Description

Product Overview

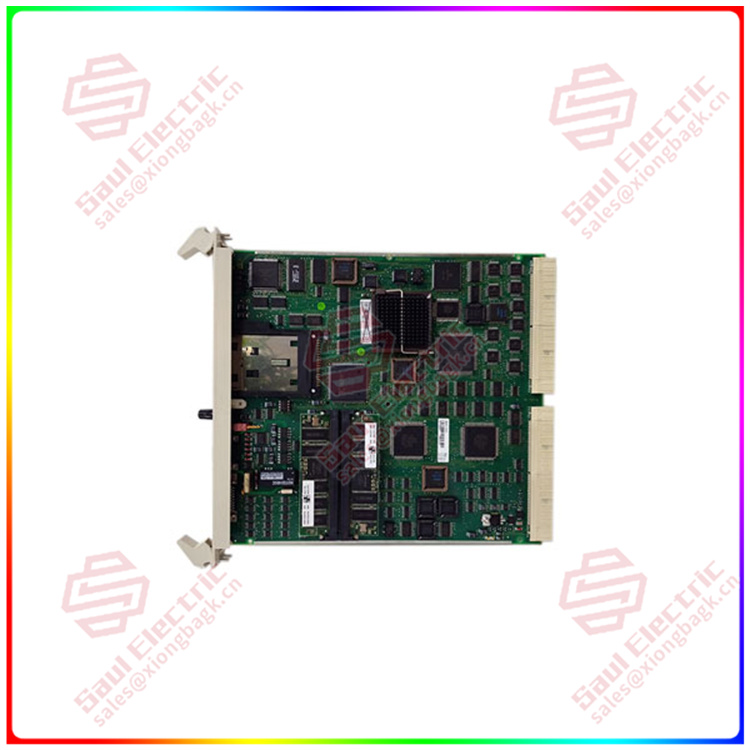

The ABB 3BSE011180R1 (SE071005AK / PM511V08) is a high-performance, certified AC 800M PM511 Safety Controller Module, a core component of ABB’s leading AC 800M High Integrity (HI) series. This specific model represents a powerful and certified controller within this series, specifically engineered for Safety Instrumented Systems (SIS) and critical control applications, capable of meeting Safety Integrity Level (SIL) 2/3 requirements according to IEC 61508/61511 standards. The controller acts as the main processor, executing complex, certified safety logic within a High Integrity architecture. Its primary function is to run user-programmed safety applications, process input signals via dedicated safety I/O modules (e.g., CI532), execute predefined safety logic (e.g., Emergency Shutdown ESD, Burner Management BMS, Fire & Gas detection F&G), and drive outputs to perform safety actions (e.g., close valves, trip pumps). The suffixes

SE071005AKand PM511V08typically refer to firmware revisions, hardware revisions, or specific market/configuration codes.The core value of this controller lies in its certified safety architecture, high reliability, and powerful engineering capabilities. It features a dual-processor architecture that supports redundant checking of program execution and memory. Its design ensures that upon detection of a hardware or software fault, the controller can transition to or remain in a predefined safe state. For engineers in industries such as oil & gas, petrochemicals, power generation, and pharmaceuticals, the ABB PM511V08 is the cornerstone for building certifiable safety systems. It enables the development and deployment of certified safety applications using IEC 61131-3 standard programming languages (like Function Block Diagram and Ladder Diagram) within an integrated engineering environment (Control Builder M), thereby protecting personnel, the environment, and assets.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

ABB 3BSE011180R1 (SE071005AK, PM511V08)

|

|

Manufacturer

|

ABB

|

|

Product Series

|

AC 800M High Integrity Series

|

|

Product Type

|

Safety Controller Module (Main Processor)

|

|

Safety Certification

|

Suitable for SIL 2/3 applications (per IEC 61508/61511), TÜV certified.

|

|

Processor Architecture

|

Dual-processor, supporting runtime checking and redundancy to ensure safety integrity.

|

|

Memory

|

Substantial user program and data storage (Flash and RAM).

|

|

Programming Standard

|

IEC 61131-3 compliant, supporting Function Block Diagram (FBD), Ladder Diagram (LD), Structured Text (ST), etc.

|

|

Communication Interfaces

|

Built-in Ethernet port (for engineering, operator system connection, and inter-system communication), supporting protocols like Modbus TCP/IP and OPC. Communicates with other safety controllers or I/O systems via dedicated safety communication (e.g., redundant safety networks based on IEC 61784 CPF).

|

|

I/O Connection

|

Connects to certified safety I/O modules (e.g., CI532 analog output, DI532 digital input) via a high-integrity I/O bus (e.g., S800 I/O).

|

|

Real-Time Clock

|

Integrated, with battery backup.

|

|

Power Supply

|

24 V DC input.

|

|

Operating Temperature

|

0°C to +60°C.

|

|

Certifications

|

TÜV, cULus, ATEX / IECEx (when installed in a certified enclosure), CE.

|

Key Features and Advantages

ABB PM511V08 (3BSE011180R1) excels through its certified safety architecture and powerful engineering environment. Its dual-processor design and built-in self-diagnostics can detect processor, memory, and communication faults, ensuring the system transitions to a safe state upon detection of a dangerous failure. This architecture is fundamental to achieving SIL 2/3 certification, providing the necessary confidence for critical safety applications.

Powerful integration and engineering efficiency are significant advantages. The controller is an integral part of the ABB System 800xA or Advant MOD 300 Distributed Control Systems, enabling seamless integration with process control systems for data exchange and coordination between safety and process control. Programming is performed within ABB’s unified Control Builder M engineering tool, which supports the development of both safety applications and standard process applications, thereby streamlining the engineering workflow, reducing training needs, and minimizing configuration errors.

High availability and flexible deployment options enhance its practicality. The controller supports various high-availability configurations, including cold standby and hot standby redundancy, to maximize system availability and reduce unplanned downtime. Its modular design allows for flexible system expansion. For safety system engineers, the ABB PM511V08 provides a reliable, certifiable, and easily integrated platform for implementing complex safety functions while meeting international safety standards and simplifying the entire engineering lifecycle.

Application Areas

The ABB PM511V08 safety controller is designed for industries requiring certified safety instrumented functions.

In the oil & gas sector, it is used for Emergency Shutdown Systems (ESD), Fire & Gas Detection and Mitigation Systems (F&G), and wellhead control on offshore platforms and onshore facilities. Within petrochemical and refining industries, it protects reactors, distillation columns, and compressors, executing Burner Management Systems (BMS) and high-pressure protection functions.

In power generation, it is applied in boiler protection and gas turbine control. For pharmaceutical and chemical batch processes, it ensures safety interlocks for batch reactors. Essentially, the ABB PM511V08 is the logic solver of choice for any process with a significant hazard requiring automated safety intervention to prevent harm to people, the environment, or assets, where that safety function needs to be certified to SIL 2 or SIL 3.

Related Products

-

ABB AC 800M HI Safety I/O Modules (e.g., CI532, DI532, DO532): Certified input/output modules that interface with the controller.

-

ABB S800 I/O Baseplate (e.g., TU847): The hardware unit that houses the I/O modules.

-

ABB Control Builder M Professional Engineering Software: The tool used for programming, configuring, and commissioning the PM511 controller and its associated I/O.

-

ABB System 800xA or Advant MOD 300 System: The DCS platforms with which the safety controller can be integrated.

-

ABB Safety Communication Modules/Gateways: For connecting different safety systems or communicating with higher-level networks.

-

ABB Redundant Power Supply Modules: To power the controller and I/O in high-availability configurations.

-

Certified Sensors and Actuators: The field devices that provide input signals and carry out safety actions.

Reviews

There are no reviews yet.