Description

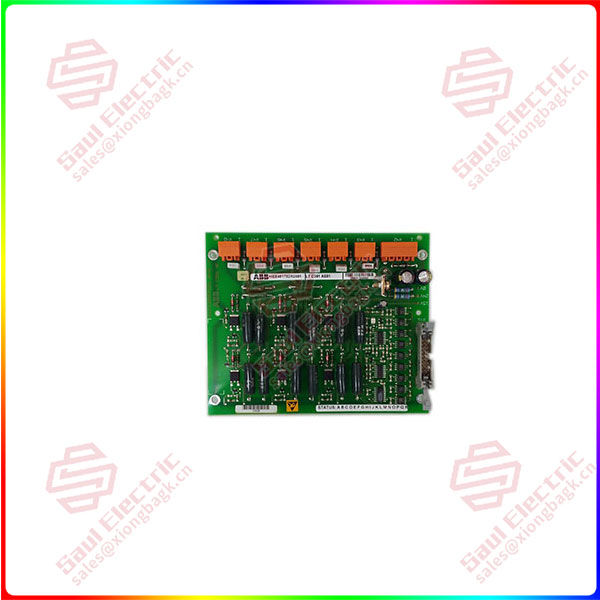

ABB LTC743CE (3BHE013299R0001) — Technical Overview

Product: LTC743CE — Process Controller / Loop Controller Module

Manufacturer: ABB

Order Code: 3BHE013299R0001

Primary Application: A high-performance process controller module used in ABB’s Advant / MOD 300 or Symphony DCS (Distributed Control Systems) for continuous process control in power generation, oil & gas, and chemical industries.

1. Core Overview & System Context

The ABB LTC743CE is a digital loop controller designed for regulatory control applications. It belongs to ABB’s legacy but highly reliable Advant/MOD 300 or Symphony Harmony/Infinity series control systems. It operates as a standalone controller or as part of a distributed control architecture, executing PID control, logic sequences, and arithmetic functions for critical process loops.

2. Key Features & Functions

-

Multi-Loop Control: Capable of executing multiple control algorithms (typically 4, 8, or more loops) within a single module.

-

Advanced Control Algorithms: Implements standard and advanced PID functions with auto-tuning, cascade, ratio, and feedforward control capabilities.

-

Integrated I/O Interface: Connects directly to field signals via associated I/O modules or a dedicated I/O bus. It handles analog inputs (AI), analog outputs (AO), digital inputs (DI), and digital outputs (DO).

-

Communication & Integration:

-

Integrates seamlessly with ABB’s Advant/ MOD 300 or Symphony DCS via the MasterBus or INFI-NET communication networks.

-

Supports peer-to-peer communication with other controllers for complex interlocking and sequence control.

-

-

Redundancy Support: Can be configured in hot-standby redundant pairs for high-availability applications.

-

Programming & Configuration: Configured using ABB’s engineering tools (e.g., Control Builder or legacy Composer tools). Employs function block diagram (FBD) or ladder logic (LD) programming.

3. Common Technical Specifications

-

Processor & Memory: Features a dedicated microprocessor with non-volatile memory for storing control strategies and parameters.

-

Control Execution: Deterministic, high-speed scan time suitable for fast process loops (e.g., pressure, flow control).

-

I/O Handling: Interfaces with ABB’s standard I/O modules (e.g., DSQC series) for signal acquisition and output.

-

Communication Ports:

-

System Network Port: For integration into the DCS (e.g., INFI-NET).

-

Service/Engineering Port: For local configuration and diagnostics (often RS-232/485).

-

-

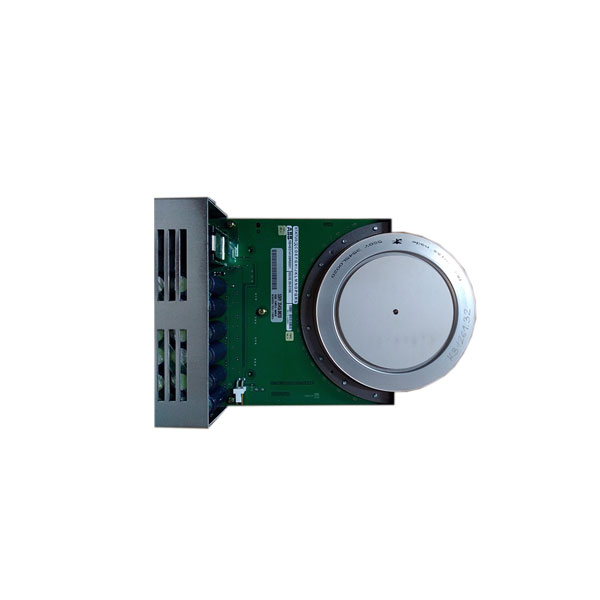

Physical Form: A single-slot module designed for mounting in ABB’s standard AC 800M or Advant controller rack/enclosure.

-

Power Supply: Powered by the system backplane (typically 24V DC).

4. System Integration & Architecture

-

Role in DCS: Acts as a distributed processing unit within ABB’s control hierarchy. It offloads control tasks from the central station, enhancing system reliability and responsiveness.

-

Typical Configuration:

-

The LTC743CE resides in a controller rack.

-

It communicates with the Operator Station (OS) and Engineering Station (ES) via the system network.

-

It reads process variables from field I/O modules connected to sensors.

-

It executes the control logic and sends output signals to final control elements (valves, drives) via output modules.

-

-

Redundancy: In critical applications, a second LTC743CE module can be installed as a standby. If the primary fails, the secondary takes over automatically without process disruption.

5. Typical Applications

-

Boiler Control: Combustion control, feedwater regulation, steam temperature control.

-

Turbine Control: Speed/load control, auxiliary system sequencing.

-

Compressor Control: Anti-surge control, performance regulation.

-

Chemical Process Control: Reactor temperature/pressure control, distillation column control.

-

General PID Loop Control: For pressure, flow, level, and temperature loops.

Reviews

There are no reviews yet.