals of the individual I/O modules to power connected sensors and actuators.

-

-

Redundant Configurations: For high-availability systems, two PU515 modules can be configured in parallel (using optional diode modules) to provide N+1 redundancy. If one fails, the other seamlessly takes over the entire load.

5. Typical Applications

The PU515 is used wherever an S800 I/O station is deployed, which includes:

-

Process Automation (DCS): Distributed I/O stations in ABB 800xA or Legacy Advant systems.

-

Factory Automation: Machine control panels using S800 I/O connected to a PLC (e.g., via PROFIBUS with a CI867 module).

-

Any application requiring reliable, isolated power for a bank of ABB S800 analog and digital I/O modules.

Reviews

There are no reviews yet.